This year, pv magazine pledged to place the issue of sustainability in the solar and energy storage industries at the heart of our reporting and events via the UP initiative. In addition to running quarterly themes, which examine key issues like the use of lead in solar modules (Q4 2019), we are also holding webinars on topics like greenwashing, and have ramped up our general reporting on a host of other sustainability issues. In 2020, our global series of round table events will also help the initiative step UP even further.

Another part of UP is the launch of an annual sustainability award, where we aim to recognize green leaders who are working to develop products that not only go on to generate clean energy, but which are also setting a new, green, status quo when it comes to manufacturing products and developing employment practices, for instance.

A number of diverse companies submitted entries, among them module manufacturers, testing labs, and floating solar installations. It was no easy task to come to a final decision, because on the one hand, there is a lack of common sustainability standards and criteria that solar and storage companies can follow to quantify their sustainability credentials. And on the other hand, it’s tough because many appear to be making a strong effort to create a better world. And indeed, in the end, the jury couldn’t settle on one company, given that the two top contenders – while utilizing different technologies – both have worked hard to weave sustainability into the fabric of their operations and are actively engaged with the global community to take efforts even further. The jury also decided to highly commend one other entry.

The 2019 pv magazine sustainability award goes to:

First Solar Inc.

First Solar Inc.

Entry: First Solar Series 6

Sustainability has been central to First Solar since its inception in 1999. Andreas Wade, the company’s global sustainability director, told pv magazine this year that at that time, the director of the board – later its CEO – handed Wade’s predecessor a book, Cradle to Cradle (C2C): Remaking the way we make things, and told her that those principles should form the core of the company’s approach to design and recyclability. While First Solar cannot obtain C2C certification because it uses cadmium telluride (CdTe), it has been working with stakeholders ever since to validate its sustainability credentials in the face of controversy over CdTe, and to create comprehensive sustainability standards. This includes helping develop lifecycle assessment-based environmental footprint category rules for PV generation. It also participated in the PEF pilot, which evaluated the lifecycle environmental performance of five different PV technologies, and concluded that thin-film CdTe PV has the lowest environmental footprint of all assessed technologies. In addition, it created the first global PV recycling program in 2005. First Solar has also been publicly reporting to the Carbon Disclosure Project since 2011 – it received a score of B for both climate change and water, above the sector averages of B- and C, respectively. Finally, its Series 6 modules are said to boast the industry’s smallest carbon footprint (11-17 g CO2/ kWh), fastest energy payback time (<6 months), and lowest lifecycle water use (24 times lower than monocrystalline silicon). According to the award entry, “As a result of its larger form factor, efficient BOS structure, higher efficiency (17.5%), 27% less glass per watt, and 8% recycled semiconductor content, the environmental impacts of a Series 6 PV system are 10% lower than First Solar Series 4 modules and up to 4.5 times lower than c-Si PV.”

Jury comment:

This is a controversial case, because cadmium and tellurium are both toxic. However, an industrial society must be able to handle toxic materials and First Solar is a company I would trust with it. It has contingencies for recycling, and has participated in convincing lifecycle analysis studies suggesting that CdTe modules genuinely have a lower carbon footprint than the (also negligible) footprint of crystalline silicon. Despite attempts to smear the company with reports of toxicity events, none of the mud stuck. First Solar also helped to recycle leftover modules from bankrupt CdTe competitor Abound Solar. The challenge for First Solar now is to remain competitive with bifacial modules, an option that it cannot easily adopt, once the U.S. import tariffs go away.

“The environmental impacts of a Series 6 PV system are 10% lower than First Solar Series 4 modules and up to 4.5 times lower than c-Si PV.”

SunPower Corp.

SunPower Corp.

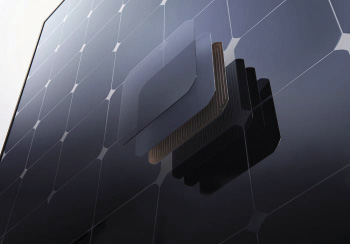

Entry: SunPower Maxeon Solar Panels (DC)

In 2014, SunPower was the first company, ever, to achieve C2C certification for a PV module, with its E- and X-Series. Overall, the panels received a “bronze” rating, which means the company could be doing more to achieve full cradle-to-cradle status, particularly in the areas of renewable energy and carbon management. However, like First Solar, SunPower has integrated sustainability into its corporate philosophy from the start, is transparent, and has been involved in a number of global initiatives to advance the solar industry. For example, its production facilities in Mexico and France have earned the “solar industry’s first” landfill-free verifications from NSF Sustainability. It was also a founding member of PV Cycle, has won the highest score on the Silicon Valley Toxic Coalition’s (SVTC) Solar Scorecard for the last three reporting years, and publishes an annual sustainability report. CEO Jef Walters told pv magazine that SunPower is the only solar company to have been accepted into the Declare Label program, which means it must state all materials used in its modules, their assembly location, life expectancy, and recyclability. One particular advantage that the company’s Maxeon modules hold over the large majority of its c-Si peers is the removal of lead and mercury from its production processes, meaning they can be more safely recycled. According to SunPower’s award entry, “Maxeon’s power density enables the industry’s smallest product footprint, generating the same power as conventional arrays with 30% fewer panels, creating ancillary sustainability benefits.”

Jury comment:

SunPower is a sustainability leader with great reporting lines, and ia a founding member of PV Cycle. The Maxeon module eliminates lead entirely and is likely to become best practice in future. SunPower also competes against commoditized, cheaper Chinese modules – one reason it now plans to spin its manufacturing operation off from the division that focuses on commercial and residential installations in the United States. It also helped pilot the Chemical Footprinting program developed by Clean Production Action.

Highly commended: DSM Advanced Solar B.V.

Entry: DSM Endurance backsheets

DSM’s Endurance backsheet, released in 2018, impressed the judges with its potential in both performance and sustainably. Comprised of a top layer of polyamide 12 (A), a polypropylene (PP) based core layer (O), and a polyolefinic inner layer (E), it is fluorine-free and utilizes a co-extrusion process, where the multiple layers are together pressed into a single piece, as opposed to lamination. This helps reduce the carbon footprint by 30% compared to conventional fluoropolymer backsheets, says DSM. Employing circular economy principles, the backsheets are said to be 100% recyclable and generate no production waste. Although current recycling technologies simply crush PV modules and separate out the glass and some metals, and other materials are either landfilled or burned, DSM’s Endurance backsheet doesn’t contain halogens or other hazardous materials, meaning it can be safely treated. The material’s thermoplastic nature means it can be safely re-melted, so waste trim is already recycled by packaging suppliers to make boxes, or other companies which make chairs. In 2018, the backsheet won an “All Quality Matters Award” from TÜV Rheinland. It has also been evaluated by engineering firm Black & Veatch, which concluded it may have a “positive effect on module performance and durability in the field.”

Jury comment:

What we especially liked was that the new Endurance non-fluoridated backsheet is designed to be fully recyclable. This embraces the spirit of this award, thinking to the future – and the cost is almost as low as that of Chinese rivals. There remain questions about whether the fluoride-free backsheet will have the weatherability of conventional backsheets, which only time and field testing are likely to fully answer.

Juror profiles

Jenny Chase – Manager Solar Insight,

Jenny Chase – Manager Solar Insight,

BloombergNEF

Jenny Chase joined BloombergNEF in 2005 and launched the Solar Insight Service in early 2006. She has overseen all research, including PV experience curve analysis, which enabled the team to forecast an upcoming sudden 35-40% fall in crystalline module prices a year before it happened. Earlier this year, she published her first book, Solar Power Finance Without the Jargon, which has been described as “a must-read for anyone interested in renewable energy and the energy transition.”

Sheila Davis – Executive Director,

Sheila Davis – Executive Director,

Silicon Valley Toxics Coalition (SVTC)

Sheila Davis spearheaded the first U.S. e-waste curbside collection programs. Her research and advocacy also led to a ban on hazardous electronic waste from California landfills and the passage of the first e-waste recycling legislation in the nation. SVTC launched the Sustainable Solar Initiative, and released the “Toward a Just and Sustainable Solar Industry” report. In 2009, SVTC also launched the Solar Scorecard, which ranks solar manufacturers on their environmental programs and practices.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.