Low-temperature perovskite solar module with 19.1% efficiency

Researchers have developed a PV module with with an efficiency of 20.72%, based on tin oxide (SnO2) as an electron transport layer, an organometal halide perovskite layer, organic halide salt phenethylammonium iodide (PEAI) as a passivation agent, and Spiro-OMeTAD as the hole transport layer (HTL).

Carbon-based, HTL-free perovskite solar cells with 26% efficiency

An international research team has designed a carbon-based perovskite solar cell without a hole transport layer. Two plasmonic nanoparticles – Ag@SiO2 and SiO2@Ag@SiO2 – were added to the cell photoactive layer, in addition to a copper(I) thiocyanate (CuSCN) interlayer at the perovskite-carbon interface.

Tin perovskite solar cell with operational stability of over 1,300h

Scientists in Spain have built a 10.61%-efficient tin perovskite solar cell with improved open-circuit voltage and stability. The device was fabricated with formamidinium tin iodide (FASnI<sub3), sodium borohydride (NaBH4) as a reducing agent, and a bulky secondary ammonium cation of small size known as dipropylammonium iodide (DipI).

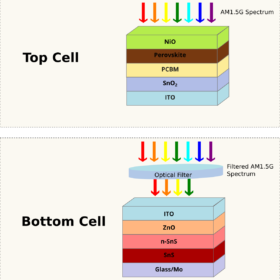

Double-junction perovskite-tin sulfide PV cell design with up to 28.92% efficiency

An Iranian-Italian research group has simulated a double-junction tandem solar cell based on perovskite and tin sulfide. They said that it can reach an efficiency rating of between 22.9% and 28.92%.

Terahertz, microwave spectroscopy for more accurate PC cell assessments

A German research group has used spectroscopic methods based on terahertz or microwave radiation and has discovered that they might help with more precise assessments of the characteristics and performance of solar cells. Their proposed approach purportedly enables the evaluation of maximum possible efficiency levels for emerging materials such as perovskites in solar cells.

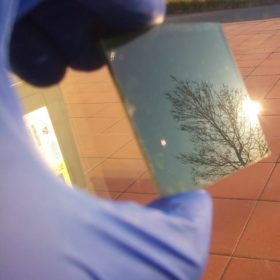

Semi-transparent perovskite solar cell with 13% efficiency, 27% transparency

Developed for applications in BIPV, vehicle-integrated solar and smart glasses, the solar cell was built with an ultra-thin, semi-transparent, triple-cation perovskite film and gold nanorods (Au NRs). The device achieved an open-circuit voltage of 1097.1mV, a short-circuit current of 17.11mA/cm2 and a fill factor of 73.12%.

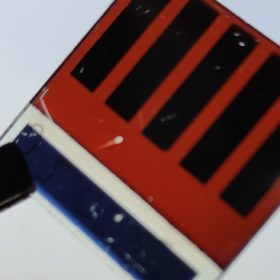

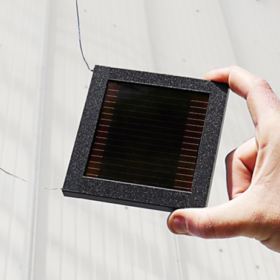

Mini perovskite solar module with 40 sq cm aperture area, 17% efficiency

The 19.2%-efficient perovskite cells used in the module rely on an electron layer based on tin oxide that was deposited via chemical bath deposition. This technique, according to the device’s creators, has made it possible to have a relatively small drop in efficiency from small cells to the 40cm2 module.

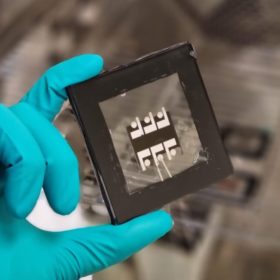

Damp heat–stable perovskite solar cell with 24.3% efficiency

Developed by scientists in Saudi Arabia, the perovskite cell was able to retain over 95% of its initial efficiency after 1,000 hours at damp-heat test conditions. The cell was fabricated with a substrate made of glass and indium tin oxide (ITO), 2D layers, a 3D perovskite layer, an electron-selective layer, a buffer layer based on bathocuproine (BCP), and silver metal contact.

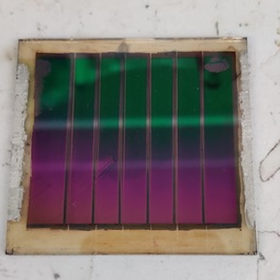

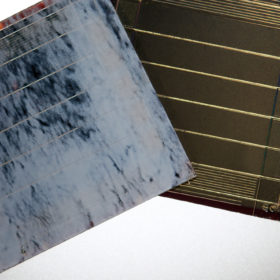

Small-area, colored perovskite BIPV module with 13.9% efficiency

Through a conventional coloring technique for crystalline solar modules, scientists in Germany were able to manufacture a colorized small perovskite solar module in white marble optic displays that maintains up to 88.5% of the efficiency it had before coloring. The device was built with five cells interconnected in series and has a total area of 9cm2.

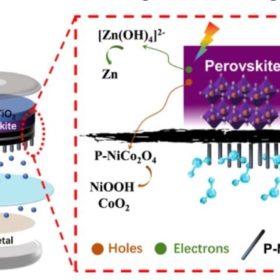

PV-powered rechargeable aqueous zinc battery

Conceived by scientists in China, the device combines an integrated carbon-based perovskite solar cell module with a rechargeable aqueous zinc metal cell. The proposed system achieved an overall efficiency of 6.4%, and a steady operation for more than 200 cycles with little performance degradation.