Australian solar module manufacturer commits to recycling strategy

Reclaim PV has added another partner to its national solar panel recycling and recovery program with South Australian-based manufacturer Tindo Solar committing to a program that will see close to 100% of the solar PV panels that it handles recycled and re-used in the industry.

New tech to recover pure silicon from end-of-life solar cells

An Indian research group has used three different chemicals instead of commonly used hydrofluoric acid to separate silicon from the cell. The technique is claimed to be able to deliver recycled silicon with a purity of up to 99.9984%.

Increasing volumes for PV module recycling in Brazil

Brazilan PV module recycling specialist SunR has already recycled 30 tons of panels and expects to receive another 125 tons. According to its CEO, demand for recycled panels, especially broken panels, has increased considerably in recent years.

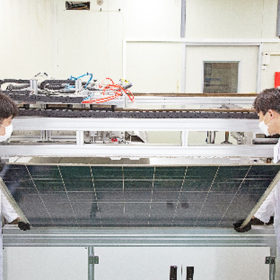

Novel PV module recycling tech from South Korea

Developed by the Korea Institute of Energy Research (KIER), the “non-destructive” technology is claimed to enable the recovery of 100% of a module’s glass and to allow the reuse of silicon for producing new solar cells with an efficiency of 20.05%.

A mechanical technique for PV module recycling

An Italian consortium has developed a panel recycling process it claims can recover up to 99% of raw materials. The developers claim their technique takes only 40 seconds to fully recycle a standard panel, depending on size and recycling site conditions.

More than 5,000 tons of modules collected for recycling in France

PV Cycle has said it collected more than 280,000 solar panels at the end of their lifecycle in France last year, including 200 tons from the nation’s overseas territories.

PV waste a rising challenge for Bangladesh

With concerns over the mountains of PV system waste that will one day pile up around the world, Bangladesh is no exception – the nation currently has no solar panel recycling policy.