Cutting out cadmium for a 16.7%-efficient flexible thin-film solar cell

Scientists in Japan have developed new processes for CIGS solar cell manufacturing, entirely eliminating the use of cadmium and replacing a waste-intensive wet chemical stage. With a thin film deposited on a flexible steel substrate, the group achieved 16.7% efficiency, which it says is a record for a cell of this type produced using scalable fabrication processes.

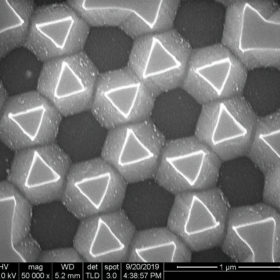

Nanostructures for ultrathin flexible wafer

Scientists in South Korea combined two processes to etch a nanostructure of tiny pyramids onto the surface of a silicon wafer. As well as trapping more light and increasing the cell efficiency, the group claims that its nanostructure improves the mechanical flexibility of the cells. This could potentially allow for the use of much thinner silicon wafers than is currently possible in production.

RENA picks up 15 GW equipment order

Germany based PV equipment supplier RENA Technologies has received what it describes as its ‘biggest ever order’, from a tier 1 manufacturer in Asia, for 15 GW of its wafer texturing equipment. Financial details of the deal have not been disclosed, although the company states that the order is worth “tens of millions of euros.”