Siemens Energy is #UPrising

Today at @Intersolar Europe, pv magazine launched our #UPcampaign. We are advocating for the demonstration of the #solar industry to unite around sustainability for an #UPrising movement. We spoke with @Siemens_Energy’s Andreas Boes to talk about their zero fossil fuels project. pic.twitter.com/2QM5jw9Qvr

— pv magazine (@pvmagazine) May 15, 2019

Suntech’s take on the trade war

The Chinese solar industry will suffer little harm even if President Trump follows through on his threats to pile more imports on Chinese tariffs, according to Vincent Cao, VP for global sales at Chinese PV manufacturer Suntech.

“Suntech has very few volumes shipped to the United States in the last few years,” Cao told pv magazine live, “so even if they have a trade war between China and the United States, even if they have an import price tax imposed, there’s a very limited impact on Suntech’s business.

“All the product we ship to the United States is from Vietnam, so there’s another kind of story.

“At Trina, Jinko, they manufacture shipments from Malaysia, Thailand, Vietnam.”

Asked whether there was a danger Trump could widen the net on imports, Cao replied: “Trump is very unpredictable, he’s a crazy guy. Sometimes he’s: ‘Okay, the modules from Chinese makers also from Malaysia will pay 25%’ Who does that?”

Impressive timing as Jinko secures innovation honor

As far as launches go, it doesn’t get much better than receiving the news the product in question has bagged an award while the support staff are setting up the presentation stage.

That’s what just happened over at the Jinko Solar stand, where the Swan Bifacial HC module was announced winner of the Innovation Award at Intersolar 2019.

That lent some credence to claims the 380-400 W module, featuring a clear Tedlar-based backsheet from DuPont, can offer a power output 5-25% higher than its peers.

It was enough to prompt Jinko’s general manager for Europe, Frank Niendorf, to predict big things for bifacial – and he’s certainly not alone in that respect at this year’s show.

“Within the next three years, 30 or 40% of the market will be bifacial – at least. That’s a conservative estimate,” he announced to a sizable crowd.

Which would be good news for main supply partner DuPont. “If the bifacial technology is aiming for 30-40% of the global market,” said DuPont’s Stephan Padlewski, “then, with use of a clear backsheet, we won’t be a niche part of that segment, we want to be mainstream.”

With Jinko confident a bifacial module which is 9kg lighter than its glass-glass rivals will mop up, Niendorf said the new product justified the Chinese manufacturer’s decision to move away from beating rivals on price and to focus on quality.

“Jinko’s strategy to move from a former cost leader to a new tech leader is successful,” he said. “We decided a few years ago to significantly invest in R&D.”

This blogpost was amended on 22/05/19 at DuPont’s request to capitalize ‘Tedlar’.

Daisy chaining with Fronius

At a very busy booth, Austrian inverter manufacturer Fronius presented two new inverters at Intersolar Europe. Squeezing myself through the crowds, I managed to get a glimpse of them. The product for the residential market, the Primo Gen 24 Plus, features a technology called PV point. In the Queen's English this means the inverter can maintain emergency power supply, while neighbors have to sit in the dark.

“The clue is that the system offers a really cost efficient way to provide emergency power supply without any extra power electronics of storage,” says Volker Haider, Product Marketing, Training & Education Business Unit Solar Energy, at Fronius International GmbH.

The system will then feature a single wall plug with 3 kW that can continue operations. That should be enough oomph to keep some beers cold to impress the neighbor. According to Haider, the inverter can easily be wired up to a storage system without complication, and then provide full on back-up power.

Also on the C&I or utility scale front, Fronius is offering some innovation. The new Tauro can be wired in a way to reduce the number of AC combiner boxes and reduce cabling costs. The tech is called Daisy Chaining and has been installed at Fronius multi MW installation in Greece. No beer cooler was hooked up to that system, as far as I know.

The secrets of anti aging

For mid-May is actually surprisingly cold in Munich today, but that does not mean project developers can forget about inverter cooling qualities.

Gamesa Electric has launched its new PV 3750 central inverter. The machine features a special cooling system combining air-to-air heat exchangers and air-to-liquid heat exchangers. This type of cooling system is only used by three companies in the world Enrique de la Cruz, Solar and Storage sales director at Gamesa Electric, tells pv magazine. “We have used this technology in the wind sector for many years,” he says.

Hot and dusty places like the Middle East, Spain or LatAm are good contenders to make use of this piece of equipment. And much like food in the fridge, well chilled components inside the inverter don’t spoil fast, and that helps with overall reliability of the system.

I guess being well chilled in mid-May prevents me from aging fast. Let’s hope Enrique is right!

Complicated rooftop markets

“We are tapping the more complicated rooftop market, now.” That is how Andreas Schmidt, head of marketing for the EMEA region with Delta introduced the company's new M70A string inverter. For the first time, the company is using six MPPT channels. In so doing, Delta can now also serve customers that have complicated roof structures with a lot of pesky diagonals and other obstructions.

Other highlights include a design, which feeds DC and AC cabling from the left and right, respectively. Schmidt says this allows the inverter to be placed on the floor upright, while competitor products often have to be wall mounted, as cabling is connected from the bottom. With some array layouts, where space is limited because of the building structure, this could be an advantage.

“A module for every array”

JinkoSolar Chief Marketing Officer Gener Miao treated pv magazine to a preview of the new bifacial Swan module earlier today, one of the first bifacial modules to incorporate a transparent backsheet, rather than the glass-glass setup that has dominated the first wave of bifacial module production.

According to Miao, the transparent backsheet will make things much easier for installers, thanks to lighter weight and a frame for easier clamping. He also noted that the backsheet allows for faster heat dissipation than glass, keeping the module operating temperature lower.

Jinko will, however, also continue to produce glass-glass bifacial modules, with Miao noting that having the best performing module for any particular array means focusing on more than one technology, and that in floating PV installations for example, glass-glass might still be an ideal option.

The company has confirmed three orders for utility-scale projects featuring the module already, and while Miao would not be drawn on how much production capacity will initially be devoted to the Swan module, he points out that since no special equipment is needed to produce the module, only a straight swap from white to transparent backsheet material, technically all of the company’s module capacity could be put to use for this module without any changes.

Miao further outlines big expectations for Europe in 2019, driven by the falling cost of deploying solar: “Within Europe there are a lot of opportunities for grid parity projects, and we see that moving very fast.”

REC displays its Alphα side

Module launches are par for the course at Intersolar, and 2019 is proving no exception. What feels different this year is that manufacturers are pushing efficiency upwards at greater pace, and taking more risks when it comes to adopting new module technologies.

REC’s Alphα module series launch, at 4pm this afternoon, is another indication of this trend. The Singapore-based manufacturer adopting heterojunction (HJT) cell technology, alongside half cut cells, dual module format, and with Smartwire cell interconnection. The module comes with a power output ranging from 360W to 380W in a 60-cell configuration – showing that the combination of high efficiency approaches does pay off.

REC has long been an innovator in module technology, with its TwinPeak series having picked up previous Intersolar awards, and leading the field in dual module design and half-cut cell adoption. For REC CTO Shankar Sridhara, going HJT on the cell front was a logical next step.

“The main thinking was REC, with its size of around 1.8 GW, we can’t compete with the normal technology which is now mono PERC. With the n-PERT, which we launched last year, we are slightly ahead… but in order for us to be competitive… we have to maintain a significantly larger distance. HJT the correct technology to do that both from a performance and a cost perspective.”

The HJT and Smartwire technology comes courtesy of Meyer Burger – and its team attended the launch this afternoon. REC has placed a 600 MW order with the Swiss equipment provided for the HJT tooling. It expects to have received the production equipment and to begin ramping in October or November of this year.

Sridhara says that on a cost front, he has been impressed with the yield that the company has been able to achieve on the Meyer Burger HJT line in Germany, on which Meyer Burger allows partners to test and develop their products. In terms of Smartwire, he reports that it allows REC to move towards thinner wafers in the future.

“It has been a very interesting reaction from people [to the new module],” says Sridhara. “They have been surprised because it is a bold move jumping to HJT. It is also a very bold doing 600 MW in one shot. But we are confident about the due dilligance that we did, and the module development that we have done.”

Not surprisingly, REC is targeting the residential and C&I market segment with the Alphα. It says it already has orders from installation partners in Germany, Australia, France, Italy, Netherlands and the United States.

And then, the bar opened.

6 points to push Indian solar

At this afternoon’s Indo-German Energy Forum, Bridge to India’s Vinay Rustagi outlined six points to push India’s solar industry towards its ambitious goals:

- Stop the fixation with prices. “It is a mistake to focus just on price,” he said. The conversation needs to shift towards one of higher quality, more reliability and better performance. He added that in the current climate, only the largest developers can survive; if there were smaller tenders with a more distributed focus, the smaller and medium sized developers would be attracted to the market again.

- Prioritize distributed solar. India’s southern belt, in particular, is saturated with massive utility-scale projects. The priority should now be smaller, more scattered solar projects of 5-10 MW, rather than the big solar parks. Overall, he sees big growth potential in the C&I segment in particular, and said that the residential sector, which to date has not achieved its set targets, will surprise the industry in a few years as it continues to grow. Off-grid, meanwhile, is a “missed opportunity”, he said, particularly in a country like India. “It should have exploited the potential,” he said.

- Act proactively on the issues of land acquisition and transmission.

- Act urgently on grid integration. This should include issues like ancillary services, storage technology, flexible thermal power plants, and demand side management.

- Change PPA structures and risk allocation. “It’s time to shift the risk away from the transmission companies to the developers,” said Rustagi.

- Visibility on manufacturing policy. It is time for the government to take decisive action, setting a long-term visible policy, where there is no risk for the developers, he said.

He added that India’s scale, openness and transparency are serving to pull in investors. However, the market is at a junction, where it is now time to take stock of policies and redirect the path forward. Unless this is done, the country’s renewable targets will not be achieved.

The topic of decentralization was also touched upon the Ministry of New and Renewable Energy’s Jeevan K. Jethani, who said the distribution network is not strong enough to take on much more solar in the daytime. Decentralized energy is one solution to this issue, particularly in the agriculture sector. Here, Bridge to India’s Rustagi said that the new initiatives unveiled by MNRE could be a “game changer”. He said the challenges, however, lie in the fact that the schemes are subsidy based and, thus, inefficient, with the successes difficult to predict and lots of paperwork.

Pranav R Metha from the National Solar Energy Federation India (NSEFI) said that India is looking to tender a further 30 GW of solar in the next two years.

Meanwhile, Shri Sugandh Rajaram from the General Council of India, whose job it is to promote India abroad said that business in India has become easier. This is evident in the fact India jumped 65 places in the World Bank’s ease of Doing Business Report, he said. Examples include using digitalization and online transactions to make processes faster, and reducing costs in the form of the Goods & Services Tax (although I am not sure that everyone agreed on this last point).

Rajaram added that India will reach its 2030 goal of procuring 40% of its power from renewables three years early.

Suntech on Trump

I swung by the Suntech stand here in Munich and caught up with Vincent Cao, the Chinese manufacturer’s VP for global sales.

He shared his thoughts on the prospect of an escalating trade war between China and the U.S. and its potential effect on the solar manufacturing industry.

Right now I need to dash off to see what all the buzz is surrounding Jinko Solar’s new module but after that we’ll come back to trade tit for tat and, as a teaser, I’ll leave you with Cao’s assessment of President Trump: “He’s a crazy guy”.

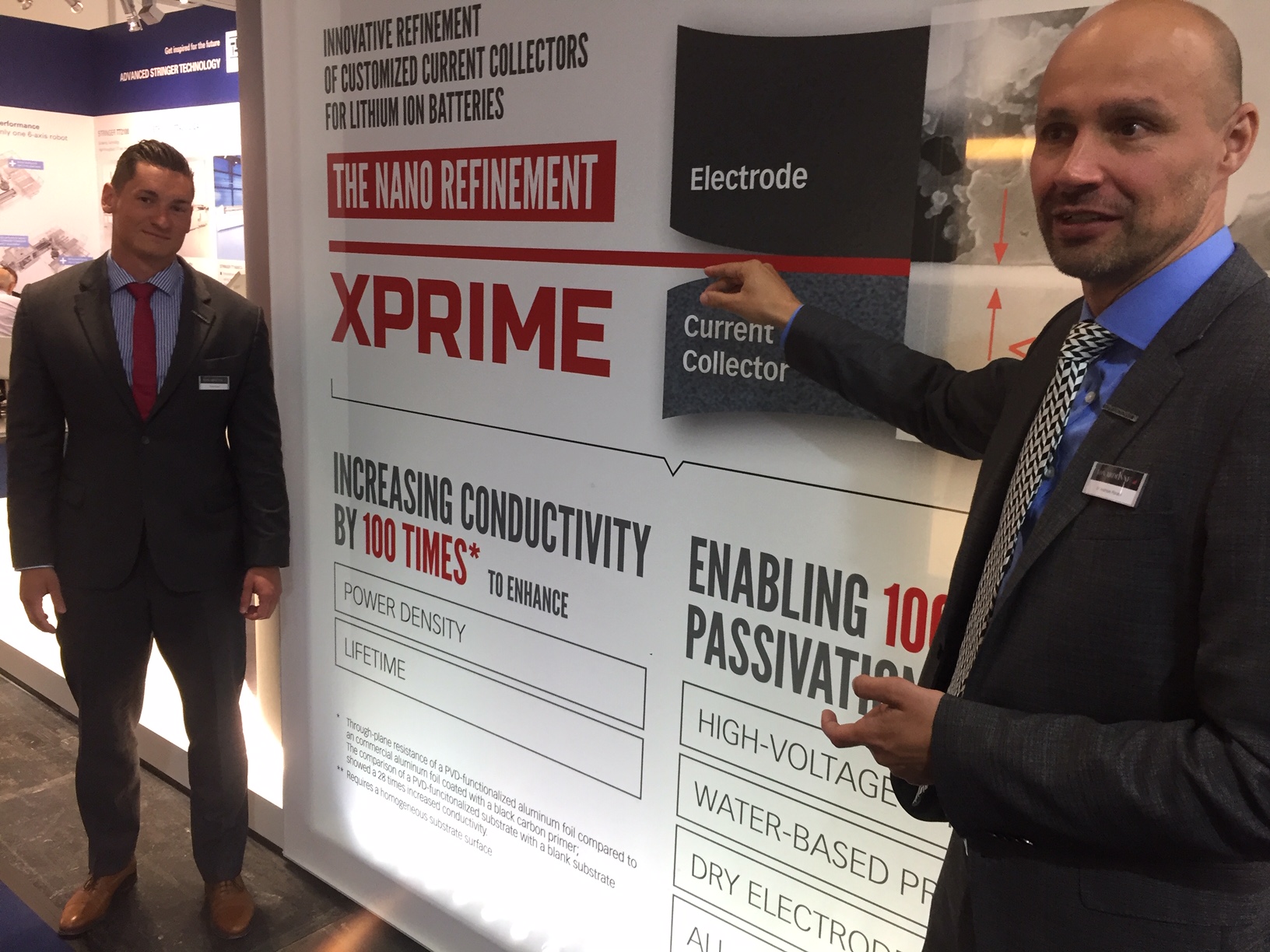

I’ll get me coat... ing

A storage startup aiming to develop new approaches to cathode production for batteries is stepping out in the solar community for the first time. Enhanced Battery Solutions GmbH (EBSL) was spun out of industrial equipment manufacturer Von Ardenne and is taking part in The smarter E conference for the first time.

“EBSL was officially founded [in] October last year,” says managing director Andreas Purath. “This is the first time we’re engaging with the solar community, but there are also so many battery companies here, so we thought it was a good idea to place the message at [the Von Ardenne] booth.”

EBSL is developing a new coating to battery cathodes, which it calls XPrime. The coating delivers lower contact resistivity, facilitating higher current – in short, faster battery charge rates, EBSL says. XPrime could also facilitate batteries with higher cell voltages, such as solid state batteries – which are in an early stage of development.

“We are in the proof-of-concept phase, so we’re promoting the first result: the XPrime,” says Purath. “It is a layer that we coat on the current collector on the cathode side – [an] ultra thin, dense layer; compare it to a primer which is done by wet chemical approach but the big difference is cost wise – it’s much lower. No binder is used but it is a really dense layer.”

EBSL has a team six-strong team and says its goal is to address the “core challenges” facing the battery sector – charge rate, energy density and cost. And when it comes to the production tooling used to deposit Prime, Von Ardenne’s battery equipment team is ready to help. How convenient.

The prospects for bifacial

Our boss Gouras went on to chair a discussion about the bifacial market and other issues at the Longi launch, which included representatives of inverter maker Sungrow, tracker manufacturer Arctech and Dutch solar supplier Solarclarity.

Robert Jan Poot, procurement director for the latter, highlighted the growing popularity of bifacial modules, saying: “The Scandinavian market is pretty active. We hope there will be more field applications – maybe floating – but first of all let’s focus on our commercial applications. Most important for the Dutch market is stable supply and reliable partners, such as Longi.”

Perhaps not surprisingly, Shitao Wang, chief technology officer for Chinese manufacturer Arctech, wanted to stress selecting the correct module was only part of the solution when seeking to maximize energy output in solar projects. “Bifacial and [the] tracking system uses AI to improve energy yield,” he said, before stressing the importance of avoiding shading to the back side of bifacial installations.

High hopes

Wahl, from Longi’s German unit, has high hopes for bifacial as a technology, as well he might, having reiterated his parent company’s plans to become even bigger, in terms of production output.

“The global market is increasing,” he said, “to simply defend our market share we have to grow. Two years ago, everybody was asking ‘how can we deal with [bifacial]?’ But now there has already been 5 GW shipped and customers using them in [Central] America, North Africa and China have experienced advantages in tenders. Ten per cent more electricity from the back side, or even 15% when maximized: that gives you a competitive advantage. The market is ready, I wouldn’t be surprised to see 100% growth [this year] from bifacial, and the banks understand that.

“Bifacial starts at utility scale but my personal view is that it will end up on the rooftop. It comes first from utility [scale] but it will sooner or later come into other areas, car parks, whatever you like.”

There was, however, one crushing and very public injustice meted out at the Longi launch, as yours truly won the prize draw for an iPad but was forced to surrender the prize because I’m an employee.

Longi can prepare itself for some pretty negative coverage from now on, that’s all I’m saying.

pv mag takes the stage

pv magazine’s own Eckhart Gouras has just compered the launch of Longi Solar’s Hi-MO 4 high efficiency, half-cut, monocrystalline bifacial module at Intersolar.

Promising a 15% uplift in power output from the 375 W Hi-MO 3, the new module has a 420-430 W power rating, an efficiency of up to 22.5%, a 30-year lifespan and is available in bifacial or single-sided options as 2×60 or 2×72 layouts, as well as claiming to occupy 1.2% less land area than its predecessor.

Winfried Wahl, head of product management and chief engineer for Longi’s German operations walked a packed crowd through the history of the product, with the Hi-MO 2 the Chinese manufacturer’s first bifacial offering and version 3 a half-cut, bifacial mono PERC iteration.

There was even a nod to Stranger Things in the music booming out in accompaniment to a glossy corporate video of the module. What’s not to like?

Generators that don't drink diesel on the Galapagos Islands

Andreas Boes, business development LatAm Distributed Energy Systems, with Siemens is proud talking about his company's zero fossil fuels project on the Galapagos Islands.

Siemens deployed a PV system, in combination with energy storage devices and fuel fired generators. The clue: the generators don't drink diesel. Siemens fiddled with a diesel engine to develop a taste for plant oil. Local farmers grow the plants as an enclosure for the fields. The fruits, previously without a purpose for the island's inhabitants now step in when the PV system does not suffice.

“What makes me so happy is that the people on the island had been a little bit skeptical about the intermittency of renewable energy before. Now with the system running they are convinced of the security supply and see that outages have gone down significantly actually”.

With this project on the Galapagos Islands, Siemens has entered the Intersolar awards. Good luck, Andreas.

Anticipating the TOPCon wave

While cell production producers are few and far between in Europe, the region’s production equipment providers are readying for the next wave of cell line upgrades.

And after aluminium-oxide enabled PERC, what’s next? TOPCon, answer many. TOPCon refers to a PERC cell architecture, which passivates the cell contacts – Tunnel-Oxide Passivated Contacts, hence the name.

Meyer Burger is presenting a lab version of its CaIA PECVD tool at Intersolar, and reports that it has already supplied one of the tools to a customer in Asia. A full-scale production CaIA is expected to be released later this year. The Swiss supplier says that it allows for PERC cell lines deploying PECVD tools for AlOx passivation to upgrade to higher efficiency TOPCon

“There is huge capacity of PERC, that has been added to the industry in the past years,” said Adam Ge, Meyer Burger’s head of global sales. “PERC capacity [using AlOx ] could reach 110 GW by the end of this year, plus or minus 10 GW depending on who you talk to. TOPCon is an upgrade of this existing capacity to the next efficiency level.”

For the next step after PERC, Ge says that heterojunction is the obvious choice. “For greenfield [cell production[ people are more inclined towards HJT.” But, then again, the Swiss tool maker would say that.

Meyer Burger is participating in the launch of the new REC module at 4pm today (booth A2.380). The 60-cell module comes in at 380 Wp and deploys Meyer Burger’s HJT technology, along with its Smartwire cell interconnection. REC is targeting 600 MW of production of its new HJT module.

Bridging the gap towards BIPV

A renewed push to realise BIPV deployment is under way – aiming to break down the barriers between the solar sector, architects, planners and construction industry.

But you could be forgiven for thinking, building integrated PV, we’ve heard it all before and nothing has really happened, right?

“There are a lot of barriers [to BIPV deployment],” says Björn Rau from the Helmholtz Zentrum Berlin, who is leading an initiative that looks break down these barriers. “There are different mindsets, technical things and regulatory issues… on one side is the PV module manufacturers and research centres, working on module efficiencies, and the other hand investors, architects and planners who are afraid of new technical issues that can arise from BIPV.

“But they [architects and builders] are also not award of the possibilities, coloured modules, different surfaces, all these things. So we have formed a group of institutes, companies working in the [BIPV] field, to improve the business of the members of the alliance.”

The alliance Rau is speaking about is the Allianz Bauwerkintegrierte Photovoltaik, which has a stand in hall C4 at Intersolar, for the first time this year. But along with that, Rau is spearheading a publicly funded intitiative, for the next four years, that is also looking to foster dialogue between the PV and construction sectors.

Breaking down barriers. Build up with PV. That’s the message – more or less.

Selling modules, system and now power

While a press conference will set out its new power retail business in more detail tomorrow, we got a quick preview to Hanwha Q Cells’ new Q Energy and Q Home Cloud services.

Having already expanded its offering from modules to full PV and storage systems for residential customers in previous years, Q Cells is launching its electricity retailing program during Intersolar.

“People are first surprised and then enthusiastic,” said Madlen Apel, the team leader of Q Cells Systems Solutions unit. “We have completely changed the setup, from being the module provider to the complete energy provider. It’s quite new for our customer and Q Parters [installation partners], but quite well accepted already.”

Q Cells will first roll out its Q Energy and Q Home Cloud services in Germany, but plans to expand it into other markets. The company describes it as “closing the gap for the private end customer” by providing a “one stop shop, independent on whether you do or don’t have a solar system.”

Q Energy will come with two tariffs, one Basic tariff that doesn’t differ significantly from other clean electricity tariffs, and the Smart Tariff, which will involve the householder receiving a day ahead price forecast, allowing the homeowner to switch on or off electricity hungry appliances according to price.

Interestingly, households that don’t have a rooftop solar system installed, can still sign up for Q Energy.

Q Cells’ Apel says that the company has been working on the Q Energy offering since the start of this year. The Q Home Cloud will be available for households who have a Q Cells solar+storage system installed. It is expected to be released later this year.

Q Cells is also promoting its bifacial module at the show, which it says is now in “mass production”. The 395Wp Q. Peak Duo L-5.3/BF is a dual-glass module, that utilises 0.2mm glass – weighing in at only 18kg. Q Cells says it is currently being produced for an unnamed PV power plant project, with full commercial systems set to commence in 2020.

An engineering feet

For a couple of years now there has been discussion about how much weight to put on flat roof mounting systems to prevent them being blown away over the course of 20 or more years.

Just a week ago, Netherlands company Esdec launched a new east-west system and Jeron Weller, the physicist responsible for the company’s wind load model development, told pv magazine Esdec has invested years of research into the problem.

In addition to wind tunnel testing, says Weller, the company tested the stiffness of its system on a large surface area to discover how best to distribute ballast.

That ballast is required to keep solar rooftops in place but puts a strain on some buildings. For structures and arrays which require such a load, Esdec added an extra foot to its mounting system plus an additional weight tray, to limit the pressure the feet exercise on the roof in order to avoid limiting isolation.

You might call it putting your best foot forward.

“Where’s the masking tape!”

Correction: Longi will be launching its new module at 2pm and, in even better news, the cake has just arrived in the press center. It’s as though all my Christmases have come at once.

If the delayed launch is down to a technical hitch, the Longi staff can console themselves they are not the only ones. I popped into the nearby Yingli Solar stand, where I saw someone slapping masking tape on the back of module.

Hi-tech indeed.

Now for cake…

Germany on the upswing for local solar EPC

Pfalzsolar is a utility-owned EPC that is scaling in momentum as the German solar market turns up. The company is the official pv magazine live sponsor, and today caught up with us to discuss its business model, the European market, trends, and its special promotion to The smarter E exhibition attendees over the coming days.

Pfalzsolar services a variety of industry segments. Working with investors, commercial and utility scale, residential, and also operations and maintenance – can you talk about the range services that you offer to each of these customer groups?

We have three divisions. First, we have the project development business, including classical EPC and commercial roofs, with systems greater than 200kW. Then, O&M, a department with a portfolio that will reach over 300 MW this year. And then we have our residential basis, where we do installations 150 to 200 km around our headquarters location city.

It looks like a wide range of services, but in the end, everything is connected. For clients of our EPC services and project development, we offer them our O&M services – which is a technical benefit because there is in-planning direct feedback from the guys who will eventually be monitoring the systems. With the residential business, there are a lot of new developments, for example storage, with even more opportunity.

How does Pfalzsolar maintain specialization and excel in servicing such a wide range of clients and projects?

We are part of the 1,500 employee Pfalzwerke Group, the biggest utility in southwest Germany. We have a commitment to always perform to the utility standard. You will find experts in grid power trading and electrical services. We often have exchanges with them, and this helps us ensure high quality in our services. This is on the technical side, but nevertheless, what really best supports us is having a team that is in love with what they do. And as you may know, we have the slogan ‘We love solar’ and this is more than a slogan to us, it is a commitment toward our work.

Your company launched in 2003. What have been the biggest changes internally for the company since then, and what type of growth have you experienced since Pfalzsolar’s inception?

We started with 6 people and have now reached 55 employees and are still growing. For example, we moved into a new office and we even need to extend this. As our markets our getting more international, our team is getting more international. As we are growing, our project sizes are growing. Coming from 1, 2, 3, 4 megawatts to 15 and now even 50. Everything is getting bigger.

This week we are at Intersolar Europe. Pfalzsolar’s work is based in Germany, but what markets is the company currently focused on in Europe and globally?

Our company’s activities and developments are focused on the U.S., Germany, Spain, Portugal and the Netherlands. About 70% of our business is in the Netherlands. We believe that all these markets have a bright future. From just a mid-term outlook, we are concentrating on Europe and the U.S.

Are there any noteworthy projects or initiatives that Pfalzsolar is currently undertaking in Europe?

Our biggest project is 34-MW, which we are currently building in the Netherlands. It is the size of 55 football fields, and we have already passed half time. In addition, we recently won the contract to build a 21 MW solar park on site of the only nuclear power plant in the Netherlands. On our website www.welove.solar you can see some exciting updates on these as well as on our other projects during Intersolar. Beyond these, we are very happy to see that Germany is back, and back for us in 2020, as we won the auction. We see Germany uprising, even with bigger projects.

What do you see as the biggest market trends currently, and how is Pfalzsolar’s business engagement?

For development and EPC work, we see a strong growth on the project side, it’s scaling up. Mainly we see projects around 10MW in size, but we are discussing 20-50MW projects. This for us is one of the biggest challenges, as the demand gets larger, we already see that module manufacturers’ capacities are short.

How can individuals connect with Pfalzsolar here at Intersolar?

If you want to set up an appointment, go onto www.welove.solar to arrange an appointment with us. Or you can participate in our competition and win one of 2 e-scooters.

What’s occurin’?

I’m off for another wander to see what curious solar-related delights to bring you all later and I’ll be back live soon as the nice people at Longi are launching a new module at their stand in around 40 minutes’ time.

Yes, you read that right, the launch is at 1pm… haven’t these people heard of lunch?

An African ambition

Now we’re back into the swing of things, rocking up at press conferences too late to know who any of the speakers are and what the subject is – at least there were no owls present.

The German Ministry for Economic Cooperation and Development (BMZ) was presenting its People’s Green Energy program to drive off-grid solar installations and provide kit such as solar water pumps across Africa.

The ministry’s Bärbel Hohn made the point that encouraging renewable energy in parts of Africa with limited access to electricity would allow people to “skip coal” entirely.

“They can be digital all of a sudden, and they have pay-as-you-go. Many Germans are dreaming of this technology here [in Germany],” she said.

A step change

Responding to a question from a visitor who said the program was creditable but had to be much larger she replied: “There is an African proverb that says: ‘if many small people take many small steps, you can change the world’.”

And before the wags among you start asking what people’s height has to do with anything, bear in mind this is the live English translation of a German official’s rendering of an African saying.

The prize for the most Larry David-esque choice of metaphor, however, must go to Hohn’s colleague Ingolf Dietrich, who attempted to chart the changing mindset as renewables become the norm by comparing it to the debate over slavery, progressing as it did from a situation where slavery was not seen as problematic to one where people could not imagine it had ever been acceptable.

That’s one way of looking at it, I suppose.

A tunnel vision

I’ve been having a wander around the module and cell manufacturers’ hall and encountering more modules than you can shake a stick at.

There are numerous big names here with a heavy Chinese presence but it’s Korean manufacturer QCells that owns the space in Hall A, with a huge structure that dominates upon entry.

The displays range from vast, glossy stands decked with panels to hastily tacked up cubicles with banners attached to the walls by unfamiliar brands.

And there is a varied mix, too, in approaches. Avancis, the German module developer of Chinese parent CNBM (China National Building Materials) lets the tech do the work with its impressive display section of the Dragon’s Neck, a public walkway planned for Shanghai that will covered in 140 W CIGS thin film modules.

Other brands, though, have failed to take heed of the #MeToo movement and persist in asking models to dress in ridiculous outfits for baffling reasons. Step forward QCells – it doesn’t matter how big your display is, you still need to show some class.

A changing of the guard?

As the number of visitors starts to swell at the turnstiles of Messe München, Johannes Bernreuter has written an article for pv magazine about how the solar markets of Europe and the Middle East are fast gaining ground on China.

You can read all about it

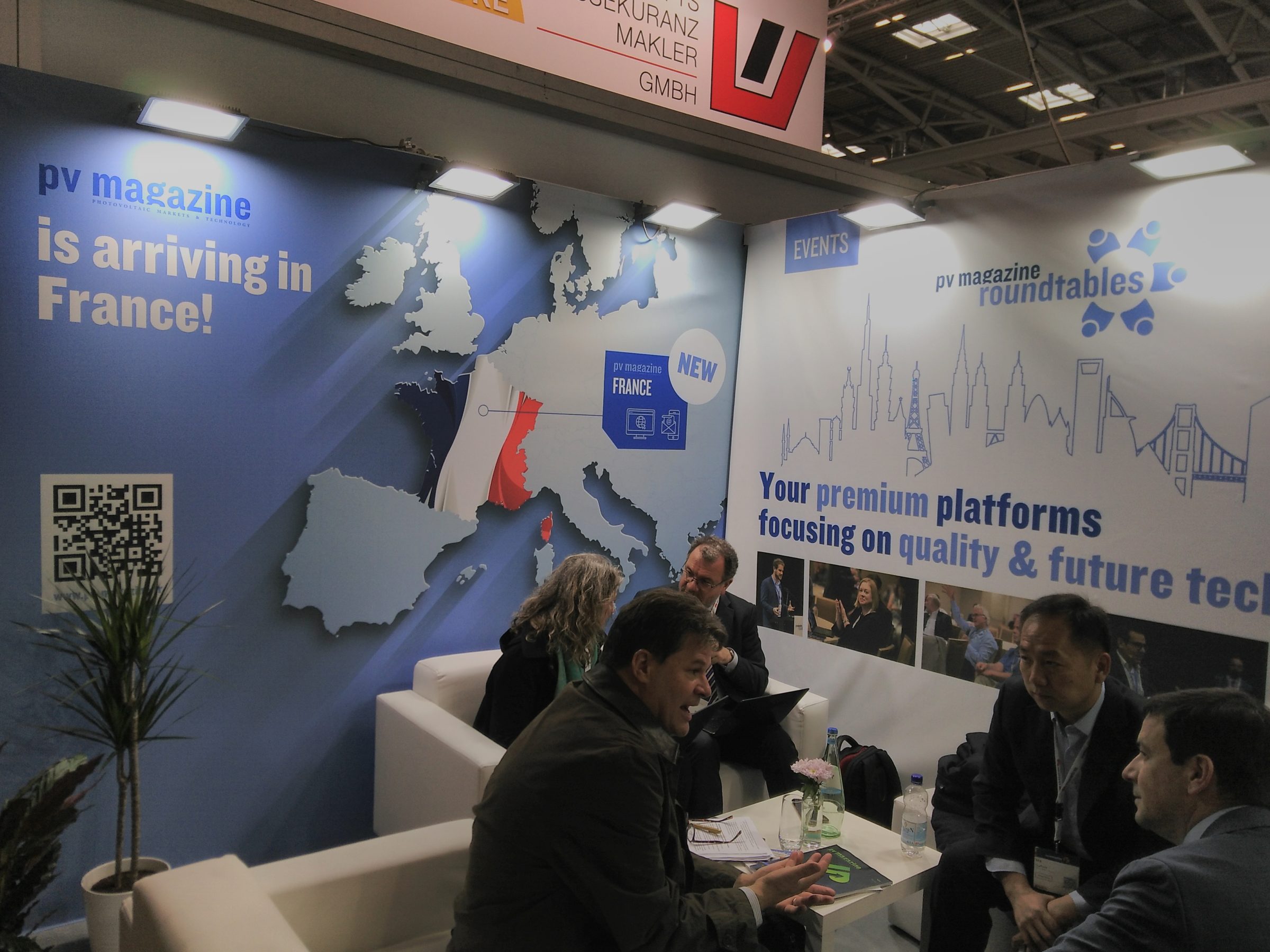

Bonjour solaire !

Say Bonjour to pv magazine France the latest edition to the pv magazine Group family! From today, editor Catherine Rollet will be reporting on the latest solar and storage news, technological trends and market developments in French language. If you’d like to find out more, email Catherine.rollet@pv-magazine.com Or visit stand A2.540. We will also be partnering with We will also be partnering with the French-German office for ecological transition (DFBEW/OFATE) at Intersolar for their event, Ground-mounted Solar PV Systems in France and Germany: Land Use and Business Models on Thursday, May 16, from 15-17 in Hall A3, Room A32.

Mornin’ all

Good mornin’ folks,

I’ve managed to fight the crowds on the U-bahn and found the venue after a brief detour around a nondescript nearby industrial estate and, having grappled with the truculent wifi, am finally ready to get going.

Welcome to Intersolar Europe 2019, I'll be blundering around finding out about Europe’s mooted ‘solar renaissance’, whether the burgeoning trade stand off between the U.S. and China will lead us into a world resembling the Pandemic Legacy boardgame and, most importantly, trying to find out why there’s a giant owl wandering around the conference.

Now I’m off to see just what the story is behind the ludicrously dressed staff at the Hanwha Q Cells stand.

Back soon.

The #UPrising

It is Day 1 of Intersolar Europe and pv magazine is excited to announce the launch of our new sustainability campaign, UP! Over the coming weeks, months, and years we will be diving deep into the topic of what it means to be truly sustainable.

Indeed, at this point it is undeniable: Solar PV and energy storage together are an unstoppable force; an essential ingredient for the much needed clean energy transition. However, with great power comes great responsibility.

One of the most pressing issues for the industry in the coming years is that of end of life, yet few countries have adopted PV-specific waste regulations. Sustainability issues around the mining of conflict materials such as cobalt for batteries, and the handling of chemicals like hydrofluoric acid in production processes, are also concerns that need to be closely examined.

Read about how you can join UP, step UP and help us shape the sustainability agenda in the May edition of pv magazine. You can also find out more information in person at the Future Roundtable event between 13.30 and 14.30 and at the Quality Roundtable event between 17 and 18, both on Thursday in the ICM Conference Center, Room 5. Alternatively, visit stand A2.540 and ask for Becky, connect with us on Twitter via #UPrising, or email up@pv-magazine.com

Win an electric scooter from Pfalzsolar

The official pv magazine live sponsor, Pfalzsolar, is running an exciting giveaway for exhibition attendees of The smarter E 2019. Visit www.welove.solar now to register to win one of two all-electric scooters.