Researchers from the Institut Photovoltaïque d’Île-de-France (IPVF), in France, have developed a mini perovskite solar module by using chemical bath deposition (CBD) for the deposition of the solar cell's electron layer, which is based on tin oxide (SnO2).

Through CBD, a large number of substrates can be coated in a single run with a proper chemical bath design. “CBD is an inexpensive deposition method that can produce highly homogeneous layers on large areas at low temperatures,” the scientists explained. “CBD has previously been employed at the industrial scale to produce cadmium sulfide (CdS) and zinc sulfide (ZnS) buffer layers in CIGS photovoltaic modules.” The deposition process was performed for a hour and the temperature of the CBD reactor was maintained stable at 70 degrees Celsius. “The desired SnO2 thickness was achieved by repeating the CBD deposition process multiple times. Finally, the substrates were rinsed with water and annealed at 180 degrees Celsius for one hour,” the research group stated.

The solar cell was fabricated with a glass-coated substrate made of fluorine-doped tin oxide (FTO), the SnO2 layer, a film made of a perovskite known as CsI/PbI that was deposited via slot-die coating, a spiro-OMeTAD hole-blocking layer, and a gold (Au) metal contact. “This two-step deposition process, previously developed in our laboratory, allows the deposition of uniform and pinhole-free perovskite layers,” the academics said, referring to the slot-die technique used. “During the process, an intermediate layer containing CsI and PbI2 is deposited by a first slot-die coating step, then vacuum-treated to remove excess solvent and thereafter converted to perovskite [by] applying the organic cations solution on top using a second slot-die coating step.”

Popular content

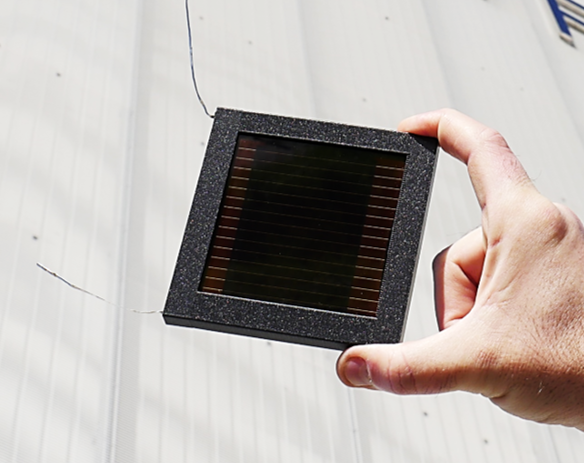

The module was built with 19.2%-efficient perovskite cells that were connected in series through laser ablation with P1, P2, and P3 scribing steps. The champion panel, with an aperture area of 40cm2, achieved a power conversion efficiency of 17%, an open-circuit voltage of 17.61V, a short-circuit current of 1.3mA/cm2, and a fill factor of 73.5%. “We believe that the relatively small drop in efficiency from small cells to 40cm2 modules is due to the homogeneous deposition of the SnO2 layer and of the perovskite layer, due to the use of [a] scalable technique,” the researchers concluded.

The mini perovskite module is introduced in the paper “Industrially Compatible Fabrication Process of Perovskite-Based Mini-Modules Coupling Sequential Slot-Die Coating and Chemical Bath Deposition”, published in ACS Applied Materials & Interfaces.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.