Scientists at the Mahidol University in Thailand have developed triple-cation perovskite solar cells for low-light applications using a manufacturing process based on antisolvent deposition and vacuum thermal annealing (VTA).

“VTA leads to compact, dense, and hard morphology while suppressing trap states at surfaces and grain boundaries, which are key culprits for exciton losses,” they stated, emphasizing the importance of the second step to produce a high quality perovskite layer. “As indoor light intensity is at least 300 times lower than that of sunlight, dense and homogeneous perovskite formation enticed by vacuum thermal annealing is valuable.”

The researchers implemented the process via a vacuum flask connected to a vacuum pump with controllable pressure and located on top of a hotplate to regulate the temperature. They used a perovskite material known as FA0.45MA0.49Cs0.06Pb(I0.62Br0.32Cl0.06)3 treated with bromide and chloride. After the treatment, its energy bandgap was 1.80 eV.

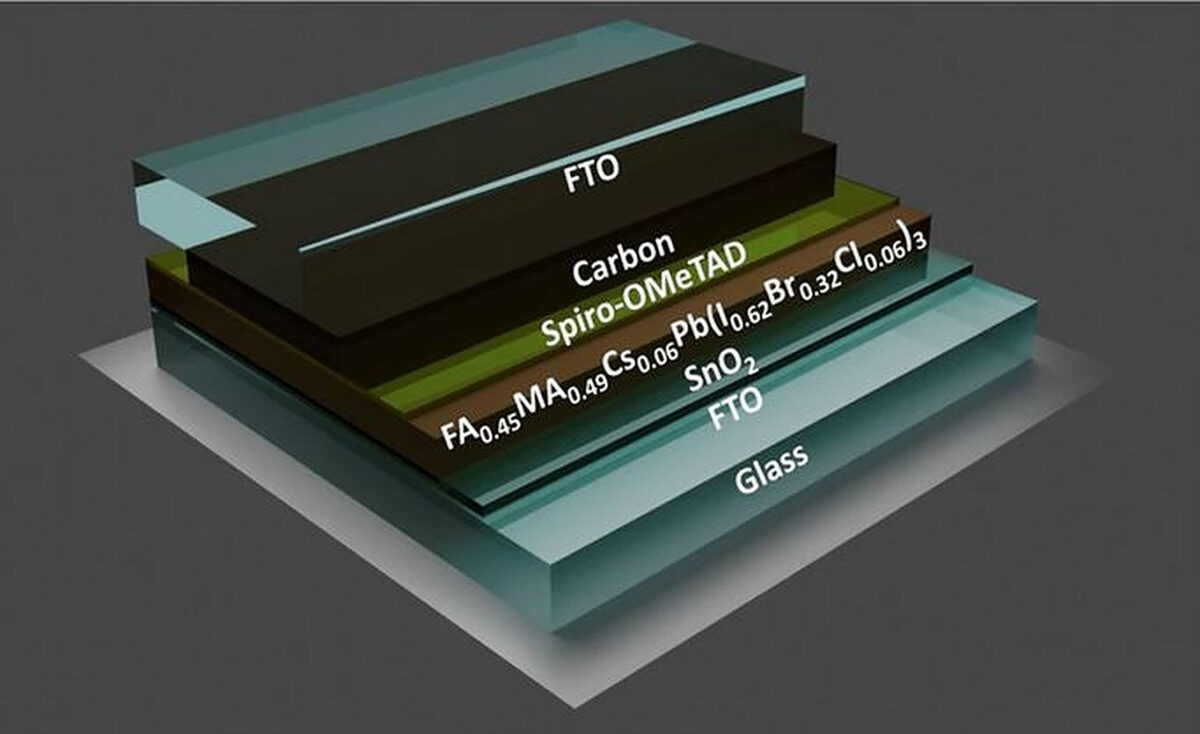

They built the cell with a substrate made of fluorine-doped tin oxide (FTO), an electron transport layer (ETL) based on tin(IV) oxide (SnO2), the perovskite absorber, a hole transporting layer (HTL) made of Spiro-OMeTAD, a carbon top electrode, and another FTO layer. The device has an active area of 0.04 cm2.

Popular content

Tested under indoor light at 1000 lux, the cell showed a power conversion efficiency of 27.7%, an open-circuit voltage of 0.93 V, and a short-circuit current of 0.16 mA/cm2, with peak efficiency reaching up to 32.0%. A reference device without VTA treatment achieved an efficiency of 25.5%, an open-circuit voltage of 0.91 V, and a short-circuit current of of 0.16 mA/cm2, with peak efficiency reaching 30.7%.

pv magazine print edition

In the latest issue of pv magazine we turn the spotlight onto European solar with a comprehensive review of the state of the PV industry across the region’s key markets and a look at the legislation which aims to drive a solar rooftop boom. We also examine the difficulty of establishing a solar panel recycling industry in Australia, where industry backbiting isn’t helping matters.

“VTA leads to reduced surface roughness and electronic traps both at the bulk and the surface,” the group said referring to the superior performance of the VTA-based cell. “VTA opens doors for robust perovskite formation and could practically be adapted for various perovskite compositions towards desirable optoelectronic applications for modern society.”

The solar cell is introduced in the study “Robust perovskite formation via vacuum thermal annealing for indoor perovskite solar cells,” published in Scientific Reports.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.