Researchers at the Universiti Kebangsaan Malaysia have designed a bifacial photovoltaic-thermal (PVT) panel that utilizes circular jets impinging as a cooling medium.

“We have fabricated a prototype for lab-scale purposes,” the research's corresponding author, Adnan Ibrahim, told pv magazine. “However, the proposed cooling technique, called reversed circular flow jet impingement (RCFJI), could be implemented in real applications according to the module sizes used by the user.”

The system consists of a reversed circular flow cup placed at a distance of 25 mm below the back of a jet plate with 36 jet plate holes, each measuring 3 mm in diameter. The air enters the air inlet, circulates through the RCFJI cup, and leaves then the jet plate with high velocity, causing impinging effects on the bifacial module.

“The impinging effects enhance the heat transfer rate, thus cooling down the bifacial module temperature and enhancing the photovoltaic efficiency,” Ibrahim said. “In addition, the air outlet is converted into thermal energy.”

The reversed circular flow jet impingement was fabricated through a 3D printing process using polylactic acid filament, which the scientists said eased fabrication and cost. “The polylactic acid filament can withstand temperatures up to 110 C while the PVT collector does not exceed 60 C,” Ibrahim added.

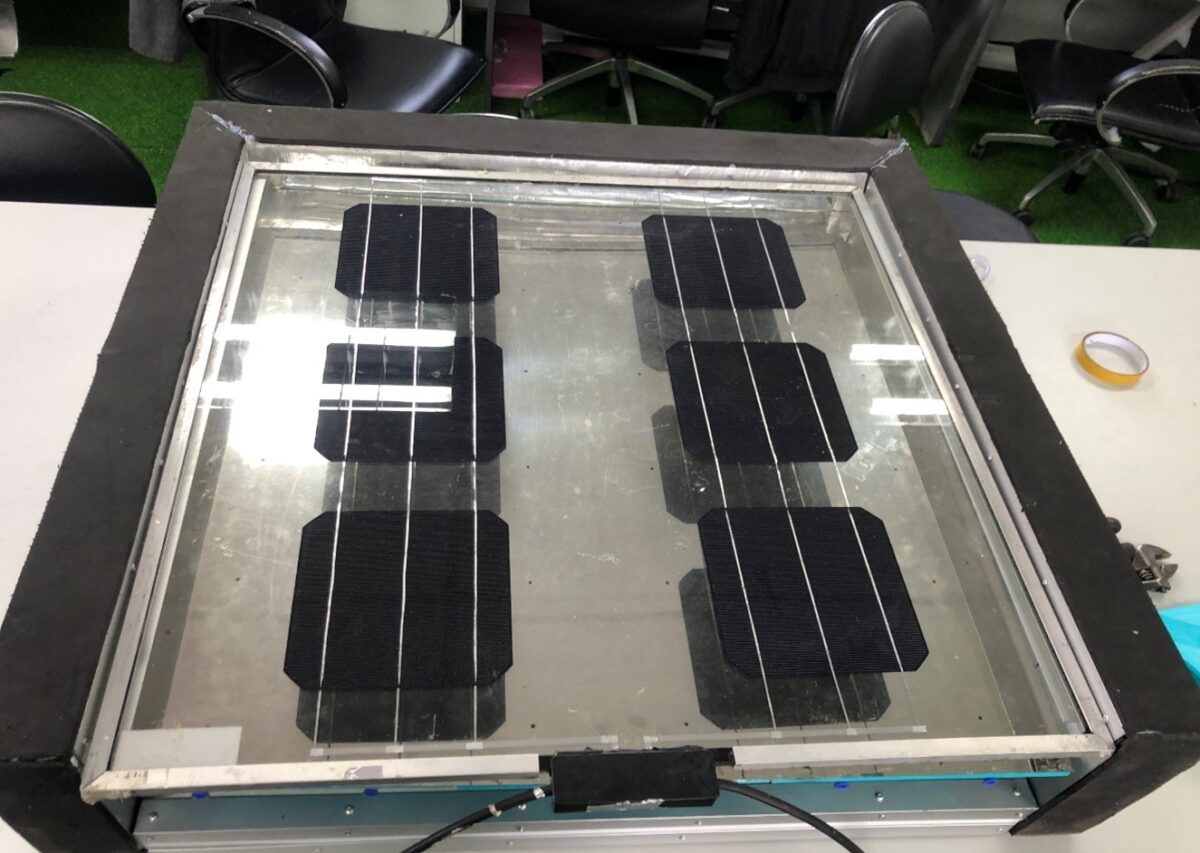

The PV panel has a size of 698 mm x 619 mm and uses 12 monocrystalline solar cells with dimensions of 156 mm x 156 mm. It has a nominal power of 60 W, an open-circuit voltage of 22.12 V, and a short-circuit current of 3.71 A.

The researchers tested the PVT panel under different solar irradiance between 500 W/m2 and 900 W/m2. They found the collector achieved the highest photovoltaic exergy of 47.2 W at 900 W/m2, while the lowest of 28.1 W was reached at 500 W/m2. “Across the range of 500–900W/m2, the photovoltaic exergy values were determined to be between 24.88 and 27.18W, 29.45–32.34W, 33.89–37.40W, and 38.20–47.27W, respectively,” they explained.

Popular content

They also observed that the panel's exergy efficiency reached a peak value of 12.64% when subjected to 900 W/m2, while the lowest exergy efficiency recorded was 12.25% under 500 W/m2. “In addition, the optimal operational mass flow rate was determined to be at 0.06 kg/s based on the exergy efficiency,” they added.

According to Ibrahim, the proposed PVT solar collector has a cost-benefit ratio of $0.33/m2/kWh with a payback period of 1.5 years for a single device with an annual energy gain (AEG) of 2465.70 kWh/year. “The RCFJI bifacial module has great potential to be adopted commercially, mainly for off-grid system purposes,” he stated. “It is best suited for solar applications in remote areas, rural areas, and agriculture. For instance, its thermal energy could be used for drying purposes.”

The group presented the system in the study “Exergy performance of a reversed circular flow jet impingement bifacial photovoltaic thermal (PVT) solar collector,” published in Case Studies in Thermal Engineering.

Other researchers at the Universiti Kebangsaan Malaysia recently developed a photovoltaic-thermal system based on PCM cooling, multi-level fin heat sinks for solar module cooling, and passive technology for solar module cooling based on fin heat sinks.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.