Researchers from the East China University of Science and Technology have developed a new manufacturing process to fabricate printable mesoscopic perovskite solar cells (p-MPSCs). They claim that the new technique is able to overcome the typical challenges posed by this cell technology, namely their interfacial passivation and layered assembly.

Mesoscopic PV devices are commonly produced with an absorber layer that can be conducted by a solution-based approach and non-vacuum processing, which makes their production costs relatively lower than those of conventional solar cells. Using organic-inorganic layer structured perovskites has recently enabled scientists across to world to reach efficiencies of over 10%.

“We have replaced expensive metals with carbon materials as counter electrodes and utilized screen printing techniques instead of vapor deposition,” the research's lead author, Wenjun Wu, told pv magazine. “This not only reduces the manufacturing cost but also provides a more convenient coating process.”

The scientists utilized two thiophene-based molecules known as thiophene [3,2-b] thiophene (TT) and 2,5-dibromothiophene [3,2-b] thiophene (TT-2Br) as passivation agents for the grain boundaries in p-MPSCs. “This configuration allowed for the creation of a cross-interface bidentate passivation molecule,” Wu explained. “By exploiting the selective matching of the molecular lattice, we achieved efficient chelation with under-coordinated lead ions, thereby bridging crystal boundaries and improving charge transport.”

The chelation strategy modulated the strain of the crystal lattice of perovskite films, which resulted in an improved power output and voltage for the overall PV device.

In order to address the limitation of non-layered assembly caused by the carbon electrode's full light absorption in p-MPSCs, the scientists employed an artificial reflector device, which they claim allows for dual-sided four-terminal tandem assembly, with TT-2Br serving as the small molecule interfacial passivating agent.

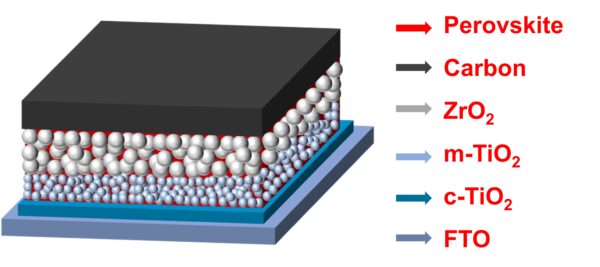

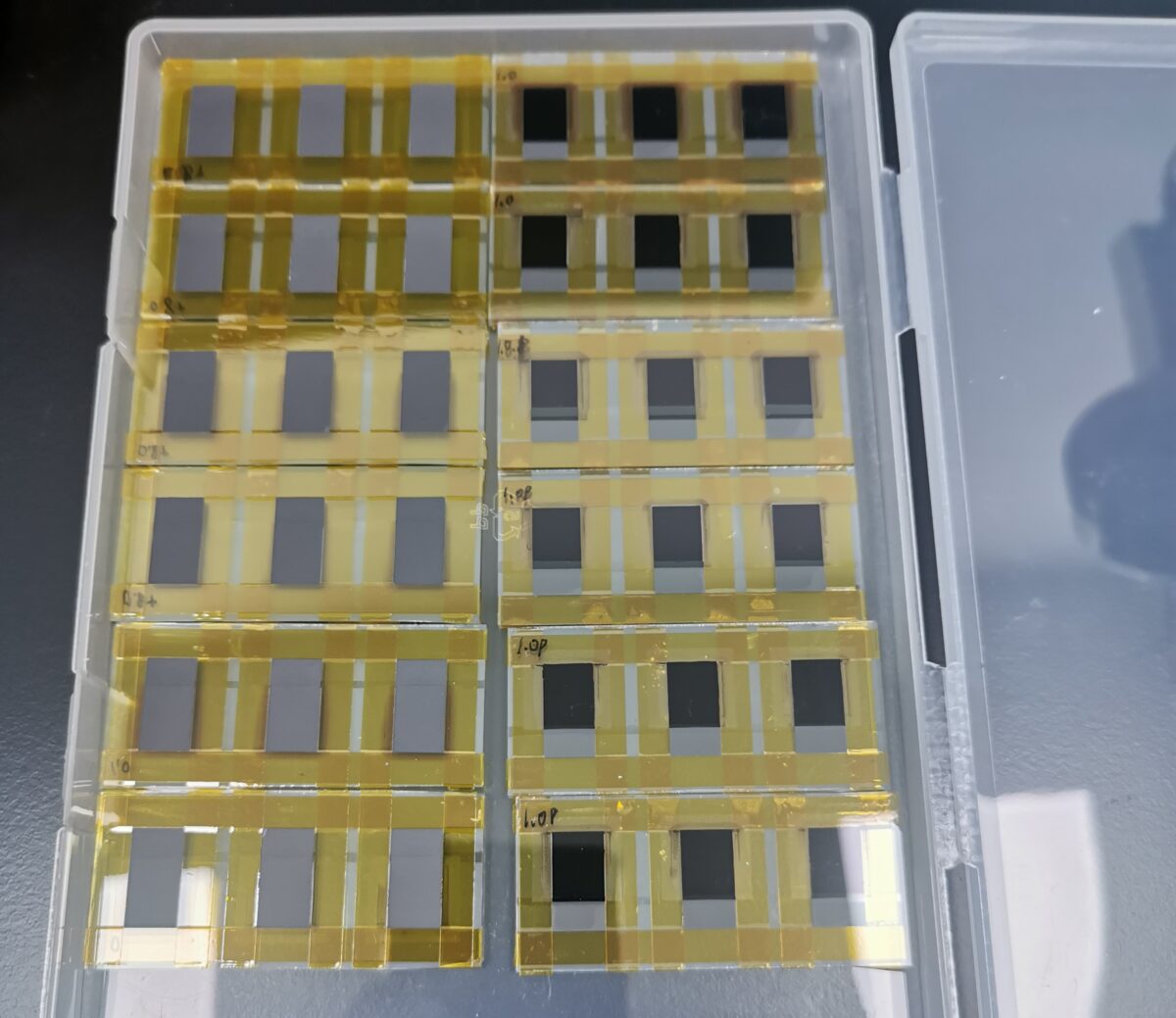

Image: East China University of Science and Technology

The Chinese group built the cell with a substrate made of fluorine-doped tin oxide (FTO), an electron transport layer (ETL) based on carbon–titanium dioxide (C/TiO2), a photocatalyst containing mesoporous titanium dioxide (m-TiO2), a zirconium dioxide (ZrO2) interlayer, a carbon electrode, and the perovskite absorber.

Tested under standard illumination conditions, the device achieved a power conversion efficiency of 17.48%, an open-circuit voltage of 1.01 V, a short-circuit density of 22.92 mA cm-2, and a fill factor of 75.33%. “Our innovative strategy also significantly improved the bifacial power output (BPO) to 20.44 mW cm-2 and the open-circuit voltage (VOC) to 2.03 V in series-connected devices,” Wu said. “In parallel-connected devices, the BPO increased to 25.84 mW cm-2, and the short-circuit current reached 39.96 mA cm-2.”

The solar cell was described in the study “Lattice‐Selective Cross‐Interface Bidentate Passivation for Efficient Bifacial Tandem Carbon‐based Perovskite Solar Cells – Shao – Solar RRL – Wiley Online Library,” published in RRL Solar. “Our approach opens up new possibilities for high-efficiency passivation and efficient assembly of photovoltaic devices in p-MPSCs, offering potential applications in practical usage,” Wu said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.