A group of researchers led by the Autonomous University of Querétaro in Mexico have proposed for the first time to fabricate thin-film solar cells relying on an absorber made of silver, barium, titanium, and selenium (Ag2BaTiSe4).

The scientists explained that their approach consisted of analyzing the absorber's electron affinity, interfacial defects, and parasitic resistance, as well as assessing the impact of these factors on cell performance. They also tested different types of buffer layers in the proposed cell configuration, in an effort to find non-toxic alternatives to cadmium sulfide (CdS).

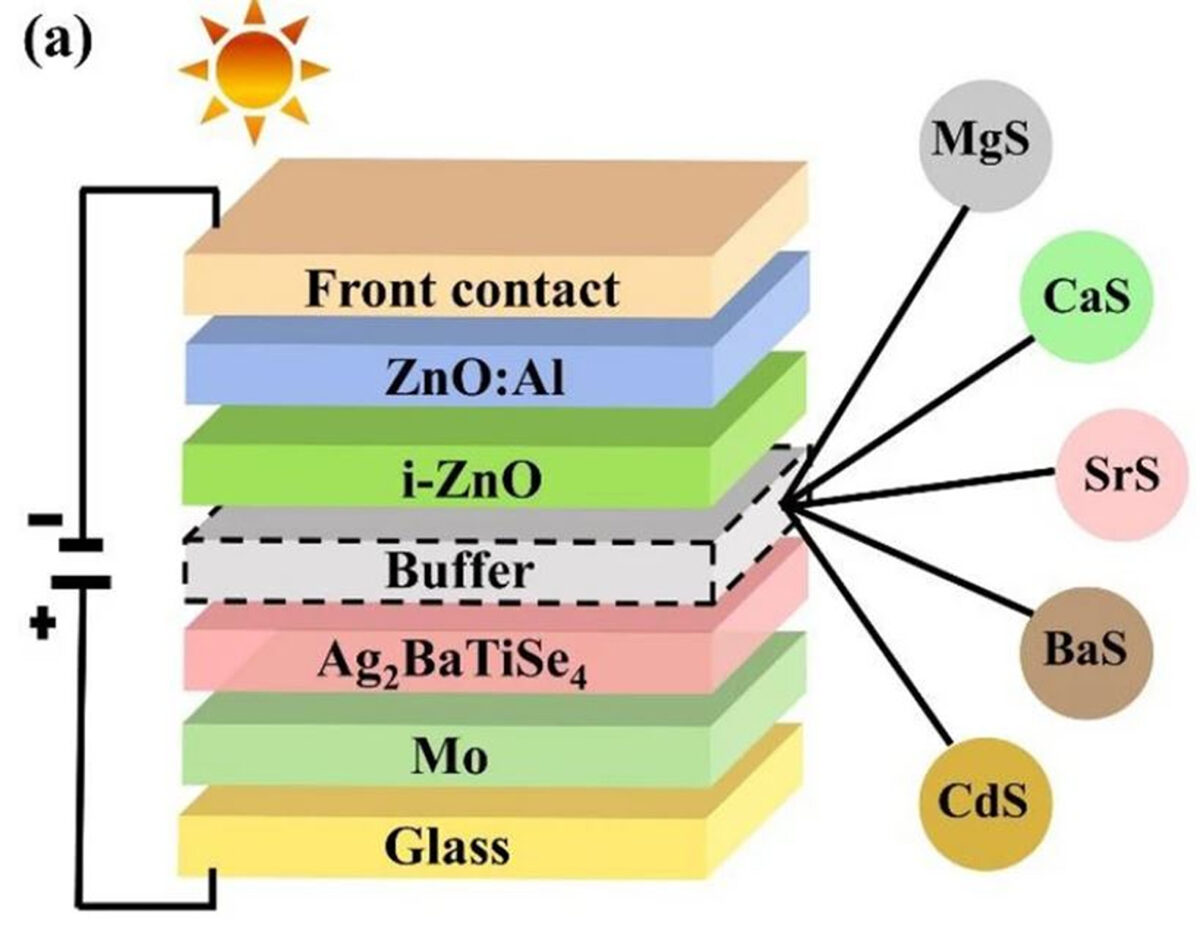

The research group used the SCAPS-1D solar cell capacitance software, developed by the University of Ghent, to simulate the novel cell design. The latter includes a glass substrate coated with molybdenum (Mo), a molybdenum diselenide (MoSe2) layer, the Ag2BaTiSe4 absorber, the buffer layer, and transparent conductive oxide films made of indium zinc oxide (IZO) and aluminum-doped zinc oxide (AZO), and a metal contact.

For the buffer layers, they considered using CdS as well as new alkaline earth metal chalcogenides such as magnesium sulfide (MgS), calcium sulfide (CaS), strontium sulfide (SrS), and barium sulfide (BaS). They took into account critical parameters such as thickness, carrier concentration, and defect density.

The team also introduced neutral defects at the Ag2BaTiSe4/MoSe2 and buffer/Ag2BaTiSe4 to create realistic operating conditions for the simulation and sought to assess how the buffer layers' carrier concentration influences the interface properties between the absorber and buffer in the cell. It also applied impedance spectroscopy to investigate the accumulation of charge carriers at the cell interface.

The researchers' analysis showed that the optimal value for MoSe2’s carrier concentration of 10 cm−3 and that of the thickness of the Ag2BaTiSe4 absorber should be between 0.5 µm and 1.6 µm. It also showed the solar cell may achieve a power conversion efficiency of 18.84% with a MgS layer, of 17.17% with a CaS layer, of 20.65% with a SrS layer, of 20.87% with a BaS layer, and of 18.66% with a conventional CdS layer.

Popular content

Further analysis demonstrated that, by finetuning MoSe2 parameters and interfacial properties, the efficiencies may reach 28%, 30.02%, 29.87%, 30.23%, and 29.68%, respectively.

The scientists concluded by saying that interface defects have a “massive” impact on the performance of the proposed cell design. “These defects are generally produced due to the structural defects between different layers and metal cation diffusion through the absorber during fabrication,” they explained. Thus, effective techniques must be employed for the deposition of layers, and methods such as etching, post-heat treatment, and inserting a passivation layer can be used to minimize the interface defects.

Their findings can be found in the study “Highly efficient emerging Ag2BaTiSe4 solar cells using a new class of alkaline earth metal-based chalcogenide buffers alternative to CdS,” published in scientific reports. “This work could open constructive research avenues for the photovoltaic community to fabricate highly efficient thin-film solar cells using novel Ag2BaTiSe4 as an absorber and new alkaline earth metal chalcogenides as alternative, non-toxic buffers,” they stated.

The team also included academics from the Bangladesh Atomic Energy Commission.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.