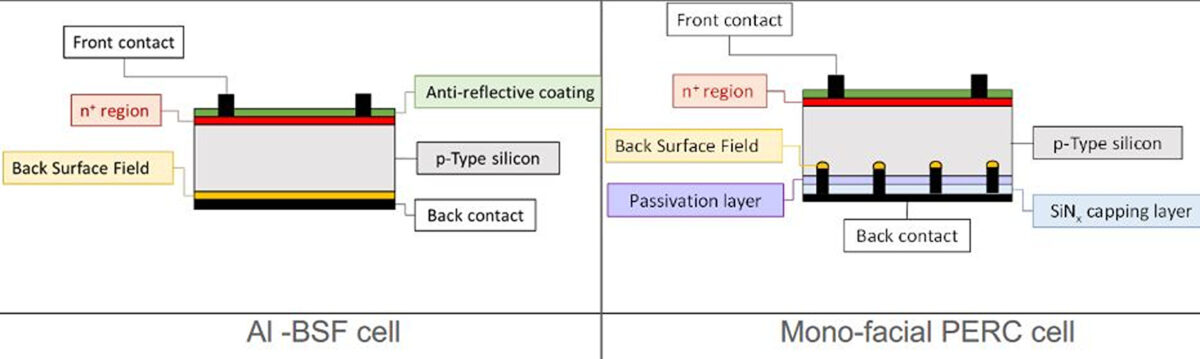

In 2022, the global solar photovoltaic (PV) generation experienced an unprecedented surge, marking a record increase of 270 TWh and reaching nearly 1 200 TWh worldwide. This remarkable growth underscores the pivotal role of solar energy in meeting the escalating global electricity demand while simultaneously mitigating greenhouse gas emissions. The driving force behind this was the establishment of new manufacturing capacities, alongside the transition from aluminum-back surface field (Al-BSF) cell technology to the more advanced passivated emitter and rear cell (PERC) technology around 10 years ago. The emergence of PERC as the standard technology is marked by its distinguishing features: an additional dielectric passivation stack on the rear of the cell and its possible bifaciality. This technology has replaced older cell structures like Al-BSF, primarily due to its improved efficiency gains in both PV cells and modules, leading to an increase in the nameplate power of modules. Moreover, there has been a notable rise in the adoption of Horizontal Single Axis Tracker systems, which offer higher kWh production per kW installed compared to fixed-tilt systems across various geographical locations. This shift towards more efficient and productive PV systems underscores a commitment to sustainable energy solutions.

Environmental Impact Assessment

While the energy production aspects of PV technologies have been extensively studied, a comprehensive understanding of their environmental footprint is essential. IEA PVPS Task 12 Experts have been employing their life cycle assessment (LCA) methodology to evaluate the environmental impacts associated with PERC technology in comparison to AI-BSF technology. By utilizing primary data from an Italian manufacturer, the report “Environmental Life Cycle Assessment of Passivated Emitter and Rear Contact (PERC) Photovoltaic Module Technology” provides an in-depth analysis of the complete life cycle of PV systems, encompassing manufacturing, installation, operation, and end-of-life phases. While based on analysis of data from only one manufacturer, the findings suggest that the transition from Al-BSF to PERC technology results in significant reductions in greenhouse gas emissions, energy consumption, and resource depletion throughout the life cycle of PV systems.

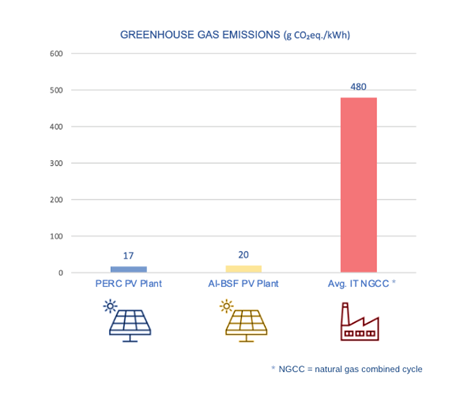

“The main thrust of our report is to analyze the impacts of the dominant technology in photovoltaics, using the LCA methodology and incorporating primary and up-to-date data,” Pierpaolo Girardi, co-Author of the report said. “This approach allows us to assert that electricity generated by PERC technology manufactured by an Italian company has a carbon footprint lower by 15% compared to electricity production with the currently most installed photovoltaic technology (Al BSF), and a 96% reduction compared to electricity produced by a typical Italian natural gas combined cycle power plant.”

Life Cycle Assessment Methodology

LCA is a structured, comprehensive method of quantifying material- and energy-flows and their associated emissions caused in the life cycle of goods and services. The ISO 14040 and 14044 standards provide the framework for LCA. IEA PVPS Task 12 subsequently developed guidelines, now in their 4th edition, to provide guidance on assuring consistency, balance, and quality to enhance the credibility and reliability of the results from LCAs on photovoltaic (PV) electricity generation systems.

Unveiling the Environmental Footprint

In their report, the Task 12 experts analyze two possible designs: (1) modules mounted on a horizontal single-axis tracker and (2) modules installed on a fixed structure. In addition, two possible PV locations with different irradiance levels are considered: one in the north of Italy and the other in the south of Italy; results shown here represent those for Southern Italy. The results, based on primary data from one manufacturer, are impressive:

- Greenhouse Gas Emissions: Transitioning from Al-BSF to PERC technology can lead to a reduction in greenhouse gas emissions per kWh produced across both locations. The additional passivation layer in PERC cells enhances energy conversion efficiency, thereby reducing the carbon intensity of electricity generation. Furthermore, the adoption of single-axis solar tracker systems amplifies this environmental benefit, as the increased energy yield per kW installed translates into lower emissions per unit of electricity produced.

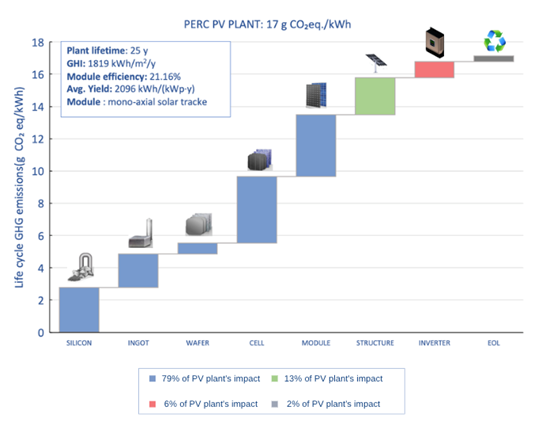

The new IEA PVPS Task 12 report analyzes in detail the greenhouse gas emissions associated with using the PERC technology (see Fig. 1 for an example)

Image: IEA-PVPS

The PERC PV plant located in the south of Italy is responsible for 17 g of CO2 equivalent per kWh produced. This figure illustrates the contribution analysis of the PERC PV plant based on primary data from an Italian PERC manufacturer. The percentages represent the contribution associated with each component/process. Note also that the tracking system is based on primary data from a manufacturer. The process/component highlighted in blue is associated with module production, which – from raw material to module assembly – accounts for 79% of the total life cycle of the plant.

When comparing the PERC PV plant to a typical Italian natural gas power plant (which accounts for about 50% of the Italian energy mix), the significant difference in greenhouse gas emissions becomes obvious (see Fig. 2). The comparison is made in terms of grams of CO2 equivalent emitted per kWh produced by each plant.

Popular content

Figure 2: Comparison of greenhouse gas emissions between different types of plants

Image: Cavalho et al., 2022

- Energy Consumption: Similarly, the shift to PERC technology is accompanied by a notable decrease in total energy consumption throughout the life cycle of PV systems. Improved cell efficiency and manufacturing processes contribute to this reduction, underscoring the importance of technological innovation in driving sustainability gains. Moreover, horizontal single-axis tracker systems exhibit higher energy yields per unit of land area, further optimizing energy production and minimizing energy consumption per kWh generated. Note also that the LCA of the tracking system is based on primary data from a manufacturer.

- Resource Depletion: While both Al-BSF and PERC technologies rely on a similar suite of materials, the efficiency improvements associated with PERC cells mitigate resource depletion impacts. By maximizing energy output per unit of material input, PERC technology minimizes the extraction and utilization of finite resources, thereby alleviating pressure on critical minerals and metals.

Paving the Path to Sustainable Solar Energy

The study highlights the potential environmental benefits of PERC technology. Based on the results of this case study of one PERC manufacturer, by utilizing PERC, the solar industry can reduce greenhouse gas emissions, energy consumption, and resource depletion, while simultaneously increasing energy yields. Additionally, the analysis of different mounting systems reveals that modules mounted on a horizontal single-axis tracker can lead to preferable environmental outcomes, especially in latitudes similar to those in Italy. Furthermore, a sensitivity analysis included in the Task 12 report suggests that extending the lifetime of PV panels can lower specific environmental impacts per kWh, emphasizing the importance of longevity in panel performance.

Moving forward, concerted efforts to promote the adoption of environmentally responsible technologies and optimize site selection can increase the realization of the full potential of solar energy as a cornerstone of the clean energy transition.

Download the full report here.

For more information on IEA PVPS Task 12 and Sustainability of PV Systems please click here.

This article is part of a monthly column by the IEA PVPS programme. It was contributed by IEA PVPS Task 12 – PV Sustainability.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

5 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.