Scientists from the University of New South Wales (UNSW) in Australia claim to have identified three new types of TOPCon solar module failures that were never detected in PERC panels.

“The results were quite surprising to us,” the research's lead author, Bram Hoex, told pv magazine. “We expected polyolefin elastomer (POE) in general to perform well, but we identified that some POEs performed very poorly. This is likely due to the different additives used in the POE which react with the soldering flux and the metallization resulting in contact corrosion.”

The scientists said their work was initially intended to assess the impact of bills of materials (BOM) on the reliability of both commercially available PERC and TOPCon solar cells. They specified that all modules were encapsulated at a pilot line within an unspecified industrial facility.

“These processes included soldering to connect ribbon and tabbing wires to the busbars and laminating to join BOM forming modules,” they explained, noting that all panels went through damp heat (DH) test at 85 C and 85 % relative humidity for up to 1,000 h. They said that all BOM components, such as glass, polymer backsheet, ethylene vinyl acetate (EVA), and POE, were procured from various manufacturers worldwide and were considered for high-volume manufacturing. The names of the suppliers were not disclosed, due to “confidentiality concerns.”

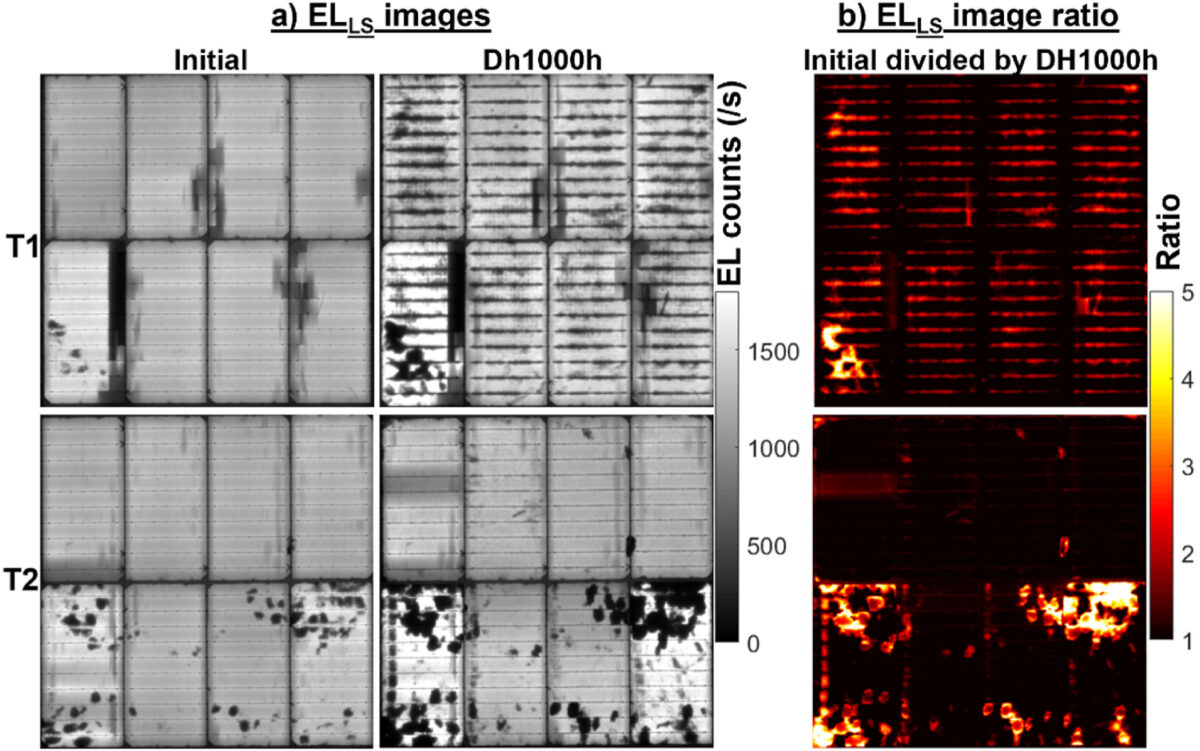

The team conducted current-voltage (I–V) measurements using an Eternalsun Spire module flash tester and captured Line-scan open circuit photoluminescence (PLLS) and electroluminescence (ELLS) images via a BTi-M1 luminescence line-scan system before and after the DH test. “ELLS image ratios were obtained by dividing ELLS images captured before and after 1000 h of DH testing using Lumitools, an advanced image processing software,” it emphasized.

The series of tests showed that the methods used to encapsulate the panels with high-quality (POE) and lower-quality (EVA) had a “negligible” impact on the performance and reliability of the PERC cells, with the observed alterations being defined as “minimal in nature.”

By contrast, the tested TOPCon cells showed higher maximum power loss compared to their PERC counterparts, with maximum power values decreasing from around 30% to 25 values for modules encapsulated with different types of POE and from approximately 29% to 26% for panels encapsulated with EVA. These losses were mainly attributable to an increase in series resistance.

“Our findings indicate that PERC modules demonstrate stability, with only a 1–2% decrease in maximum power after 1000 h of DH testing, irrespective of the BOM used,” the research group stated. “Conversely, TOPCon modules experience significant degradation, with maximum power decreasing by 4–65% relative after the same DH testing duration.”

Popular content

Through the testing, the scientists identified, in particular, three kinds of failures: A point-localized failure; a failure mode that occurs at the interconnection point between ribbon wires and busbars of the cells; and a complete failure across the entire area of the cells and modules.

They attributed the cause of the first failure to the electrochemical reaction between moisture, cell metallization, and contaminants likely present on the cells before encapsulation. For the second type, they said it was observed in modules with TOPCon cells encapsulated with either EVA or POE, starting at the interconnection point and then spreading to the surrounding cell area after extended DH testing.

As for the Type-3 failure type, it was found to occur in modules with TOPCon modules encapsulated with POE, likely due to an electrochemical reaction between cell metallization, moisture, soldering flux, and critical elements released.

pv magazine

The May edition of pv magazine, out next week, examines global polysilicon oversupply and tightening finance in China, looks at the burgeoning solar glass industry in the US, updates readers on the latest perovskite progress, and considers how to develop PV when the bullets are flying. All this plus features from Turkey, Italy, Azerbaijan, and more.

The academics said these results show the vulnerability of TOPCon solar cells when exposed to high humidity and contaminants before encapsulation. “Careful consideration is necessary when handling and selecting encapsulants for TOPCon modules,” they warned.

Their findings were presented in the study “Buyer aware: Three new failure modes in TOPCon modules absent from PERC technology,” which was recently published in Solar Energy Materials and Solar Cells.

The same research group identified last year four failure modes caused by damp heat in heterojunction solar panels with a glass-back sheet configuration. These failures could result in power losses ranging from 5% to 50%.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Its good to see that academia is investigating the solar cell flooding of the market keep up the good work