Researchers at the Norwegian University of Science and Technology (NTNU) have studied the melting behavior of silicon kerf powder under various regimes and conditions, aiming to bring the material’s refining and recycling closer to commercial and technical implementation.

Silicon kerf is the silicon material that is lost as waste when a crystalline silicon ingot is sliced into thin wafers during solar cell production. “The recycling of silicon kerf has been quite topical for several years, and some lab-scale solutions have been proposed, however, there is not currently a well-established running industrial process for recycling it back to solar silicon due to the stringent purity requirements and scalability factors,” the research team explained.

Their analysis considered the melting behavior of silicon kerf agglomerates with different sizes.

They first dried a silicon kerf powder cake sourced from Norwegian manufacturer REC Solar Norway, then crushed it using a mortar and pestle. The powder was subsequently agglomerated in a drum pelletizer, and the resulting pellets were further dried. Finally, the dried pellets were melted using electromagnetic induction under various conditions and analyzed through glow discharge mass spectrometry (GDMS) for elemental compositions of impurity elements.

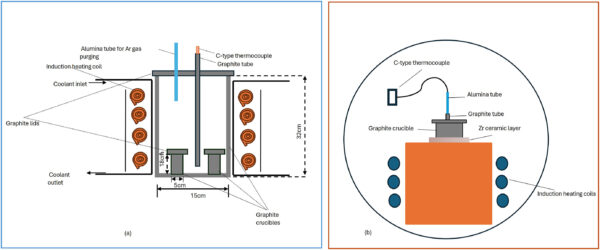

For their experiments, the scientists used a semi-closed 75 kW furnace and a closed controlled atmosphere induction furnace. Melting was carried out under different regimes at temperatures ranging from 1,600 C to 1,800 C

Image: Norwegian University of Science and Technology, Solar Energy Materials and Solar Cells, CC BY 4.0

Three different melting regimes were applied. In the first regime, the agglomerates were heated to the target temperature under an argon atmosphere, held for 30–60 minutes, and then slowly cooled in the furnace. In the second regime, the samples were heated to the target temperature and held under vacuum for 30–60 minutes. The third regime applied a vacuum during both heating and holding stages. The furnaces were equipped with a camera, allowing the assessment of the melting process in real time.

The silicon recycled after melting was then analyzed through scanning electron microscopy (SEM), glow discharge mass spectroscopy (GDMS), and electron probe micro-analyzer (EPMA), with the scientists finding that the size of silicon kerf agglomerates has little effect on their melting behavior. They also found, however, that melting under inert and vacuum conditions differs significantly. Indeed, vacuum promotes the vaporization of volatile elements and increased silicon monoxide (SiO) gas formation, enhancing deoxidation and resulting in better melting.

Furthermore, the analysis showed that, under an inert atmosphere at temperatures below 1,800 C and residence times of 30–120 minutes, a single homogeneous melt is not achieved. In contrast, vacuum melting enables simultaneous oxygen loss via SiO gas, producing an oxide-free single melt. In both atmospheres, SiO deposition occurs above the molten silicon and on the crucible surface, though the underlying reaction mechanisms differ between inert and vacuum conditions.

Their findings are available in the study “Mechanisms and melting behavior study of Si-kerf agglomerates under inert and vacuum conditions to recover PV silicon,” published in Solar Energy Materials and Solar Cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.