Distributed energy resources generally include a number of elements: solar or wind power, storage, along with emitting sources such as biomass and diesel generators, and a grid connection. The main benefit is that the facility or community can function as a true offgrid array or attached to the grid. Setups include the grid-tied, grid independent and islanded – while smart controls can switch configurations to the most advantageous through price and demand monitoring, depending on the quality of data available.

Advanced controls

Microgrids that use advanced control technology to manage generation and demand

optimize between on-site generation, storage, and the grid, with smart monitoring

of power prices to make automated decisions. Microgrids can also optimize for

self-consumption, minimize costs, carbon footprint optimization, or even to surpass

net-zero energy, and so on, with solar a key input for flexible microgrids.

For businesses, maximized solar production and self-consumption provides obvious benefits in revenue, reductions in emissions, and further demonstrates meaningful environmental, social, and governance (ESG) strategies for stakeholders.

On the consumption side, a facility with grid-connected solar but without storage can see times when a grid connection fails, resulting in lost solar production. Microgrids therefore provide control, flexibility and resilience to distributed energy resources operating together as a system. Microgrids cover multiple features which can be attractive to stakeholders, but any one issue may be enough: be it when a solar installation already exists or is being considered, when energy resilience and uptime is critical, when energy use and rates are high, or when the grid is unreliable. Microgrids have been deployed in applications ranging from corporate and academic campuses, right through to R&D facilities, data centers, industrial facilities, hospitals, military

bases and more.

Popular applications

Off-grid facility microgrids are the most common across the globe, found at remote sites such as mines or industrial sites and isolated accommodation like resorts.

Off-grid communities such as islands, or remote townships, are also a proven area. Business models for operation include the customer-owned, microgrid as a service

or pay as you go, and stakeholders must consider system design and development,

commissions, service, support, and funding.

Microgrids are becoming highly considered for facilities where climate change

risks are rising, such as coastal areas and those prone to flooding, storms, and rapidly

changing weather.

System flexibility

Off-grid solutions require durable, flexible inverters that are capable of optimizing

and handling rapidly changing inputs and demand. Growatt’s SPF 5000 ES offers resilience: it can utilize multi-ple power sources such as PV, diesel generation,

grid and battery. While supporting diverse electrical loads it can operate with or without a battery, but is compatible with both lithium and lead acid batteries, and also integrates a built in MPPT charge controller for battery charging. The wide maximum PV input voltage of up to 450 VDC, could effectively reduce the cable cost and there is

no need for an additional combiner box.

Parallel scaling is supported as well, with single-phase or three-phase operation of

up to six units with 30 kW max capacity. The system offers flexibility to support

PV and the grid jointly, while prioritising each and being remotely monitored

through WiFi or a GPRS dongle.

Storage options

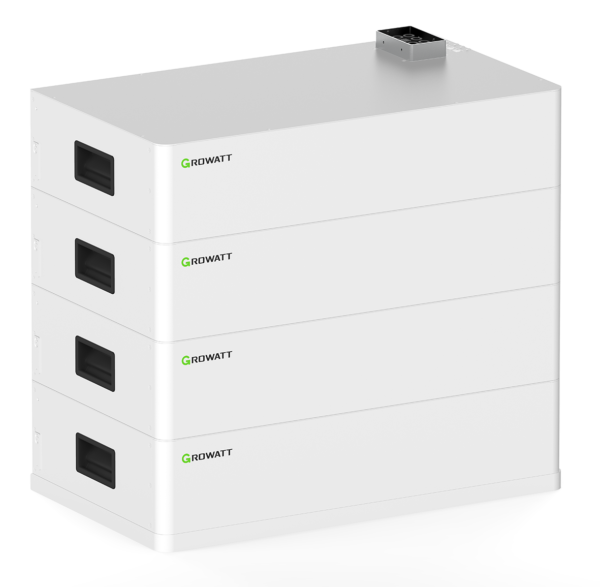

The SPF 5000 ES can be coupled with Growatt’s AXE Lithium Battery, a low voltage modular battery system that uses lithium iron phosphate battery cells (LFP) for maximum safety, offering 5 kWh per module.

Up to 10 modules can be linked into a single cluster for 50 kWh of storage, and a maximum of eight clusters can be joined to create 400 kWh of storage. The module design is stackable, and uniquely designed to connect via the stacking mechanism, without any additional cables to join batteries in a single cluster. Each weighs 45 kg, with an IP20 rating, and up to 60 A charging/discharging current.

A single SPF 5000 ES can handle as much as 6 kWp PV input, and simultaneously

supply a load with full power rating and charge a battery without an additional

solar charge controller (SCC). An SCC is usually required as an addition to the inverter to allow battery charging and supply to a load from a PV system. The system provides users with the smart management to configure multiple modes to satisfy different application scenarios such as peak shaving, maximizing solar consumption or power

backup.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.