Mondragon’s leading automated solution for photovoltaic applications has developed a Front Line with an annual production capacity of 150 MW.

Due to the decrease in raw material costs, photovoltaic energy has become one of the cheapest energy sources in the market, having achieved an exponential growth in recent years.

In light of this growth, module manufacturers increasingly require higher production lines with higher degrees of automation, which is why Mondragon Assembly has developed the most modern Front Line in the market.

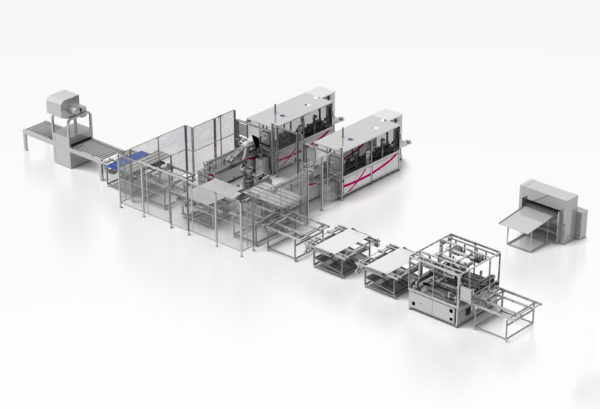

The Front Line consists of two MTS 2500 tabbers and stringers and an IC150 interconnect system. This Front Line is designed to manufacture panels with cells of up to 6 buses.

Tabber MTS 2500

The MTS 2500 tabber and stringer allows a net production capacity of 2400 cells per hour in a single welding track, making it the fastest in the market. In addition to its production capacity, it is also notable for its size, as it only requires 7.5 m2. It thus allows the installation of high-production lines in smaller areas.

IC150

As the number of busbars in the photovoltaic cells increases, the bussing, or interconnected welding process, becomes a bottleneck in many production chains. Mondragon Assembly’s IC150 allows module manufacturers to increase the production rate while ensuring the product quality at all times.