It is estimated N-type TOPCon capacity is between 120-130GW, accounting for approximately 30% of the market share, this share will grow to 60%-70% in 2024. 2024 appears to be the date by which you'll be able to get a TOPCon version of any new model you want.

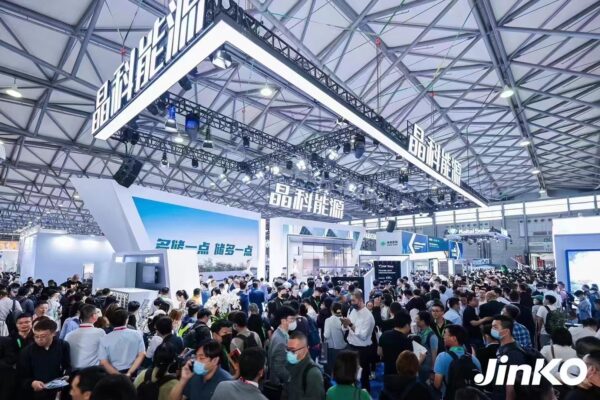

Mainstream solar module producers have already properly grappled with TOPCon or opted for the direction they're going. JinkoSolar gave possibly the favorite-feature TOPCon panel of the show, the Tiger Neo. Wonderful performance details abound, and you don’t doubt either of these will make them to production, to date this production version of TOPCon has delivered and installed over 20GW worldwide.

This is the beauty of TOPCon – higher efficiency, more power, more productivity, higher bifaciality, zero light-induced degradation, and lower temperature coefficient. TOPCon technology continues to evolve, “the mass-produced TOPCon cell efficiency will enhance from current 25.4% to 25.8% by Q4 this year,” said Dany Qian, VP of JinkoSolar.

As TOPCon quickly inches its way into the mainstream, early adopters are discovering that the yield gain of TOPCon in real-world condition projects is demonstrating an impressive 5% on average which is higher than the theoretical value of 3%. This is one of the primary considerations when designing the all-TOPCon projects.

The comparison data from those earlier adopters, in our view, are the main drivers of TOPCon adoption will be economic rather than supply-side shift towards TOPCon and parity in the total cost of investment is proved better than PERC that’s why TOPCon begins to make up a significant share of new sales.

At the same time, it often feels like everyone cares way more about productivity kWh per watt than just power kW. And while PERC light-induced degradation LID is surely a problem, so too is ever more under extremely hot weather. For the last one and a half years, JinkoSolar has proved it's possible to build a credible TOPCon that customers will aspire to.

Due to the established TOPCon supply chain, key manufacturers have prepared for the shift towards TOPCon and away from PERC regardless of where they are based. Though the transition toward 100% n-type is a nearer-term, every booth is reserved its best place to display its TOPCon models, it may pose the ultimate test of companies’ manufacturing excellence that can transfer the advanced technology from laboratory to the mass production line at low cost. Solar companies will need to catch up faster and remain nimble to thrive amid this shift. Companies that cannot provide N-type products may face a significant threat if they cannot adapt.