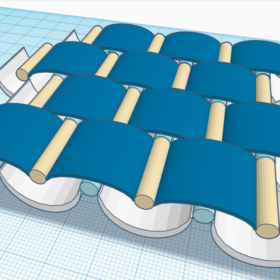

Solar module passive cooling with lapping fins

Malaysian researchers have proposed a new passive technology for solar module cooling based on fin heat sinks. The tech ensures lower PV system payback times and reduces operating module temperatures by up to 26 C.

Water-based cooling technique for photovoltaic-thermal systems

The novel technique consists of a PVC pipe with 20 holes that is placed on the top of a PV module and is able to maintain a constant discharge of water. It was demonstrated on an experimental photovoltaic-thermal PV system in which the PV panel was not integrated with the solar collector but connected to it via pipes.

Rectangular aluminum fins for PV module cooling

Scientists in Pakistan have proposed a new passive cooling technique which they claim can improve a module’s open-circuit voltage by up to 12.97% and its efficiency by up to 2.08%.

The best PV module cooling technique

An international research team has analyzed all existing cooling technologies for PV panels and has indicated the current best options and future trends of research. According to its findings, active water cooling, although expensive and not particularly practical, is the most effective cooling technique while passive cooling systems, despite being easy to apply, have still limited possibilities.

Cooling PV panels with regasification of liquefied natural gas

Researchers in Israel have suggested the use of regasification of liquefied natural gas to reduce the operating temperature of PV modules in solar parks located at gas terminals. According to them, the feasibility of such a cooling solution could be strengthened by the fact that both the PV systems and the LNG regasification systems are, separately, mature, economical technologies.

Cooling PV panels with seawater

An Anglo-Egyptian research group has developed a passive cooling method based on saturated activated alumina, with saline water as a cooling agent.

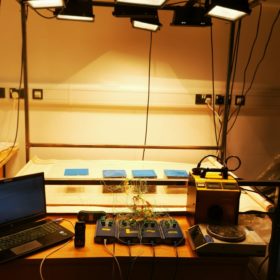

Active cooling for PV modules in floating arrays

Saudi Arabian and Pakistani scientists have created a serpentine cooling block structure to improve the efficiency of PV panels in floating solar projects by around 1.5%. The cooling block can be filled via a low-cost, 15.6 W commercial 12 V DC water pump with cool water.

Titanium oxide nanofluid-based cooling technique for PV panels

Indian and Malaysian scientists have developed a new cooling system featuring an assembled back-channel attached on the rear sides of solar panels, to channel flows of titanium oxide and water. They used a 0.6% nanofluid concentration – the optimum value of nanoparticle concentration in water.

Testing CPM-based passive cooling for CPV systems

An international research team has tested change material heat sinks for heat management on a concentrator photovoltaic system. It found that increasing over height ratios lowers the formation of stratified liquid layers, which in turn reduces the potential hot spots in the upper part of the solar cell.

Parabolic bifacial module with active cooling system

Scientists in Morocco have designed a new bifacial module with a cooling system, based on bifacial parabolic solar cells that are connected to each other via tubes for panel cooling. They are now patenting the tech, but have yet to manufacture an initial prototype.