New silver paste product promises TOPCon solar cell gains

China’s Solamet has launched a new silver paste product for tunnel oxide passivated contact (TOPCon) solar cells processed with laser carrier injection technology. By solving a problem related to contact between the paste and the boron doped front surface of the silicon cell, it promises an efficiency improvement of at least 0.2% over competing products.

Applying perovskite solar cells onto BIPV steel products

Swansea University will collaborate with Indian multinational Tata Steel to investigate perovskite solar cell materials that could be applied directly onto coated steel to make building-integrated PV components. The partnership will add to an “active buildings” project that the Welsh university has been running for several years.

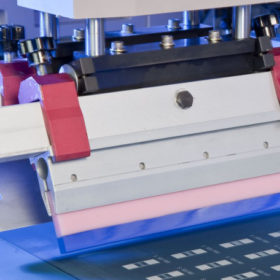

Simulating PV’s silver future

Scientists at Germany’s Fraunhofer ISE developed a model to simulate different setups for screen printing in solar cell metallization. The model provides a comparable ‘screen utility index’ value that can predict the usefulness of different architectures in the printing equipment in relation to the properties of a given silver paste. The approach, says Fraunhofer, will assist the PV industry in reducing the amounts of silver needed in silicon cell manufacturing.

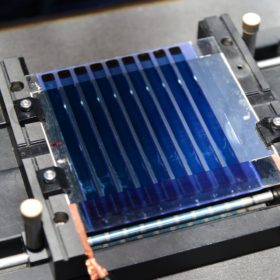

Copper metallization process reaches pilot production in Germany

Scientists led by staff from Germany’s Fraunhofer ISE have demonstrated a new laser printing process in pilot production, which could replace silver paste and screen printing in solar cell manufacturing. The system is said to offer much more flexibility in the layout of contact fingers on the cell surface and a wider choice of metallization materials.

More efficient large-area organic solar cells with spin coating

Researchers in South Korea have used the process to increase performance and the replicability of large-area organic cells. The method was used during film formation to speed up solvent evaporation.

Slimming down on silver

Using an innovative high-speed video setup, scientists in Germany were able to observe the screen-printing process used in solar cell metallization, on a time scale of less than 50 milliseconds. Insights into the paste’s behavior and the mechanisms at work during screen printing will improve the process and the formulation of the silver paste it relies on.