The New Energy Center at National Taiwan University and Taiwanese PV production equipment provider E-Sun Precision Industrial Co. have developed new production equipment to manufacture p-i-n type perovskite solar cells with large area.

Researchers from both entities said the machine can facilitate the production of “low-cost” perovskite cells through the MK-20 once-through process. The manufacturing process, which is based on slot-die coater and fast thermal processor (FTP) tech, is fully automatic and can currently handle small-quantity sample production.

“This machine can continuously carry out four layers thin-film coating and fast heat treatment in sintering and crystallization,” said Bin-Juine Huang, a professor at the New Energy Center.

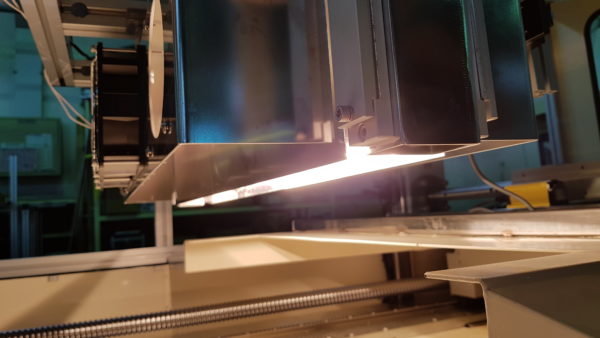

Image: National Taiwan University

The largest area that can be produced with the equipment is 80 cm × 80 cm. “For a typical p-i-n type perovskite cell, the trial run on this machine achieves 14.3% power conversion efficiency which is about 77% of small cell produced by spin coating and hot plate annealing,” the research group explained.

The new machine is ready for commercialization. It was developed under a research project supported by the Taiwanese government to produce large perovskite solar PV modules with dimensions of 1.6m x 1m, using perovskite solar cells made from MK-20.

Popular content

“MK-20 can only makes thin films of perovskite solar cells,” Huang stated. “It still needs the back electrode manufacture and cell modularization in order to make a solar PV module for practical power generation.”

The research team is also currently developing a low-cost lamination packaging process for large PV module production.

“Combining the low-cost perovskite cell production and the low-cost module packaging technologies, perovskite solar cell will be moved closer to the market side in the near future,” Huang added.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Not a word on the fact that the chemistry of these these cells includes lead bromide (PbBr2). These panels will eventually need disposal and then that lead will become a toxin in the environment. These cells might appear to be cheap but the final clean up cost could be high. The disastrous use of the ‘miracle’ mineral asbestos comes to mind. The asbestos environmental clean up cost has far exceeded the benefits accrued with using that material as a thermal insulator.