Above, a U.K. aerial inspection and data analytics specialist, has developed a way to monitor the construction of large-scale solar projects.

The company claims its approach reduces operational risks. It combines different technologies to optimize the deployment of solar PV plants, as well as operations and maintenance. The approach is based on its SolarGain software platform, which unifies all solar plant testing and inspection data within a collaborative, shareable environment.

“Our software was conceived to document the birth of an energy asset since its inception,” Above CEO Will Hitchcock told pv magazine. “It is offered to our clients during construction operations with the aim of derisking their projects.”

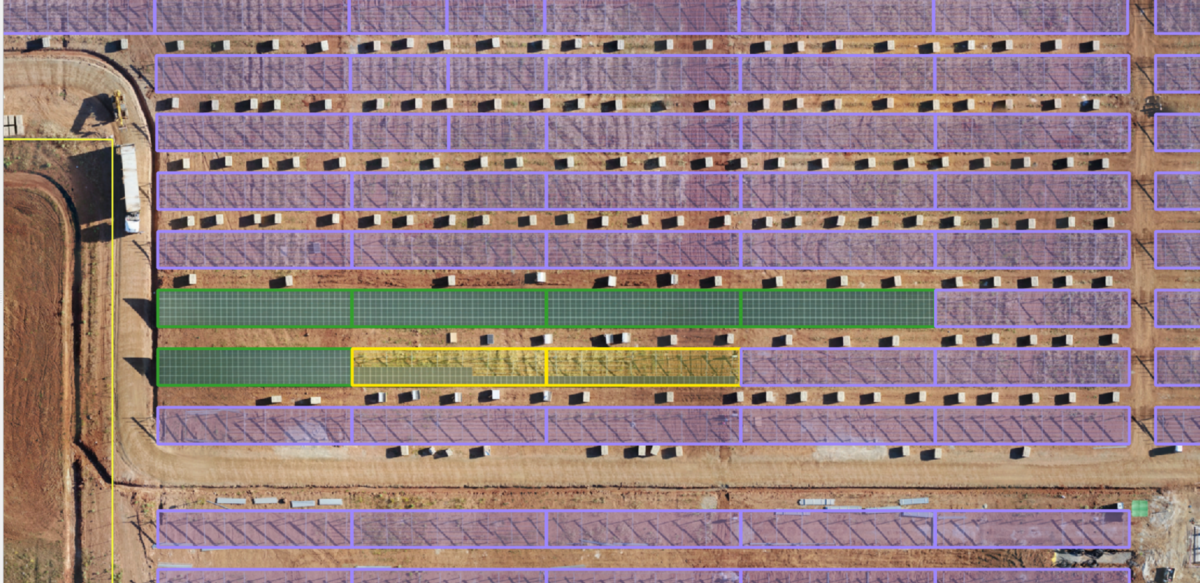

The company uses drones equipped with sensors and high-definition cameras to capture a highly accurate and detailed image of the solar plant construction site. The solar plant construction drawings are digitally placed over this image, along with a layer of colored blocks that represent solar panels, inverters, cable runs, and other components. The result, according to the company, is a fully interactive digital model of the site. Users can assess the construction progress, track project progress against milestones, record design deviations, and share project information with stakeholders.

They conducted detailed drone scans throughout the project, often by aligning the drone visits with key milestones. Each time new information was collected and processed into an orthomosaic, it appeared as a new layer within the platform.

“This comprehensive collection of data replaces static spreadsheets and PDF reports, thus providing more clarity and precision in one cloud platform,” Hitchcock said.

The service allows customers to generate ‘as-built' documentation during construction and create a permanent digital record for the future. This provides insight into future remedial tasks, technical due diligence, and asset transfers.

Once a solar plant project reaches the commissioning stage, the plant design has already been digitized. The software virtualizes all the site components within a virtual representation that is electrically and geospatially mapped. The software supports bulk data uploads of everything from factory flash tests to serial numbers. The platform can also integrate with SCADA monitoring to create an even larger data environment.

“Investors and EPC contractors can visualize all historical data and the different construction stages in an interactive environment and for different sections of the plant,” Hitchcock said, noting that the service is priced based on the size of the project site and the frequency of the scans.

He said that Above’s mobile inspection tool, EyeSite, helps to expedite this time-consuming process by enabling instant data uploads.

“For instance, a visual inspection can be recorded using EyeSite, uploaded to the digital twin, and then transformed into an EPC-ready punch list,” Hitchcock said. “Today there is more data than ever before, digital twins provide a permanent record for the future and a smooth transition into O&M.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.