Oxford PV today announced a new record efficiency for its perovskite/silicon tandem, edging ever closer to the 30% milestone at 29.52%. This achievement also places the technology ahead of single-junction cells of any material, further validating the case for tandem cells as ‘the future of PV’. The new efficiency record has been certified by the National Renewable Laboratory in the U.S.

While some are still to be convinced of the merits of perovskite solar cells, Oxford PV has long been a pioneer of the technology. An announcement from the company made today includes a calculation that 35kg of a perovskite material could generate the same amount of power as seven tons of silicon. And it further notes that perovskites have achieved similar conversion efficiencies to silicon with only ten years in development, while researchers have been working on silicon PV for more than 60 years.

The new record was achieved on a cell measuring 1.12cm², produced in a laboratory setting. Oxford PV previously held the tandem cell efficiency record at 27.3%, and then 28%, before a group at Helmholtz Zentrum Berlin (HZB) pushed the record to 29.15% in January 2020. Both Oxford PV and HZB have stated that they have clear roadmaps to push this record beyond 30% in the near future.

“Achieving another world record is a fantastic milestone for our perovskite-based solar cell, as it demonstrates that we are one step closer to the provision of highly powerful and lower-cost solar energy,” said Oxford PV CEO Frank Averdung. “We are currently at a global tipping point -climate change is dramatically worsening and the need to use alternative forms of energy has never been greater.”

Large scale production

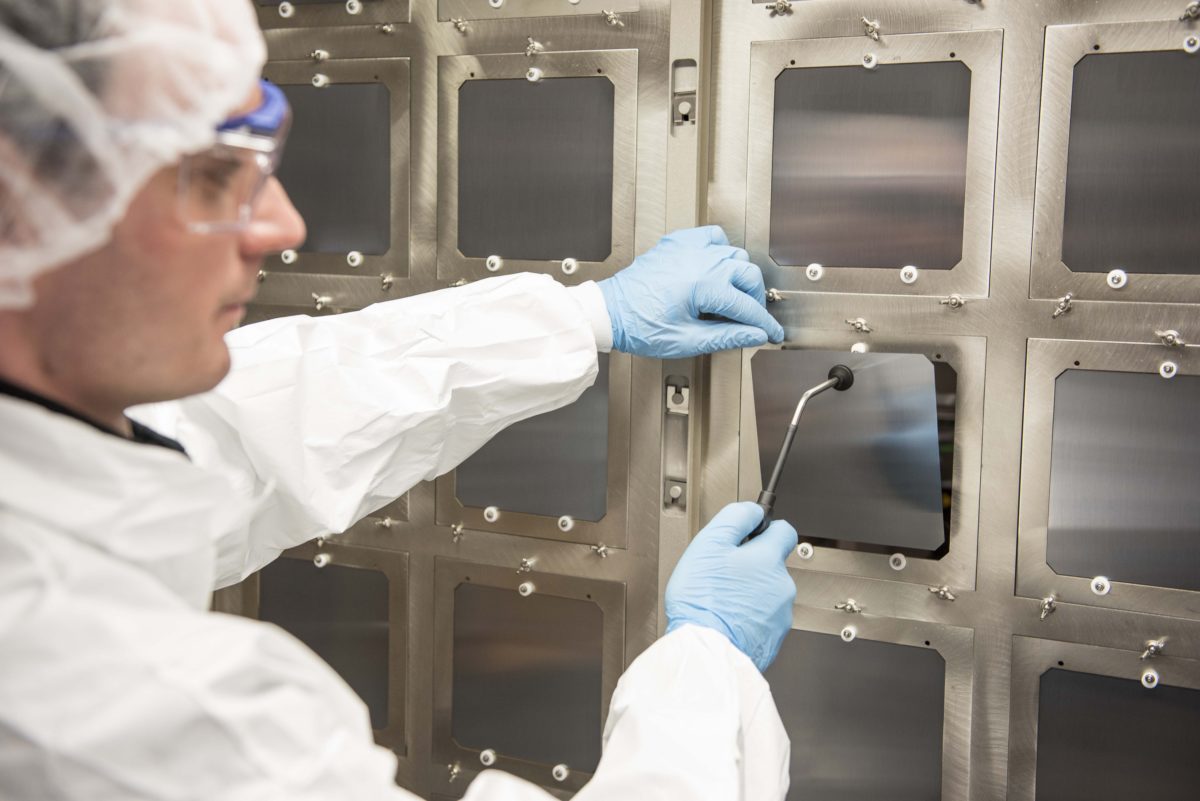

Oxford PV is in the process of ramping up the production of perovskite-silicon cells and modules at its facility in Germany. It is now targeting large-scale production in 2022, stating that due to the ongoing Covid-19 pandemic, delays in shipping equipment and work on the site have forced them to push back a previously targeted launch in mid-2021.

The company notes that although its new record-breaking cell was produced in laboratory conditions, it utilizes similar materials and processes to those it will use in mass production, and expects much of its research to be transferable.

And in further validation of its approach, Oxford PV now reports that its technology, although not in full size 60 cell module form, has been shown to meet industry standards for reliability in external testing. “Our solar cells and modules not only demonstrate record efficiency but have passed externally measured industry-standard reliability tests from the International Electrotechnical Commission. The considerable progress we have made is thanks to our dedicated and skilled scientists and engineers in the UK and a validation of the entire global perovskite research community who have been contributing to making perovskite successful,” said Oxford PV CTO Chris Case. “Our innovative approach is a breakthrough for solar power efficiency and will be instrumental in paving the way for an all-electric future.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

11 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.