Scientists at Carl von Ossietzky Universität in Oldenburg, Germany, have built a kesterite copper zinc tin selenide (CZTSe) thin-film solar cell by using thin diffusion-barrier layers of silicon oxynitride (SiOxNy) to reduce the thickness of the molybdenum diselenide (MoSe2) interface layer.

The researchers said the formation of a MoSe2 layer, with a thickness of up to 1 μm, is usually observed in the Mo/CZTSe back-contact interface during the CZTSe synthesis processes. Similar levels of thickness are seen as having a negative impact on cell performance. SiOxNy is described as a widely used passivation material with high-temperature durability, high oxidation resistance, and low defect density.

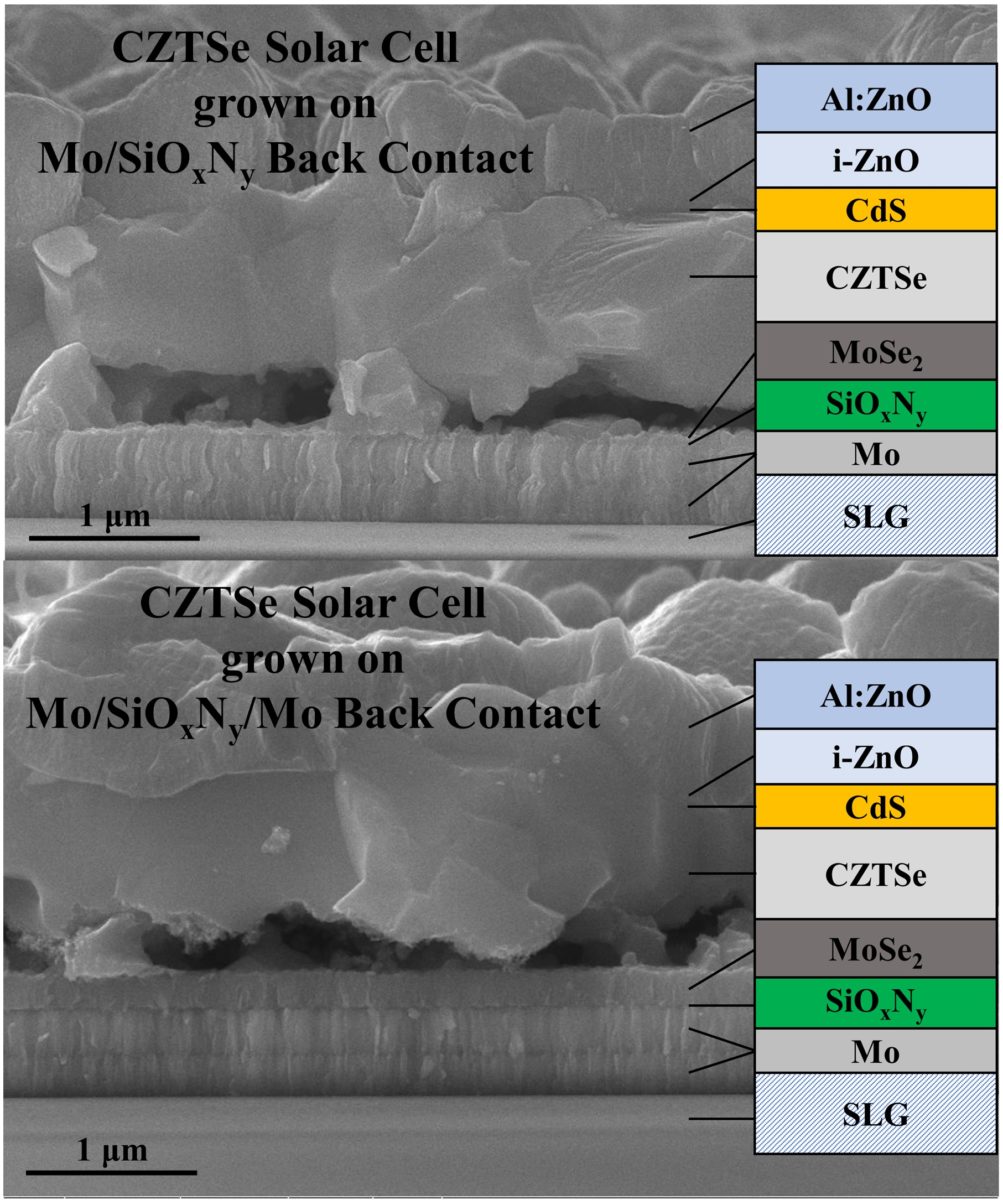

They applied two different types of back-contact structures: one with a sublayer of molybdenum and a sublayer of silicon oxynitride (Mo/SiOxNy), and one with two sublayers of molybdenum, and a sublayer of silicon oxynitride (Mo/SiOxNy/Mo.) The Mo layer was deposited by argon plasma, while the SiOxNy layer was deposited from silicon sputter target by mixed argon-dinitrogen-oxygen plasma treatment.

“For the formation of CZTSe absorber, a metallic precursor with a structure of zinc/copper-tin/zinc (Zn/Cu-Sn/Zn) was deposited onto the above-mentioned back contacts by DC-sputtering at room temperature, followed by the annealing with selenium (Se) pellets and tin (Sn) wires in a tube furnace at 530 C for 20 minutes,” the academics explained.

They deposited cadmium sulfide (CdS onto the CZTSe absorbers via a chemical bath. Two layers made of intrinsic zinc oxide (i-ZnO) and aluminum-doped zinc oxide (Al:ZnO) were deposited by radio frequency sputtering as front contacts.

The academics claim that the SiOxNy prevents the strong reaction of molybdenum and selenium from forming MoSe2 during annealing with a high temperature of around 520 C.

Popular content

“In cases of Mo/SiOxNy/Mo back contacts, the performance of CZTSe solar cells remain unchanged or slightly improved in the range of approximately 11% for the adoption of 10 nm SiOxNy layers,” they said. “As the SiOxNy layers get thicker, the efficiencies of the solar cells decrease much less in comparison to the Mo/SiOxNy cases.”

They described the proposed manufacturing technique in “SiOxNy back-contact barriers for CZTSe thin-film solar cells,” which was recently published in Plos One.

Kesterite solar cells were developed last year by South Korea's Incheon National University and the Gwangju Institute of Science and Technology, and by India’s SRM Institute of Science and Technology (SRMIST) and by Carl von Ossietzky Universität. In August 2018, Australian researchers achieved a 10% efficiency for a cell based on copper zinc tin sulfide, or sulfide kesterite. The world record for such cells is 12.6%, achieved by Japanese thin-film producer Solar Frontier in 2013.

Kesterite is one of the most promising light absorber material candidates for potential use in lower-cost thin-film solar cells. Kesterites are comprised of common elements, such as copper, tin, zinc and selenium. And unlike copper indium gallium selenide (CIGS) compounds, there are no supply bottlenecks expected in the future. However, kesterite is still less efficient than CIGS in mass production.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

6 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.