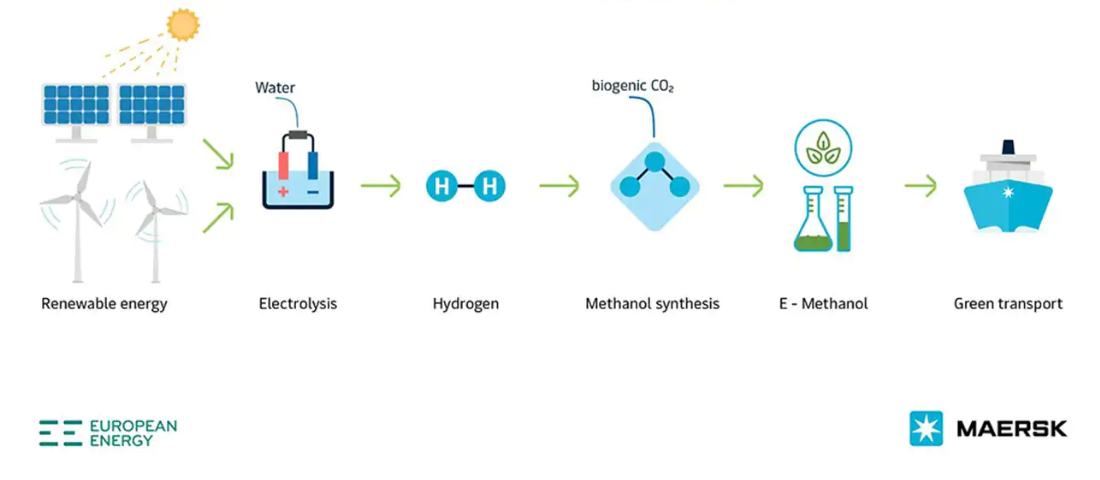

Copenhagen-based A.P. Moller-Maersk will team up with REintegrate, a subsidiary of the Danish renewable energy company European Energy, to produce green fuel for its first carbon-neutral methanol operated vessel. The methanol facility, which will use renewable energy and biogenic CO2, is expected to start operations in 2023. “REintegrate has a proven track record for producing green e-methanol with a test laboratory in Aalborg. The new facility will be its third e-methanol facility, as they are also constructing an e-methanol facility in Skive with startup 2022,” the company said. The energy will be provided by a solar farm in Kassø, Southern Denmark. “Sourcing the fuels of the future is a significant challenge, and we need to be able to scale production in time. This agreement with European Energy/REintegrate brings us on track to deliver on our ambition to have the world's first container vessel operated on carbon neutral methanol on the water by 2023,” said Henriette Hallberg Thygesen, CEO of Fleet & Strategic Brands, A.P. Moller – Maersk.

The government of the Chinese province of Inner Mongolia has approved a power project that will use solar and wind to produce green hydrogen, Bloomberg Green reported. According to the article, Inner Mongolia's Energy Administration has approved a plan to deploy to a cluster of plants in the cities of Ordos and Baotou. Overall, these plants will have a solar capacity of 1.85 GW and wind capacity of 370 and will be able produce 66,900 tons of green hydrogen a year. “Development will begin in October and the projects will be operational in mid-2023, the association said, without specifying the cost or the developers,” the article reads.

Researchers from the Monash University in Australia are looking at ways to produce hydrogen energy more sustainably through repurposing wastewater, the Australian public research university wrote on Thursday. “At least 5.5 billion litres of water is needed annually to achieve the hydrogen production target proposed in Australia's National Hydrogen Strategy for the estimated 2030 export market, which is equivalent to the annual water consumption of 1.6 million people,” reads the press release. The team is developing an approach that repurposes wastewater generated in Australia's major capital cities, minimizing freshwater consumption. “Most of the treated water throughout Australia is currently discharged to surrounding water bodies or recycled for irrigation after being treated in centralised municipal wastewater treatment plants. Given the volume of the treated water from these plants is highly consistent, it is a promising water source for water electrolysis,” said Chemical Engineering Professor and Director of the ARC Research Hub for Energy-efficient Separation, Xiwang Zhang. The project team will be working closely with national water utility companies Southeast Water, Melbourne Water, Yarra Valley Water, and Water Corporation, through Water Research Australia (WaterRA). “There still remains a knowledge gap in how the impurities affect water electrolyser design and process operation. Through this research we hope to develop an in-depth understanding of the impacts of water impurities in used water on the performance and durability of water electrolysers, and subsequently develop guidelines for the design of highly durable water electrolysers and the operation and upgrade of existing wastewater treatment plants,” said Arash Zamyadi from WaterRA.

Energy storage and clean fuel company ITM Power officially opened ITM Power's new factory at Bessemer Park in Sheffield, which the company called the world's largest electrolyzer factory. “ITM Power's Gigafactory, with a capacity of 1,000 MW (1GW) of electrolysis equipment per annum, commenced operation in January this year. The site already employs some 320 people with further staff additions planned as the facility ramps up to capacity,” the company said.

Popular content

South Korea's automobile parts maker Hyundai Mobis reportedly said it would invest 1.32 trillion won (US$1.1 billion) in two local hydrogen fuel-cell plants by 2025. The local news agency Yonhap wrote that Hyundai Mobis plans to build a hydrogen fuel-cell stack plant in Incheon, just west of Seoul, and a hydrogen fuel-cell systems assembly plant in Ulsan, 414 kilometers southeast of Seoul. The country is also researching a concept to develop an offshore green hydrogen model through a consortium focused on floating hydrogen production offshore plants (H-FPSO), and collaborating with foreign companies. On Wednesday, for instance, Loop Energy, a Canadian developer and manufacturer of hydrogen fuel cell-based solutions, said the “placement of the order for the first eFlow powered Hydrogen Fuel Cell Systems under a commercial agreement with NGVI, a South Korean-based manufacturer of turn-key compressed natural gas and hydrogen fuel systems for transit and coach bus applications.”

German gas and oil producer Wintershall Dea and Leipzig-based natural gas company VNG plan to build a facility to produce climate-friendly ‘turquoise' hydrogen as the first step of their long-term collaboration. “The thermal methane pyrolysis process used by HiiROC, in which both companies recently invested, is to be used and further developed for a specific application together with the facility manufacturer. According to current plans, the pilot facility will go into operation in 2023 and will have a nominal capacity of 400kg of hydrogen per day (equivalent to an annual energy output of almost 5 GWh). “This will make the facility the first of its kind to produce so-called turquoise hydrogen in Germany,” the companies said in a statement, noting that they have already jointly made an initial investment in England-based HiiROC to develop methane pyrolysis technology. “This cooperation with VNG will help realise the technology's potential and establish a hydrogen market, because markets don't happen by themselves. They have to be built and organised – technology neutral,” said Hugo Dijkgraaf, Chief Technology Officer at Wintershall Dea.

The British government awarded funding for four projects through the Advanced Propulsion Centre (APC) Collaborative Research and Development competition, which supports the development of innovative low carbon automotive technology. Among them there is the Brunel project in Darlington, which secured £14.6 million to develop a novel zero-emission, hydrogen-fueled engine to help decarbonize heavy goods vehicles. “This project will significantly accelerate the pace of hydrogen engine development, ensuring that the UK is in the vanguard of this exciting new technology which will play a significant part in de-carbonising the global commercial vehicle fleet,” Jonathan Atkinson, Executive Director of Cummins On-highway Business in Europe, said on Wednesday. The other selected projects are REEcorner in Nuneaton (£41.2 million to redesign light and medium-sized commercial electric vehicles), BMW-UK-BEV in Oxford (£26.2 million to develop an electric battery), and Celeritas in Birmingham (£9.7 million to create ultra-fast charging batteries).

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.