Researchers at the Universitat Politècnica de Catalunya (UPC) in Spain have fabricated a crystalline silicon solar cell based on vanadium oxide (V2O5) films used as a hole-selective layer.

The novelty of their approach consists of replacing thermal evaporation with atomic layer deposition (ALD) for the deposition of the films. The former is said to create potential scalability problems when the manufacturing process to build V2O5 crystalline PV devices reaches an industrial scale, as it requires the addition of a plasma-enhanced chemical vapor deposition (PECVD) passivating layer.

“The atomic layer deposition (ALD) process provides soft and low-temperature deposition techniques compatible with solar cell fabrication, as well as, it allows conformal deposition of films with a higher degree of scalability to industrial production than the thermal evaporation process,” the Spanish group explained. “Moreover, the superior surface passivation on silicon substrates provided by vanadium oxide films has the advantage to potentially overcome the need to use an amorphous silicon film as a passivating interlayer, eliminating a fabrication step and reducing the overall cost.”

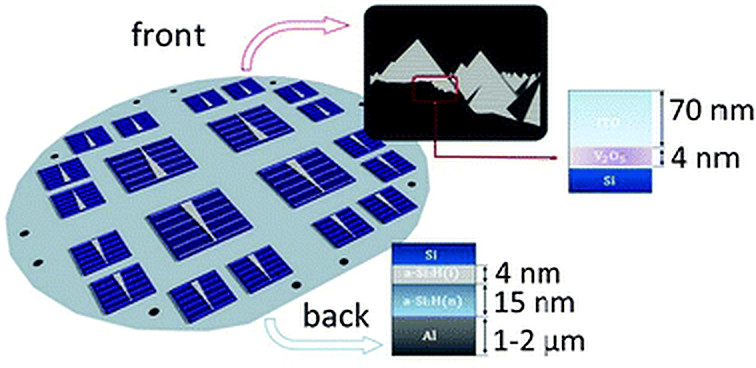

The solar cell was built with a high-quality float zone n-type c-Si wafer and a 4 nm thick V2O5 layer. The deposition process was carried out at 125 degrees Celsius and the vanadium precursor was heated to 58 degrees Celsius. The 70 nm thick indium-tin-oxide (ITO) film was deposited using radio-frequency (RF) magnetron sputtering, which is a high-rate vacuum coating technique that allows the deposition of many types of materials, including metals and ceramics. A 200 nm thick silver layer was then thermally evaporated over the ITO film.

Popular content

The solar cell showed a power conversion efficiency of 18.6%, an open-circuit voltage of 631 mV, a short-circuit current of 38.36 mA cm−2, and a fill factor of 75.8%. “The top solar cell achieved significant performance parameters with an efficiency of up to ∼19% without passivation from amorphous silicon,” the scientists emphasized. “Technological improvements in cell fabrication, such as better electrical quality of the ITO layer and/or a thicker silver grid could improve current efficiencies.”

The device is presented in the paper Atomic layer deposition of vanadium oxide films for crystalline silicon solar cells, published in Material Advances.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.