An international research group has developed a mathematical model to investigate how photovoltaics may be used to power multistage flashing-brine recirculation (MSF-BR) water desalination plants.

MSF plants have high energy consumption compared with other desalination technologies and, at the same time, can be driven by renewable energy with high quality of production. These plants generate about 26% of all desalinated water in the world and, if coupled with BR and solar energy, could be cheaper than reverse osmosis (RO) if the salinity is higher than 10,000 ppm, according to the scientists.

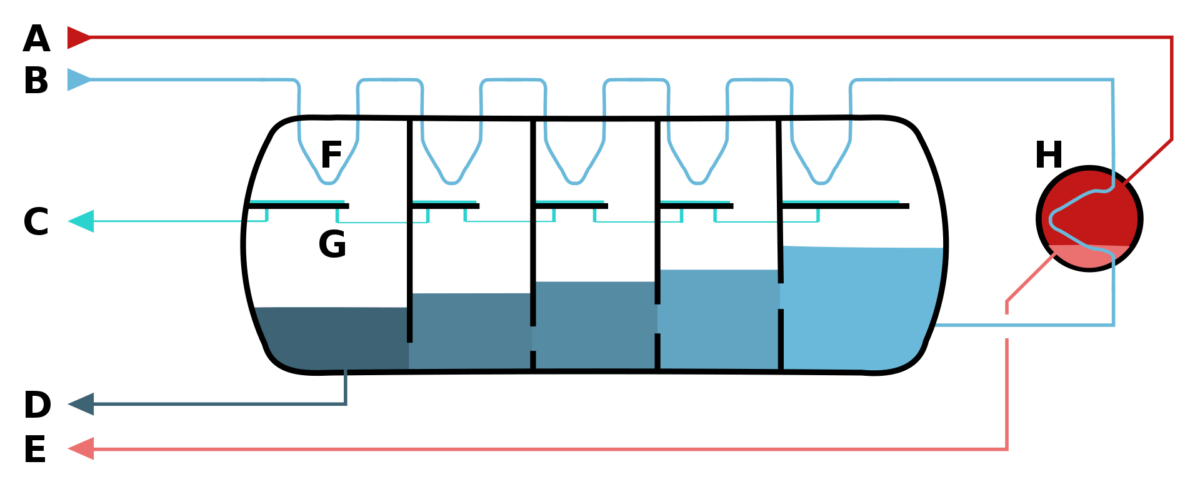

“A MSF plant consists mainly of a multi-flash evaporator, which consists of a heat recovery section and a heat rejection section, to reduce the excess energy from the system,” they explained. This kind of evaporator is commonly utilized for producing fresh water from seawater, well water, or industrial water.

They designed a system planned for the Jordanian city of Aqaba comprising a standard MSF-BR plant coupled with a 30 MW solar array, of which only 15 MW are used to power the desalination facility during daily hours, with the electricity produced by the remaining 15 MW being injected into the grid. At night, the plant is powered by the grid. The proposed project uses Trina solar 325 W, 72 multi-crystalline poly PV panels rated for operation, the research group stated. “The initial design for the project considers that the panels will be installed in a four high land scope orientation on fixed racks oriented south at an inclination of 25.31°.”

The solar modules are deployed in 3 × 5 blocks, with each block having 15 groups. Each group has less than 20 strings, and each string includes up to 22 panels. “The MSF-BR plant consists of 24 stages divided into two parts, as the first consists of the 21st stage, which reflects the heat recovery section, and three stages of the heat rejection section,” the researchers explained, noting that the solar-powered facility is also able to generate 6.52 kg/s of steam at 180 °C by using an electric boiler with high efficiency. This steam is then used through a shell-tube heat exchanger to increase the temperature of recycled brine.

The system design is claimed to be able to provide 5,470 m3 of desalinated water per day. “During the treatment process, the salinity concentration rises from 42,000 ppm to the maximum allowable value of about 68,822 ppm,” the scientists emphasized. “The total area of the heat recovery section is 14,559.8 m2, while the total area of the heat rejection section is 1663.8 m2.”

The proposed system configuration would be sufficient only to meet the demand for drinking water in Aqaba, which does not have much space available to construct larger facilities than that designed by the scientists.

Their findings are presented in the study Performance of dual multistage flashing – recycled brine and solar power plant, in the framework of the water-energy nexus, recently published in Energy Nexus. The research team comprises academics from the University of Perugia in Italy and the Al-Balqa’ Applied University in Jordan.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.