US-based start-up mPower Technology, a spin-off of the Department of Energy's Sandia National Laboratories, has developed a flexible monocrystalline silicon solar module technology, called DragonScales, which it claims can be used for both space and terrestrial applications.

“Our main business is expected to be in the space solar cell segment,” the company's president and CEO, Kevin Hell , told pv magazine. “But we are also planning to enter the building-integrated photovoltaics (BIPV) business, as our products could be easily used for residential and commercial projects, and to produce solar modules for soldier portable and shelter power applications.”

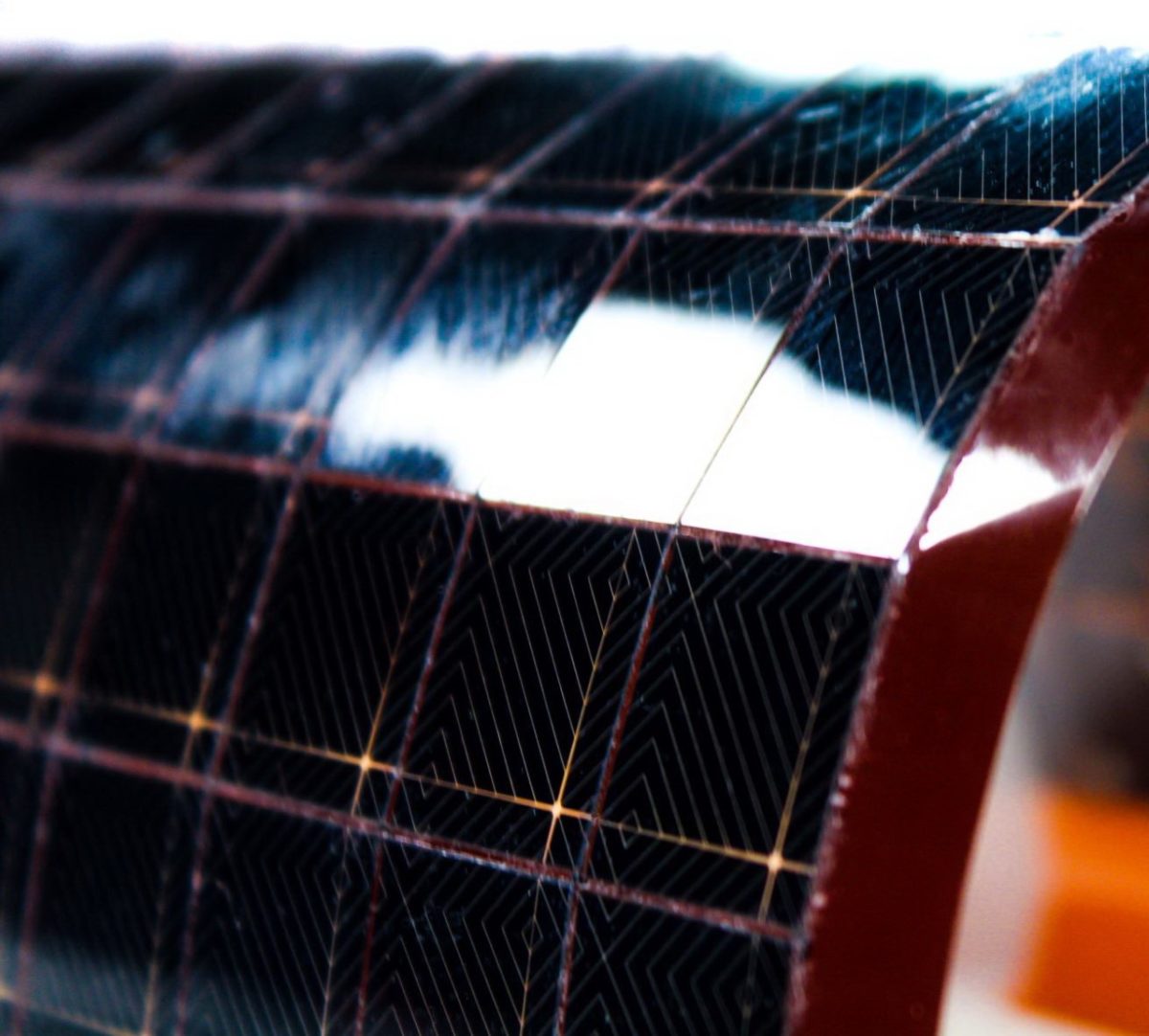

The fully encapsulated modules are fabricated with conventional back contact silicon solar cells with a thickness of 150 um or less and are assembled using existing high-volume fabrication processes from the microelectronics industry. “Our pilot line is a conventional machine for the production of semiconductors that has been adapted to the manufacturing of our flexible solar modules,” mPower CTO Murat Okandan stated. “The panels can be customized according to the customers' needs and adapted to different applications.”

According to the manufacturer, its production equipment can produce very high volumes of modules and allow rapid scaling as needed by the customers and applications for space.

The back-contact solar panels consist of micro-singulated silicon dies that are “hyper-interconnected” in series or in parallel. According to the company, the design allows customization of its “super modules” to any shape, thickness, voltage, size, material stack, and other design considerations to meet application-specific requirements at the lowest cost.

The modules feature efficiencies ranging from 22 to 23% and temperature coefficients spanning from 0.4 to 0.27 percent per degree Celsius, depending on the size or applications. Since the interconnect design is very customizable, it is possible to provide high voltage/low current or other desired array configuration details to fit the desired physical footprint and achieve the highest possible power delivery, the company stated. This is also claimed to bring in a very high level of innate electrical and mechanical resilience at the system level.

Popular content

This approach, according to the manufacturer, leverages the massive scale and high power of the terrestrial silicon PV market to minimize cost, while eliminating the challenging, hard-to-scale models of custom cell manufacturing.

“Our products are more expensive than conventional PV panels, but they are three to five times less expensive than III-V modules based on gallium arsenide for applications in space,” Hell further explained. “They are also significantly lighter since they are flexible and thus require less structural materials.”

At the beginning of February, mPower raised $10 million in a Series B financing round. The funds will be used to scale up the company's manufacturing facility and integration and test facility in Albuquerque, New Mexico, and to further develop the cell technology.

The production line currently has a capacity of 100 kW and the company plans to expand it to 1.5 MW. The yearly volume is projected to reach around 50 MW by 2025.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.