Scientists at the University of Kurdistan in Iran have simulated a four-terminal (4T) all perovskite tandem solar cell with optimized layer thickness and long-term moisture resistance.

In the study “Investigation of optical and electrical properties of novel 4T all perovskite tandem solar cell,” published in scientific reports, the researchers explained that they utilized a three-dimensional (3D) finite element method (FEM), which is a numerical technique used to perform finite element analysis (FEA) of any given physical phenomenon, for the numerical modeling of the 4T cell.

The tandem device is claimed to have low production costs, high efficiency, excellent mechanical flexibility, and self-cleaning and eco-friendly characteristics. The absorption properties of the wide bandgap (WBG) absorber material on top of the rear cell with a narrow bandgap (NBG) active layer were investigated for different cell configurations. “The electrical properties of each subcell and tandem device are analyzed for all of the considered cases, and the optimal structure is introduced to get the highest possible total power conversion efficiencies,” the Iranian group explained.

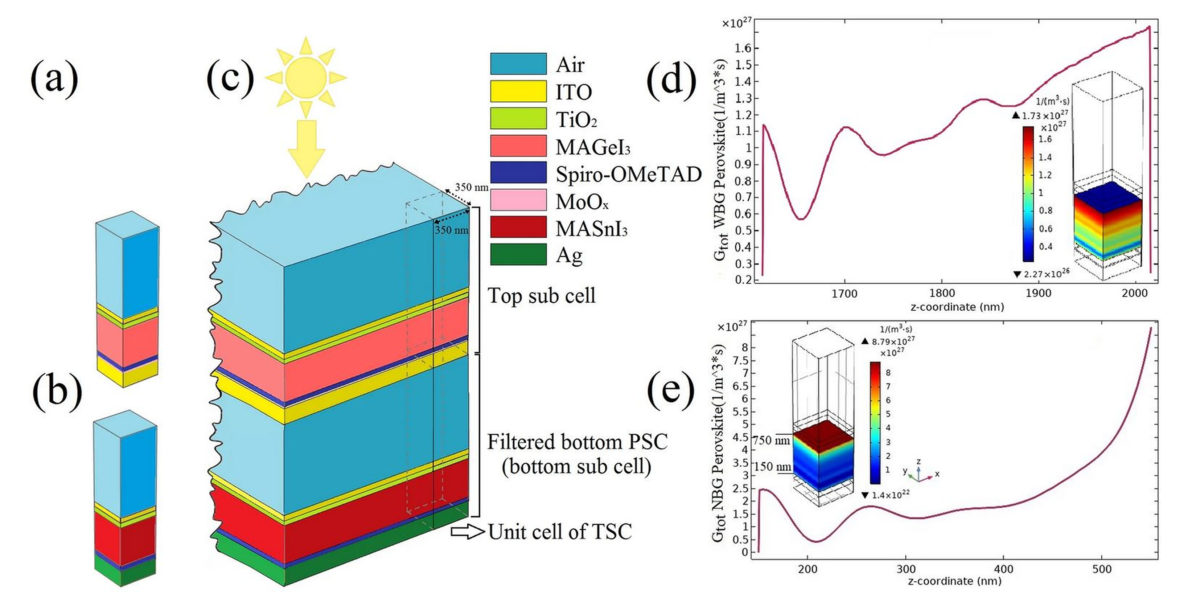

For the top subcell, the academics considered a perovskite known as MAGeI3, with an energy bandgap of 1.9 V, and a perovskite known as MASnI3, with an energy bandgap of 1.3 V, for the bottom subcell.

The semi-transparent top subcell was made with a transparent conductive oxide made of indium tin oxide (ITO), an electron transport material (ETM) based on titanium dioxide (TiO2), the MAGeI3 layer, a hole transport material (HTM) made of Spiro–OMeTAD, and a buffer layer relying on molybdenum oxide (MoOx). The bottom subcell layers from top to bottom are the ITO as the transparent conductive oxide (TCO), TiO2 as the ETM, MASnI3, Spiro–OMeTAD as the HTM and the gold (Ag) as the back-contact. “In order to design a flexible solar cell, we considered polyethylene terephthalate (PET) as the substrate of two sub cells,” the research team specified.

The highest efficiency value for the proposed cell configuration was initially found to be 24.65%. The scientists, however, proposed a design without the buffer layer and with the addition of anti-reflection layer (ARL) strategies, as well as the use of periodic nano-texture patterns. “By direct sputtering of the TCO on the HTM, not only parasitic absorption as optical loss will be reduced, but also an extra process step in the fabrication will be omitted,” they emphasized.

They also utilized a plasma-polymer-fluorocarbon (PPFC) coating on the plastic substrate as an ARL due to its low refractive index, excellent flexibility, nature of the superhydrophobic surface, high transmittance over a wide wavelength range, self-cleaning effect, and long-term environmental stability under high humidity, chemicals, and heat. Nano-photonic and nano-plasmonic structures were used to reduce total reflection losses at the wavelength range of 370–440 nm.

“The final structure is offered as a 4T tandem solar cell (TSC) that is environmentally friendly, extremely flexible, and has self-cleaning capability, with a total power conversion efficiency of 30.14%, which is greater than the total PCE of the reference structure by 22.27%,” the scientists concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.