A research group led by the Netherlands Organisation for Applied Scientific Research (TNO) has developed a new solar control window technology based on thermochromic smart glass.

The glass can change its infrared transmittance when hit by incident solar radiation as the temperature increases. It does not become visibly darker, as the effect only happens in the infrared part of the solar spectrum, so it becomes less transparent for solar heat.

“It would be possible to combine our technology with a PV window,” researcher Paskal Buskens told pv magazine. “But depending on the PV technology you use, the wavelengths would need to be synchronized, so that the thermochromic material doesn’t block wavelengths that are used by the PV to harvest energy. Such an idea came around in some discussions, but is not actively followed up on at the moment.”

The research group used vanadium dioxide (VO2) as a functional material in the pigmented polymer film coating, as it changes its crystal structure and therefore its optical properties at high temperatures. The thermochromic coating was combined with a standard low-emission (low-E) coated glass.

“Thermochromics can switch their infrared modulating properties from transmissive to blocking depending on the glazing temperature,” Buskens said. “The integration of VO2 into a film or coating for application in smart thermochromic windows can lead to a significant reduction in energy consumption for heating and cooling of buildings in intermediate climate.”

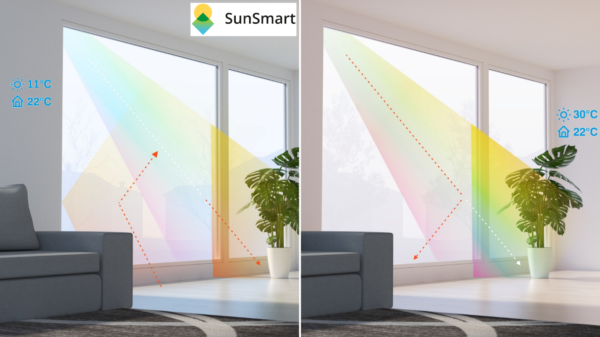

The proposed solar window concept works by blocking the heat from the sun when outdoor temperatures are high, while absorbing heat in colder weather.

“VO2 changes its crystal structure at a certain temperature,” Buskens explained. “With this change in the crystal structure, also the electrical and optical properties change, which means that the material absorbs more infrared light in the high-temperature crystal phase and the absorbed solar energy is not transmitted into the building.”

In the cold temperature crystal phase, most infrared light is transmitted and can therefore enter the building. The temperature at which the material switches can be adjusted via metal ion doping and can therefore be tuned for optimum energy savings.

In the cold temperature crystal phase, most infrared light is transmitted and can therefore enter the building. The temperature at which the material switches can be adjusted via metal ion doping and can therefore be tuned for optimum energy savings.

Popular content

“The most optimum switching temperature is around 20 C,” Buskens said.

The researchers claim the smart window can ensure energy savings of up to 8% in free-standing buildings, duplexes, and terrace houses.

“For apartments with large window areas even higher energy savings of up to 30% can be reached,” they said. “In total, the thermochromic coating adds between €6.00 ($6.09) to €7.50 per square meter in cost savings to standard low-E glass, which is currently used in newly built homes. Here due to low additional production costs, a return on investment within seven years is feasible.”

According to Buskens, energy savings and annual cost savings depend on the performance of the window and the building. “Therefore, these values can vary a lot and we try to bring some consistency into the reporting,” he said.

The scientists said material and application costs for the thermochromic laminate came to between €3.00 to €5 .00 per square meter.

“The final costs for the end-user will very much depend on the glass companies selling the product,” Busken said. “But due to the low costs for the material itself and the large potential saving an attractive business case is ensured, whilst keeping the return on investment for end-users at an acceptable level of around seven years.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.