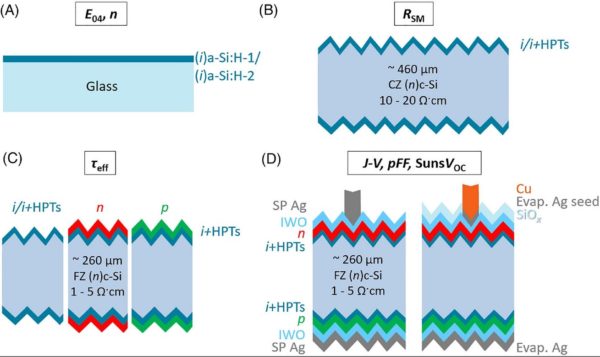

A research group from the Delft University of Technology has built a silicon heterojunction solar cell through a new passivation technique based on the use of an intrinsic hydrogenated amorphous silicon ((i)a-Si:H) layer. “The manufacturing process we developed is immediately applicable to commercial production,” the research's corresponding author, Yifeng Zhao, told pv magazine.

The scientists used an optimized post-hydrogen plasma treatment (HPT) to enhance the surface passivation qualities of the (i)a-Si:H layers, which were deposited through a multi-chamber plasma-enhanced chemical vapor deposition (PECVD) tool under various temperatures between 140 C and 200 C.

They also applied a very-high-frequency (VHF) treatment to improve the quality of the passivation process. “The VHF treatment consists of highly H-diluted SiH4 plasma, which mainly modifies the microstructure of (i)a-Si:H layers rather than depositing (i)nc-Si:H, as no change in the thickness of (i)a-Si:H was detected via spectroscopic ellipsometry (SE) after 6 min of this VHF treatment,” they explained.

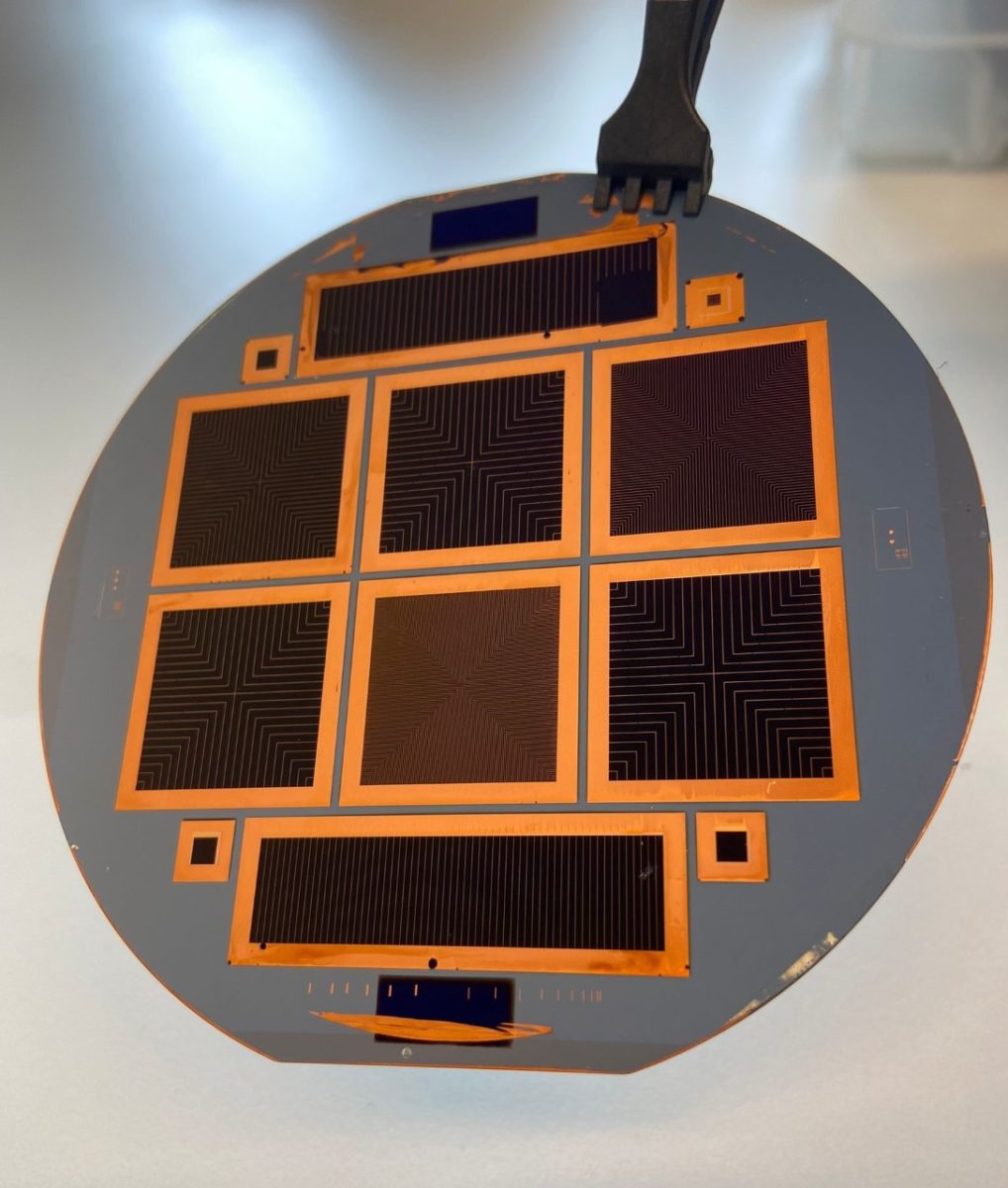

Image: Delft University of Technology, Progress in Photovoltaics, Commons License CC BY 4.0

The research group utilized Fourier-transform infrared (FTIR) spectroscopy to measure the microstructural evolution of (i)a-Si:H layers under various conditions. “Interestingly, porous films deposited under lower temperatures exhibited significantly improved and better passivation qualities with additionally applied HPTs, which favor the formation of porous and H-rich film,” it stated. “Besides, we also noticed distinctive peaks around Si-H W-RM in the infrared spectra, which seemingly reveal microstructural properties of thin-film (i)a-Si:H layers that are still unclear, for which further investigations on the vibrational origins of those peaks are still required.”

Popular content

The solar cell built with this manufacturing technique at 160 C achieved an in-house-certified power conversion efficiency of 24.18%, an open-circuit voltage of 726.0 mV, a short-circuit current of 39.97 mA/cm2, and a fill factor of 83.3%. This cell features further improved thickness combinations of the p-layer. A similar cell built at 160 C without the improvement of the p-layer achieved an efficiency of 23.71%, an open-circuit voltage of 724.5 mV, a short-circuit current of 39.81 mA/cm2, and a fill factor of 82.2%

“As the deposition temperature of (i)a-Si:H and associated material properties affect solar cell performance, we showed that high performance devices should meet critical requirements in optimizing the (i)a-Si:H that are not only limited to an excellent surface passivation quality to reduce losses induced by interface recombination,” the academics explained.

They presented the cell in the paper “Effects of (i)a-Si:H deposition temperature on high-efficiency silicon heterojunction solar cells,” published in Progress in Photovoltaics. “We demonstrate that carefully optimizing (i)a-Si:H layers that fulfill both requirements can contribute to higher SHJ solar cell efficiencies,” they concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.