From pv magazine USA

The French Alternative Energies and Atomic Energy Commission (CEA) has confirmed that Solestial's solar cells are able to repair radiation-related damage. Its tests have confirmed that the silicon cells effectively anneal radiation damage under sunlight at 194 F (90 C). Annealing is the process of slowly cooling to remove internal stresses of a material.

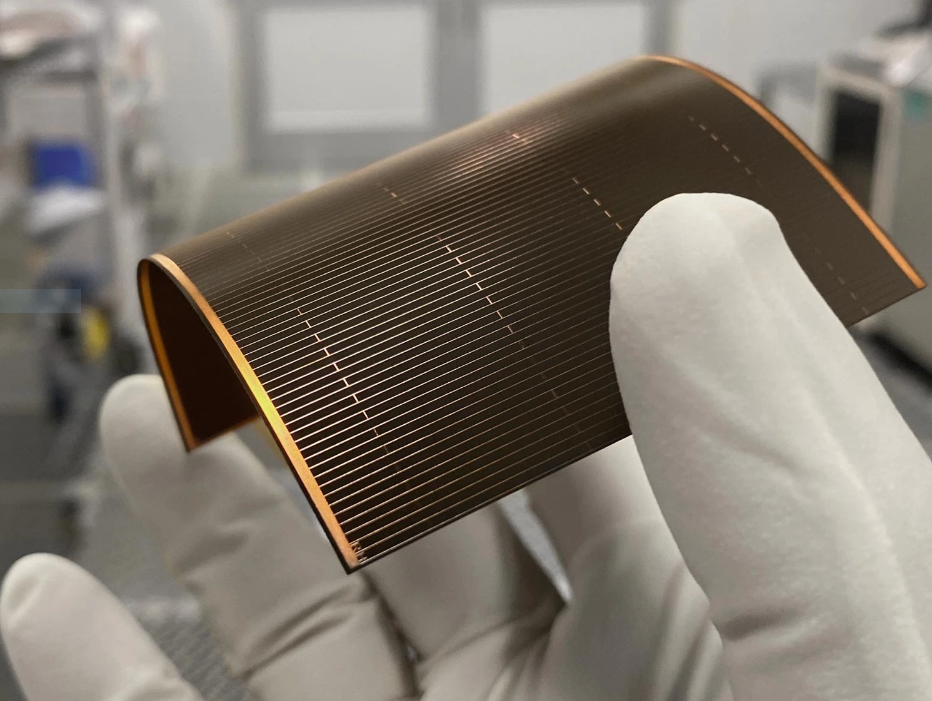

The open-circuit voltage of Solestial’s silicon solar cells dropped by only 4% and maintained 96% of their initial value after being exposed to radiation equivalent to 10 years in low Earth orbit and annealing at 194 F under one Sun illumination equivalent. The company said its 20-micron thick cells demonstrate more than 20% efficiency.

The company said the tests demonstrate the feasibility of self-curing solar cells with substantially reduced radiation-induced degradation. This is particularly important for space-based solar cells, which are buffeted by high levels of radiation and are required to operate for long lifecycles.

“Annealing of radiation damage in silicon is straightforward at high temperatures, for example, above 200 C to 250 C, but this is not useful for applications in space as these temperatures are rarely, if ever, experienced in situ,” said Romain Cariou, a space silicon solar applications expert for CEA. “The differentiation factor here is that Solestial’s cells can cure radiation damage at normal operating temperatures for solar panels in space.”

Popular content

Cariou said this response to irradiation cannot be found in current commercial cell technologies. Over the course of a 10-year mission, commonly used III-V multijunction solar panels will lose 10% to 15% of the beginning of their life efficiency due to radiation damage alone. For conventional terrestrial silicon solar panels, the damage will be even greater at 35% to 40%. Neither III-V nor terrestrial silicon have shown independent laboratory validation of such significant low-temperature annealing, said Solestial.

“We look forward to further testing with the CEA over the coming months to validate internal annealing results at even lower temperatures,” said Stanislau Herasimenka, chief executive officer of Solestial. “We’re excited to show the space industry the myriad benefits of Solestial’s ultrathin silicon solar cells and blankets.”

The company said another advantage of its technology is that it is silicon-based, while many other solar panels made from space are often made from rarer or more expensive materials like gallium arsenide. The Arizona-based company has been developing its technology for over a decade, beginning its life in Arizona State University. It underwent a $10 million seed funding round in October 2022.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.