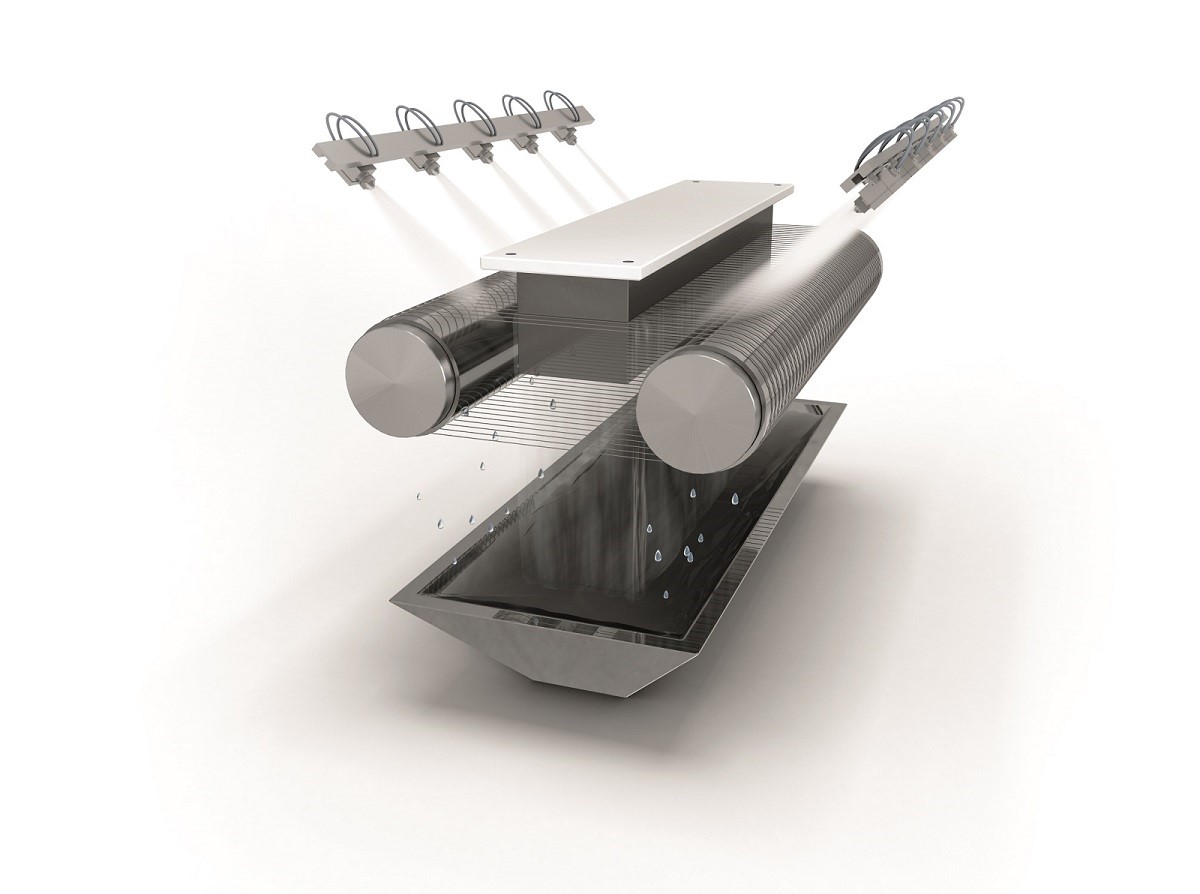

Evonik has announced the launch of new wetting agents and defoamers for PV wafer-cutting equipment. Its Tego Surten E products are advanced cutting fluids designed for high-speed diamond and multi-wire sawing processes. These fluids are specifically formulated to work effectively with thinner wires in cutting systems.

Evonik's wetting and defoaming solutions facilitate faster and improved wafer cutting, even when using harder or more brittle materials. These products are specifically designed to support high-performance wafer-cutting processes, faster draw speeds, and thinner wire diameters in both single and multiple circular cutting systems.

The low-foaming formulations offered by Evonik feature an “ultra-low” dynamic surface tension, effectively removing cutting swarf and maintaining clear wafer surfaces. This leads to significantly enhanced cut-quality ratios, higher cutting speeds, and reduced dosing rates compared to previous methods. Optimal system optimization can result in higher quality A+ wafers with fewer cutting-related defects, using less cutting fluid.

Additionally, the product line includes coolants that extend the lifespan of cutting wires, providing a cost-saving advantage over time.

The product launch occurred at the recent SNEC PV Power Expo in Shanghai, China. Alongside the introduction of Tego Surten E wetting agents and defoamers, Evonik showcased various other PV manufacturing products, including Dynasylan functional silanes, Vestoplast adhesives and sealants, and Polyvest plasticizers.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.