To address the challenge of characterizing curved, three-dimensional vehicle-integrated photovoltaics (VIPV), scientists at the Polytechnic University of Madrid developed the design principles and setup requirements for a solar simulator.

“We are considering commercial production in the future,” the corresponding author, Guido Vallerotto, told pv magazine. “For the moment, we are still improving several aspects of the simulator. The version we used for the characterization in the paper is not ready for commercialization, even if practically it is fully operational and functioning.”

In a test of a module with a radius of curvature of 1 meter, the research team found that their solar simulator’s measurements of the short-circuit current of the cells followed the ideal cosine response of the curvature with differences lower than 0.5%.

It also ascertained that a non-collimated light source, typically used in conventional solar simulators for flat modules, had a non-uniformity boost of between 2% and 20%, depending on the module. The intrinsic lack of uniformity under normal irradiance caused by the curved shape is boosted when it is illuminated with a non-collimated light source, said the researchers.

The researchers tested their solar simulator solution on one flat panel and three curved modules, with radii of curvature of 3m, 2m and 1m, respectively. The modules were equipped with 32 metal wrap-through (MWT) cells with eight strings of 4 cells. Each string was measured independently and compared to the expected cosine response.

Popular content

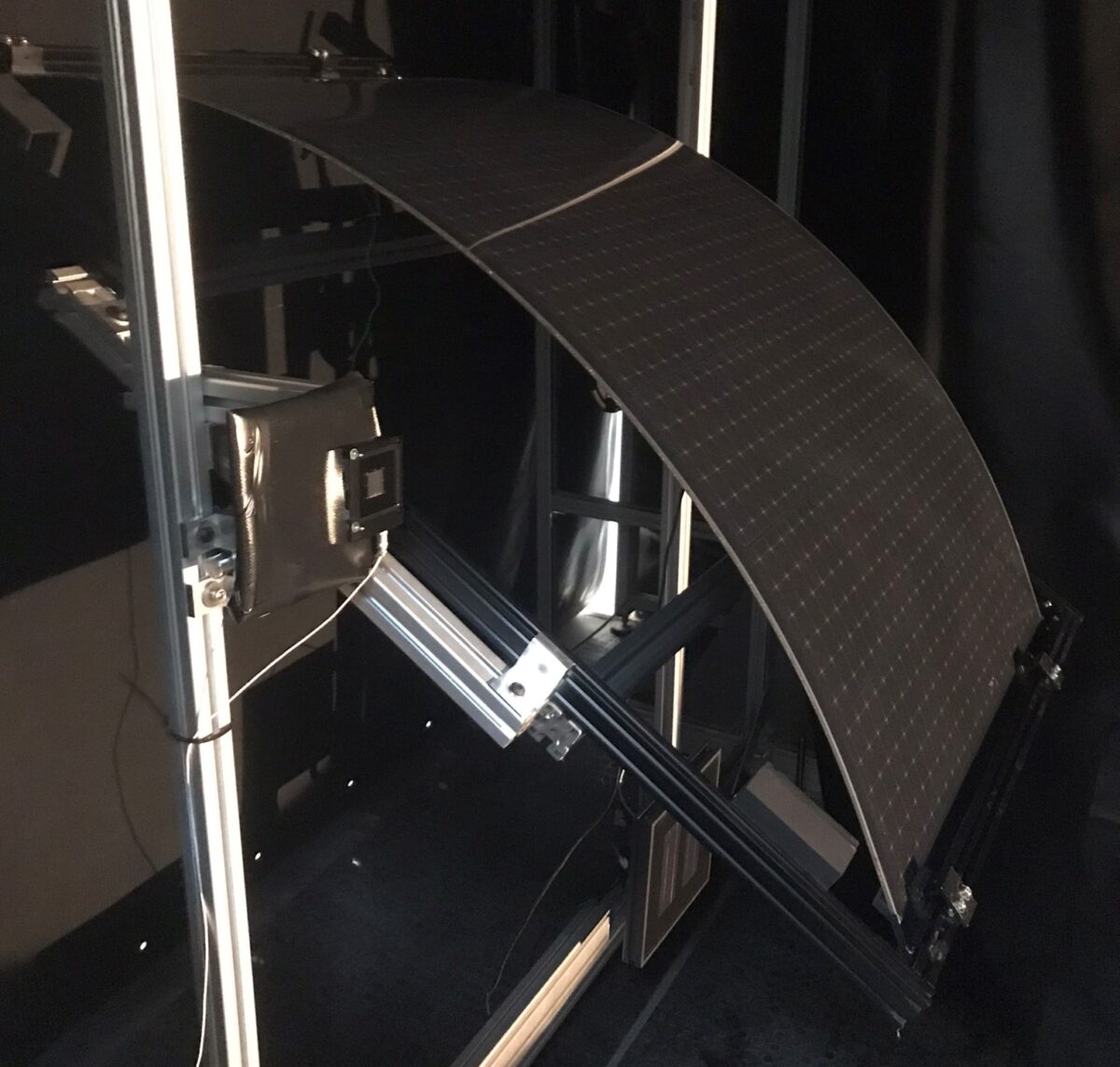

The team defined the location of the light source, the type of light source, and the length of the pulses. They chose a Helios 3198 solar simulator, originally developed to characterize concentrator photovoltaics (CPV), and adapted it to their proposed design. The light pulse power supply and electronics were modified to accommodate the slower time response of conventional silicon cells.

The setup included a black tunnel for stray light rejection, including the baffles and light trap box, and chambers. The design of the tunnel is critical to achieving an irradiance non-uniformity better than 1%, said the researchers. Light-trapping chambers closer to the lamp and baffles distributed along the tunnel are needed to effectively suppress the stray light and ensure that only the light reflected by the collimating mirror reaches the measurement plane.

The simulator is based on a multi-flash approach with the Xenon flash lamp triggered while the module is biased at a different voltage at each flash pulse, recording different pairs of current-voltage points during the pulse decay. The illumination system consists of a round collimator with a diameter of 2 m and a focal distance of 6 m, and a small toroid flash lamp of 65 mm in diameter to derive a collimated beam with a divergence of 0.3 degrees, resembling the direct normal irradiance (DNI) at outdoor conditions.

The design of the solar simulator, setup, and test results are presented in the paper “Collimated solar simulator for curved PV module characterization,” published in Solar Energy Materials and Solar Cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.