A group of researchers led by the Polymer Competence Center Leoben in Austria has investigated the cracking propensity of co-extruded backsheets based on three layers of polypropylene (PP) in an effort to assess their reintroduction in the solar module manufacturing industry.

“For a few years, we have been testing co-extruded backsheets based on polypropylene with respect to its properties, performance and reliability,” said the research's lead author, Gernot Oreski, told pv magazine. “The biggest risk for these new backsheet types is the occurrence of cracks after some years of field operation.”

In the paper “Investigation of the crack propensity of co-extruded polypropylene backsheet films for photovoltaic modules,” published in Solar Energy Materials and Solar Cells, the scientists recalled that these backsheets have been already used in the industry leading to the so-called “polyamide backsheet disaster,” which they say refer to several faulty installations developed between 2009 and 2015 across several countries with this technology.

“To my opinion, it was a really innovative idea of using co-extruded backsheets, where each layer has different requirements and therefore different fillers and additives,” Oreski said. “However, the material selection and especially the material qualification was not done thoroughly. The commonly used test protocols back then focused on the exposure to single stresses, and therefore the problematic long-term behavior of polyamide was not revealed, and so the cracking of the backsheets occurred after some years.”

“Meanwhile, new test protocols have been developed specifically to provoke such backsheet failures, and the solder bump coupon test is one of them,” he continued. “Unfortunately, this led to a reluctance on the part of the PV industry not only to use polyamides, which is understandable but also to use co-extruded backsheet films in general.”

The academics explained in the study that co-extruded PP backsheets have lower stiffness and higher flexibility than laminated backsheets. Moreover, they noted that PP backsheets exhibit low water vapor transmission rates comparable to their PET counterparts, but have high permeation rates for oxygen and acetic acid.

With a standard encapsulant, the scientists fabricated test specimens, which they called solder bump coupons, and subjected them to accelerated aging tests together with reference laminated backsheets.

Popular content

They tested five different specimens: a co-extruded backsheet based on PP; a co-extruded backsheet based on polyamide (PA); a laminated backsheet based on polyethylene (PE), polyethylene terephthalate (PET), and polyvinylidene difluoride (PVDF); a laminated backsheet based on polyvinyl fluoride (PVF) and PET; and a laminated backsheet based on fluorinated coating (fc), PET, and PVDF.

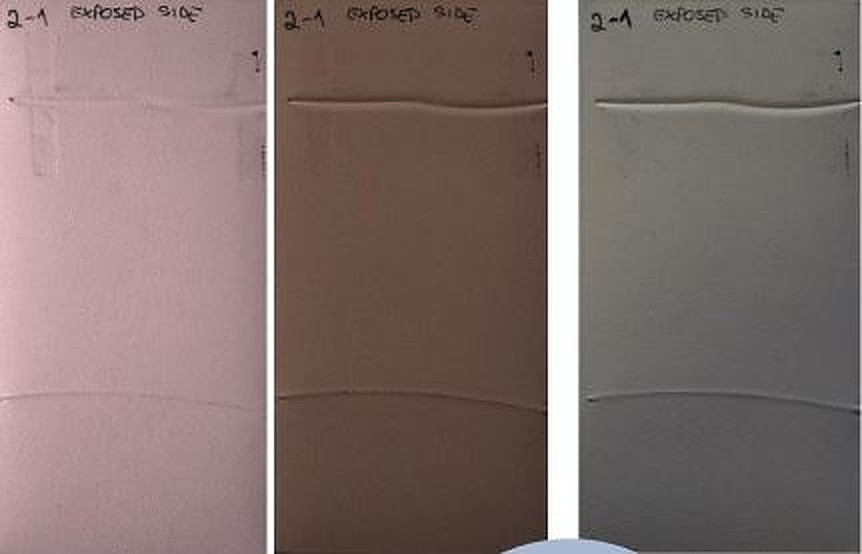

The Austrian group exposed then the specimens, after lamination, to 5 cycles consisting of 500 hours of xenon and 100 thermal cycles, with temperatures ranging from −40 C to 85 C. “Two specimens of each coupon material combination underwent the accelerated aging tests: For one sample the backsheet was directly irradiated, for the second sample the front glass was irradiated,” it explained.

The testing showed that only the second and third backsheet types listed showed severe cracking. The other three types, by contrast, did not exhibit any cracks or outer layer embrittlement.

“The results of this study confirm previously published results on the long-term stability of co-extruded backsheets based on PP, indicating an excellent stability towards temperature, humidity and UV,” the group said referring to the remarkable group of the first backsheet type. “Overall co-extruded PP back-sheets show great potential to be a valid replacement of standard PET-based backsheets in PV modules.”

The research team also includes scientists from the Austrian Research Institute for Chemistry and Technology, Silicon Austria Labs, Kioto Solar, and Borealis Polyolefine GmbH.

“Co-extrusion allows tailoring the backsheet exactly to the requirements needed for specific conditions, as the process itself is much more flexible than the lamination process,” Oreski said, referring to the real possibilities of co-extruded backsheets reentering the PV industry via the adoption of the PP material.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.