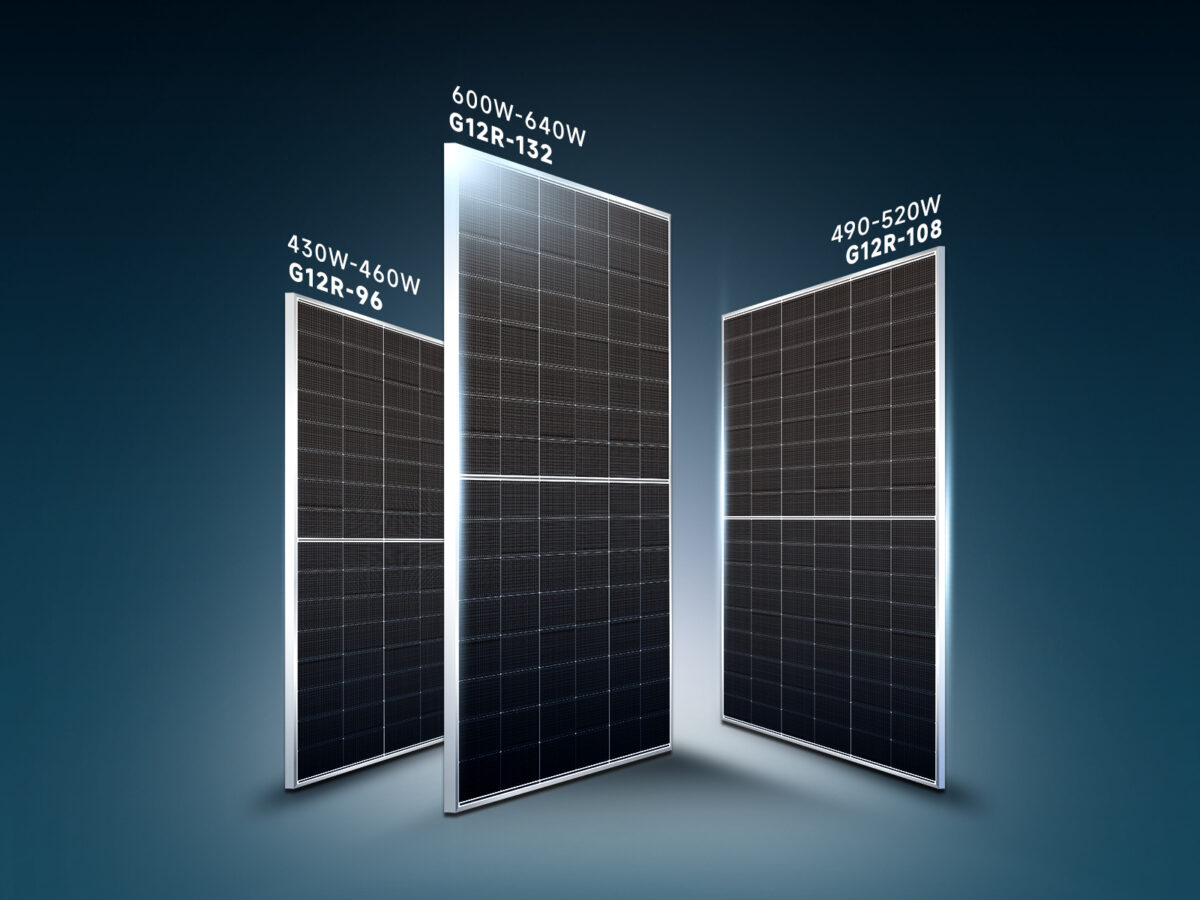

Huasun today unveiled the world’s first rectangular heterojunction solar module, the 210R, based on rectangular-cut silicon wafers that are 182 mm x 105 mm. The first batch of rectangular cells was recently produced at Huasun’s Hefei factory. The new module, called Everest, builds on the success of the company’s Himalaya module series and comes in three sizes: 430-460 W (residential), 490-520 W (commercial & industrial), and 600-640 W (utility scale).

Want to hear more from Huasun? Join the event:

Session 3 | Next generation cell and module tech

Dec 5, 12:15 pm CET, Berlin

What does life-after-PERC look like? High-efficiency n-type technologies have surged into the mainstream with TOPCon clearly the front runner. But HJT and xBC technologies are also being advanced and bringing unique value to the market. In the current oversupply market, how will high-efficiency technologies compete, and what is the pathway for future cost reductions? Furthermore, can these next-generation technologies overcome material supply challenges? More info and free registration.

Traditionally, silicon wafers are cut into squares and then processed into solar cells. Solar module manufacturers increasingly use half-cells in modules because it reduces resistance and power loss, while increasing efficiency and yield. However, cutting processed square solar cells in half presents risks of damage and breakage. By starting out with rectangular silicon wafers and then processing those into HJT cells, Huasun is reducing these risks, as well as eliminating the equipment necessary to cut each individual processed cell in half.

The 210R module, featuring double-glass structure, incorporates an advanced EVA with PIB edge sealant. This combination enhances its waterproof capability and ensures exceptional reliability. It features a 110 μm silicon wafer, which the manufacturer plans to reduce to 90 μm in the future. Huasun says the advanced Everest series modules have a greater resistance to hotspots and high reliability, with an expected ≥88% power retention rate after 30 years. The company says the new module’s temperature coefficient is -0.26%/°C and that it has a bifaciality of over 85%, with a world leading module power of 640 W and efficiency of 23.7% in mass production. The 210R cells could achieve an average efficiency of 25.5% in mass production.

More from our partners

According to Huasun data, compared with a 600 W TOPCon module, the switch to the rectangular 630 W HJT module, as well as the application of silver-plated copper, will reduce balance of system (BOS) costs by 1.7% and the levelized cost of energy (LCOE) by 2.6%. The increased yield and lower costs of the rectangular model are projected to increase the internal rate of return (IRR) on a project by 3.9%.

In addition to reducing the cost, Huasun is also lowering the carbon footprint of its HJT modules. In July 2023, the manufacturer achieved 366.12 g/W CO2 equivalent, and it anticipates reaching 300 g/W in the near future. Additionally, the 210R module series comes with a 15-year product warranty and a 30-year performance warranty.

The utility scale size module in Huasun’s Everest series is available in the “golden size” – 2382 mm x 1134 mm – which is rapidly becoming the standard size for modules in the industry and was recently agreed upon by the China Photovoltaic Industry Association and multiple manufacturers. Huasun is manufacturing the Everest modules at its facilities in Hefei, Wuxi, and Xuancheng with an initial annual capacity of 12 GW.

Since its establishment, Huasun has dedicated itself to positioning heterojunction as a mainstream solar cell technology in the n-type era through consistent advances in industrialization and commercialization. With the launch of the Everest module series, Huasun says its goal is to be at the forefront of HJT’s advance into the “R” era.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

This is impressive