An international group of researchers led by Saudi Arabia's King Abdullah University of Science and Technology (KAUST) has fabricated a perovskite-silicon tandem solar cell with a top inverted perovskite cell relying on an electron transport layer (ETL) made of thermally evaporated buckminsterfullerene (C60).

Inverted perovskite cells have a device structure known as “p-i-n”, in which hole-selective contact p is at the bottom of intrinsic perovskite layer i with electron transport layer n at the top. Conventional halide perovskite cells have the same structure but reversed – a “n-i-p” layout. In n-i-p architecture, the solar cell is illuminated through the electron-transport layer (ETL) side; in the p-i-n structure, it is illuminated through the hole‐transport layer (HTL) surface.

“For scale-up, repeatable processes are of extreme importance,” the research's corresponding author, Stefaan De Wolf, told pv magazine. “Here, we show that for evaporated C60, which is the electron-selective contact material in all high-efficiency tandems, such repeatability may be an issue, depending on the quality of the source material. Using sublimated C60 resolves this issue.”

In the paper “Sublimed C60 for efficient and repeatable perovskite-based solar cells,” published in nature communications, the research team explained that C60 is common as the preferred material for ETLs in inverted solar cells, due to its small conduction band offset and large valence band offset with respect to the perovskite absorber, which in turn is beneficial to the cell electron-extraction and hole-blocking properties.

The poor solubility of this material, however, requires the use of solution-based methods such as spin-coating, spray, or blade coating, although the preferred process to ensure minimizing parasitic optical absorption caused by C60 would be thermal evaporation.

Popular content

“Our findings reveal that, as a result of the heating and cooling cycles of the source material during multiple evaporation cycles, C60 undergoes a conversion into higher molecular weight structures through the fusion of C60 molecules,” the academics explained. “This transformation leads to modifications in the electronic properties of the fullerene, detrimentally affecting device performance. However, we show that further purification of as-received C60 can help to avoid these issues, and device performance remains unaffected even after repeated deposition cycles.”

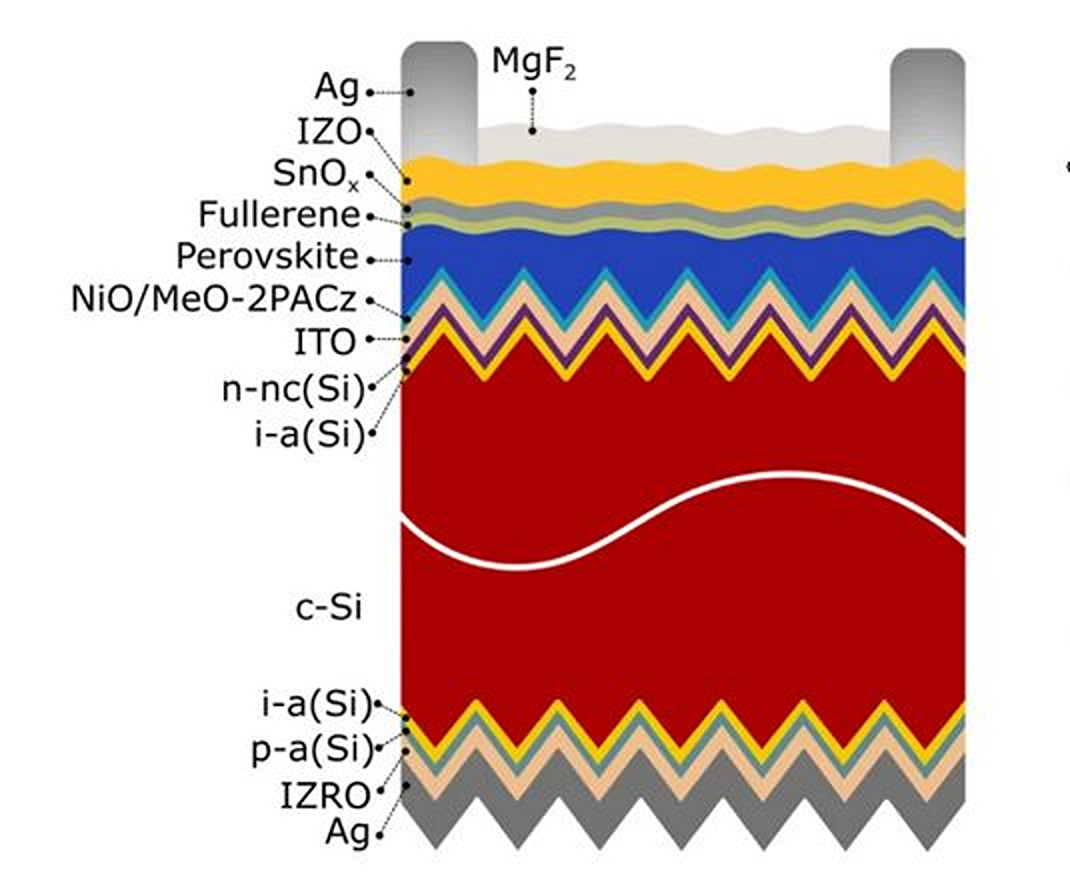

Through this process, the group built a cell based on an indium tin oxide (ITO) substrate, a hole transport layer (HTL) made of nickel(II) oxide (NiOx) and phosphonic acid called methyl-substituted carbazole (Me-4PACz), a perovskite absorber, the C60 ETL, a bathocuproine (BCP) buffer layer, and a silver (Ag) metal contact.

This cell was then stacked as the top device in a perovskite-silicon tandem solar cell incorporating an anti-reflective coating based on magnesium fluoride (MgF2). Tested under standard illumination conditions, this tandem device achieved a power conversion efficiency of 30.90%, with the results being confirmed by Fraunhofer ISE CalLab.

The scientists believe these efficiency levels are encouraging and said commercial PV modules with C60 contacts are already in sight in the industry. “In addition to the potential of using sublimed C60, our work provides valuable guidance for the preparation of fullerenes that are more suitable, particularly oxygen-free, for commercial perovskite-based solar cell processing with high yield.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Ok

I’m an Emeritus scientist in Glasses and Ceramics technology want to propose new patented product for slabs and tiles manufacturing for alternative to Tesla’s roof solar panels. It’s cheaper and ecologically friendly then current solutions.