Scientists at Monash University Malaysia have looked at how graphene and graphene derivatives could be used as materials to reduce the operating temperature of solar panels.

In an in-depth review published in Renewable and Sustainable Energy Reviews, the researchers explained that graphene has attracted the interest of the scientific community as a medium to enhance heat transfers in cooling systems since 2004.

When used for PV cooling applications, graphene can be used in different ways. For example, it can be used as a selective absorber coating or embedding it into a working fluid as a nanofluid. Graphene nanoparticles can also be added to thermal interface materials (TIMs) or phase change materials (PCMs) used for solar module cooling.

The group divided all graphene technologies applied to PV into two categories – passive and active cooling.

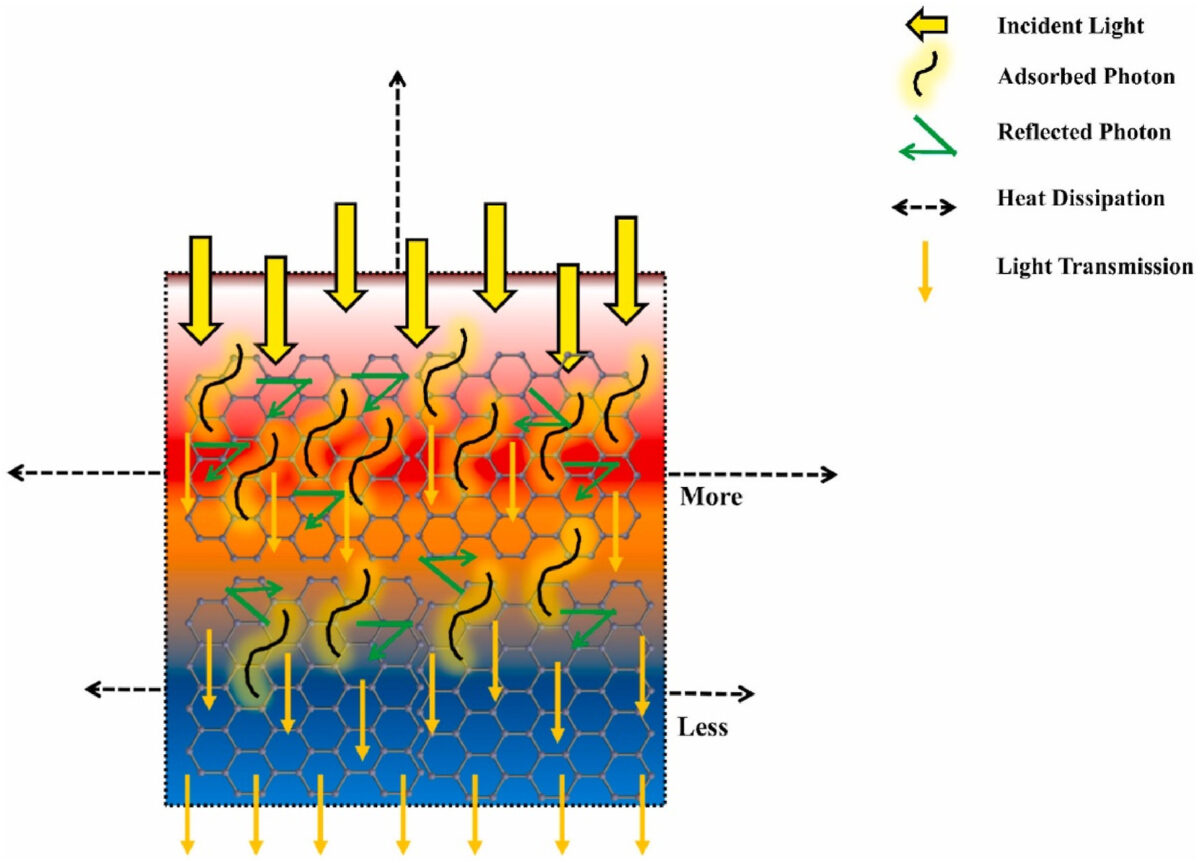

The first category was split into pre-illumination and post-illumination techniques. The latter involves all methods that use a heat receiver to dissipate heat generated from solar cells, while the former includes all approaches that decompose the sun spectrum before it reaches the PV cells.

The pre-illumination category is represented by all types of graphene-coated neutral density (GCND) filters used as selective absorber coating.

“The application of the GCND filter as a pre-illumination passive cooling technique is highly advantageous, particularly in cooling CPV systems,” the academics said. “This pre-illumination cooling technique attenuates the solar radiation before it reaches the PV panel, thus reducing the amount of heat generated at the PV panel.”

They also recommended using GCND filters only for small-scale domestic applications, due to their high costs.

Popular content

“Rather than coating graphene across the entire substrate, focusing the graphene coating specifically at the focal spot area could contribute to reducing coating costs,” they added.

As for the post-illumination category, the list includes using graphene as a thermally conductive filler in TIMs and PCMs.

“While both TIM and PCM present advantages and disadvantages of their own, there is no universal answer to whether TIM or PCM in passive cooling of PV panels is better,” the group said.

The active cooling category includes all techniques based on graphene nanofluids configured as working fluids. These techniques, like all active cooling methods, require the construction of pumps and pipes to circulate the nanofluid around the modules, which the scientists said raises significantly production costs.

“The challenge of using graphene nanofluid is the costly and complex fabrication process, which prevents graphene nanofluid from being adopted in common industry practice,” said the researchers.

The group acknowledged that more research will be required to reduce costs and improve cooling efficiency. The researchers also said that synthesizing graphene nanofluid and hybridizing graphene nanofluid and graphene-enhanced PCMs are the main technical challenges to overcome.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.