An international research team has designed a novel cooling system for PV modules involving a phase change material (PCM), heat sink fins, and water. The experimental system utilizes passive cooling, as it uses the latent heat of fusion of PCM and the latent heat of evaporation of water.

PCMs can absorb, store, and release large amounts of latent heat over defined temperature ranges. They have often been used at the research level for PV module cooling and the storage of heat.

“The drawback of the PV-PCM system is mitigated with the use of heat sink fins, which extract the heat efficiently from PCM. Meanwhile, water is still utilized to accelerate the heat transfer process via energy storage and evaporation,” said the researchers.

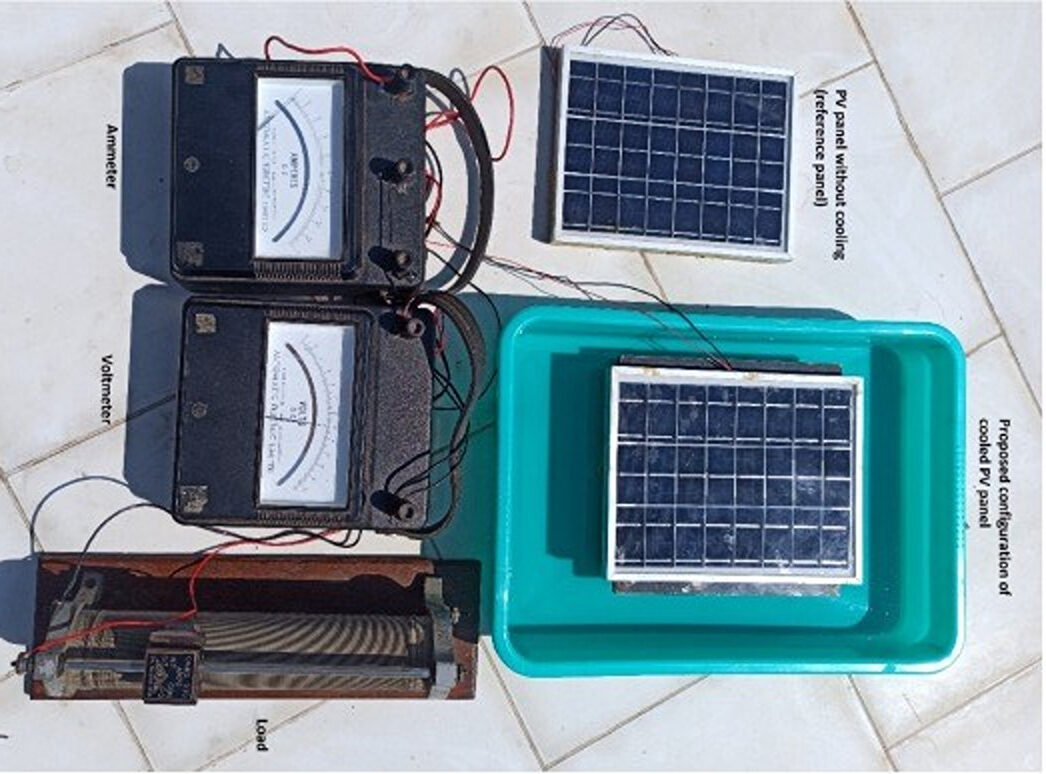

Presented in the paper “An experimental investigation on coalescing the potentiality of PCM, fins and water to achieve sturdy cooling effect on PV panels,” published in Applied Energy, the system prototype consists of a 5 W polycrystalline PV panel embedded with HS 29 PCM packed to around 0.02 m thickness.

The HS 29 PCM, which has a melting temperature of 29 C, was chosen based on the location and system thermal characteristics. A flat plate of heat sink fins, measuring 21 cm × 21 cm, is adhered to the PCM bottom surface. The system is placed inside a plastic container, with 3.3 liters of water covering the fins.

That system was tested against a reference 5 W polycrystalline PV panel without any cooling. The experiment was done in the southern Indian city of Madurai in early October 2020. Electrical, thermal, and efficiency characteristics were measured daily from 9 a.m. to 5:30 p.m. at 30-minute intervals. Using a set of equations, some of the results were scaled up for a large-scale 1 MW PV system.

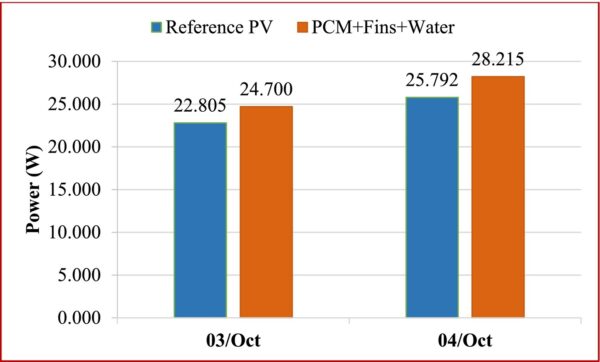

According to the research team, the per-day power output in W of the proposed configuration was 8.12% and 9.39% higher than the reference panel. Also, the maximum power obtained from the cooled panel was 20.25% higher than the reference panel.

Popular content

“The output power of the reference PV panel ranges from 2.579 W to 3.062 W on October 3 while it ranges from 2.785 W to 3.538 W on October 4,” the researchers noted. “On the other hand, the output power of the proposed configuration ranges from 2.538 W to 3.336 W on October 3 while it ranges from 2.880 W to 3.864 W on October 4.”

Image: The University of Queensland, Applied Energy, CC BY 4.0 DEED

On average, the novel system helped reduce the panel temperature by 10.14 C. The highest temperature difference, 16.7 C, was obtained at 10:30 a.m. on October 4. When scaled up to a 1 MW plant, the scientists found the drop in temperature to extend its lifetime from 25 years to 31.

“The proposed PV cooling scheme shows a 9.4% additional CO2 reduction compared to normal solar PV,” the researchers added. “A sum of 2130.578 Tonnes of CO2 reduction can be achieved using a 1 MW solar PV with the proposed cooling technique.” They also added that the cooling strategy renders 9.4% energy saving per day, which, scaling to a large plant, means 366.5 MW per year.

Regarding efficiency in relative terms, the researchers found the proposed system to enhance it by 20.3% on the first day and 13% on the second day. However, the average efficiency enhancement ranged from 0.78% to 1.08%.

“The designed cooling system can target residential solar PV panels,” the academics concluded. “This pilot study can also be provisioned with a heat collecting system from water to form a PV-T system. Further, this research paves the way for exploring the feasibility of employing this cooling approach in floating panels since they float on still-water bodies.”

The research group comprises scientists from Australia’s University of Queensland, USA’s University of California Los Angeles (UCLA), and India’s Thiagarajar College of Engineering, Madurai.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.