A group of researchers led by the Wuhan University of Technology fabricated a carbon-based perovskite solar cell that uses a playdough-like graphite (PG) putty as an electrode.

“The playdough-like carbon electrode is the latest and best carbon electrode technique available in our lab,” the research's lead author, Junyan Xiao, told pv magazine. “Top electrodes can be realized with this convenient, effective and damage-free contact between the functional layers.”

The research group explained that the PG features the deformable property of carbon paste and the solvent-free property of carbon film, which were both used in previous research on carbon-based perovskite cells, noting that carbon electrodes offer almost the same efficiency as gold (Au) electrodes, while also providing higher stability.

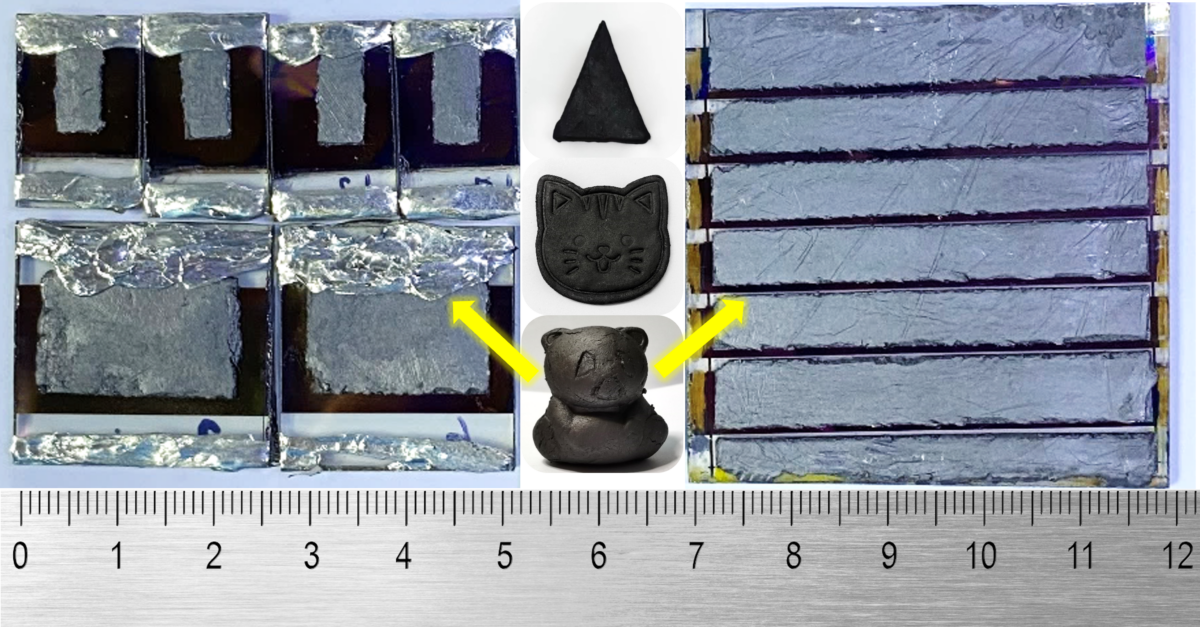

The scientists designed the cell with a substrate made of fluorine-doped tin oxide (FTO), an electron transport layer (ETL) based on yttrium-doped tin oxide (SnO2), a perovskite absorber, a hole transport layer (HTL) based on Spiro-OMeTAD, and the PG electrode. “PG slices with suitable size were positioned onto the FTO/SnO2/perovskite/spiro-OMeTAD semi-device by roll pressing or plate-to-plate lamination pressing (1 MPa) at room temperature,” they stressed.

With this architecture, the group constructed a cell with an active surface of 0.15 cm2. Tested under standard conditions, this device achieved a power conversion efficiency of 20.29%, an open-circuit voltage of 1.13 V, a short-circuit current of 22.29 mA·cm−2, and a fill factor of 81%. By way of comparison, a reference cell with an Au metal contact achieved an efficiency of 21.04%, an open-circuit voltage of 1.13 V, a short-circuit current of 22.27 mA·cm−2, and a fill factor of 81%.

Popular content

However, the efficiency of the Au electrode cell decreased below 40% over 300 h, while the PG electrode cell was able to retain 96.3% of the initial efficiency after 1,300 h. “It is believed that the drying-hygroscopic dynamic balance of sorbitol can avoid moisture penetration into the perovskite layer, and help to form a better HTL/PG interface during the long time storage,” the academics explained. “Also, PG-L electrode has good mechanical stability in the device and can easily withstand the tape test under 5 N pulling force.”

Using the novel carbon-based cell, the group fabricated a perovskite solar module on FTO substrates measuring 5 cm × 5 cm. It used P1, P2, and P3 laser scribing for building the monolithic interconnections that add voltages between cells in modules. The panel achieved an efficiency of 16.01%, an open-circuit voltage of 6.58 V, a short-circuit current of 3.65 mA·cm−2, and a fill factor of 67%, a performance that was described as “pretty outstanding.”

“PG material and its process method integrate the advantages of printable electrode from low-temperature carbon paste and transferring electrode from prefabricated carbon film,” the researchers concluded. “Despite the shortcomings of PG electrode in terms of optical reflection and module conductivity relative to Au electrode, the low material cost, environmental sustainability, simple process, and easy scalability of the PG electrode make this technique highly promising for the industrialization of carbon-based perovskite solar cells.

The novel perovskite solar cell and module concept was described in the study “Playdough-like carbon electrode: A promising strategy for high efficiency perovskite solar cells and modules,” published in eScience.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.