Perovskite solar cells, and tandem structures combining them with silicon, have been a subject of much interest among PV researchers in recent years. And their achievements with the technology are impressive enough for the industry now to be taking serious notice.

Much of the hype around perovskites comes from the potential for low-cost manufacturing, however, while the technology is well on its way to commercial-scale manufacturing, many approaches that have been successful in the lab remain largely untested at scale. And this, warns a group of scientists led by the University of New South Wales, might lead to “unexpectedly high costs hidden in the detail.”

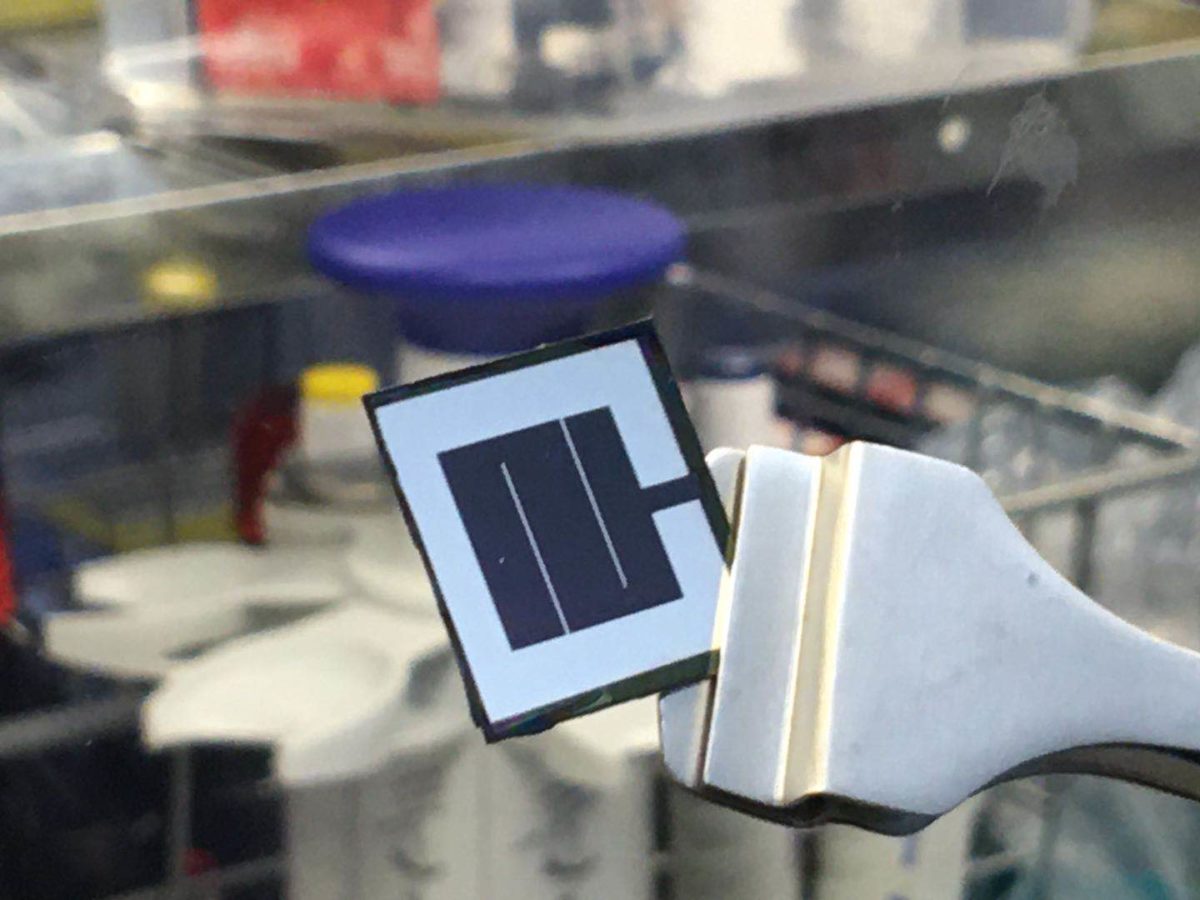

Identifying these unexpected costs is the focus of the group’s latest research. They first calculated a cost vs. efficiency trade-off, to determine price ranges where tandem cells could be competitive with current standard crystalline silicon. Then the group conducted detailed cost analyses for six previously reported tandem cell structures, incorporating both standard PERC silicon and heterojunction technologies for the bottom cell, and a seventh hypothetical low-cost cell structure. The analysis is available in the paper A bottom-up cost analysis of silicon-perovskite tandem photovoltaics, published in Progress in Photovoltaics.

Material costs

One key conclusion of this study is that SPIRO-ometad and other similar materials used as a hole transport layer in perovskite cells are one area where much more work is needed. Even calculating in a ten-fold cost reduction in the material’s cost due to economies of scale, this still represents the biggest chunk of the perovskite cell cost. The group recommends a number of other potential materials to investigate as replacements, though noting “It is possible that the actual cost reduction of scaling up SPIRO production is much greater than that assumed. However, this depends on overcoming its ‘tedious synthesis process and low product yields’ and cannot be guaranteed.”

More efficient utilization of other materials, and the replacement of spin coating processes that tend to waste more of them, were noted as other potential areas for cost reduction, as well as the fact that many of the best performing tandems fabricated to date were based on more expensive ‘float zone’ silicon – understandable when you’re trying to set a new efficiency record, but less practical for low-cost production.

The hypothetical lowest cost cell analyzed was calculated to cost around $1.50 per cell to produce. According to the group’s calculations, this cell would need to have at least 25% efficiency to be competitive on levelized cost of electricity with an industry-standard PERC cell.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Well done, I need a much clearer explanation if you don’t mind. Throw more light please!!

All fine now. I’ve read through the analysis in the paper, thanks for dropping the link.