Researchers at Germany's Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) have fabricated a perovskite-silicon tandem solar cell that relies on a bottom PV device with a TOPCon design and high passivation quality.

“We have built the first perovskite-silicon tandem device that integrates a TOPCon bottom cell with industry‑standard textured front side, achieving an efficiency above 30%,” the research's lead author, Mario Hanser, told pv magazine. “Demonstrating that the TOPCon2 cell design and its lean process flow are compatible with perovskite/silicon tandem integration marks a key step towards cost-efficient industrial tandem solar cell production.”

In the paper “Fully-Textured Perovskite/Silicon Tandem Solar Cells Exceeding 30% Efficiency on Both Side Tunnel Oxide Passivating Contacted Bottom Cells,” which was recently published in RRL Solar, Hanser and his colleagues explained that the proposed bottom cell relies on two full-area tunnel oxide passivating contacts developed through single-sided in situ doped amorphous silicon layer depositions.

This cell configuration features a conventional micrometer-scale random pyramid texture on the front side, which the scientists described as standard in silicon production lines and as providing higher shunt resistivity. They also stressed that local shunts in the TOPCon emitter are identified as a main challenge for the TOPCon2 solar cell design, when compared to the heterojunction (HJT) architecture, as they are more frequent in n-type wafers where the p-TOPCon layer at the rear surface forms the pn-junction.

The scientists used plasma-enhanced chemical vapor deposition (PECVD) for the hydrogenated deposition of silicon nitride (SiNy) in wafers with a planar p-TOPCon rear side and the deposition of aluminum oxide and silicon nitride (AlOx-SiNy), with both cell sides being annealed in a furnace at 650 C.

“On wafers with a textured rear side, the rear metallization consists of a layer stack made with indium tin oxide (ITO) and silver (Ag) , while planar p-TOPCon rear sides are directly contacted with Ag,” they specified, noting that a hotplate curing anneal was used after the sputter deposition of ITO to prevent damage.

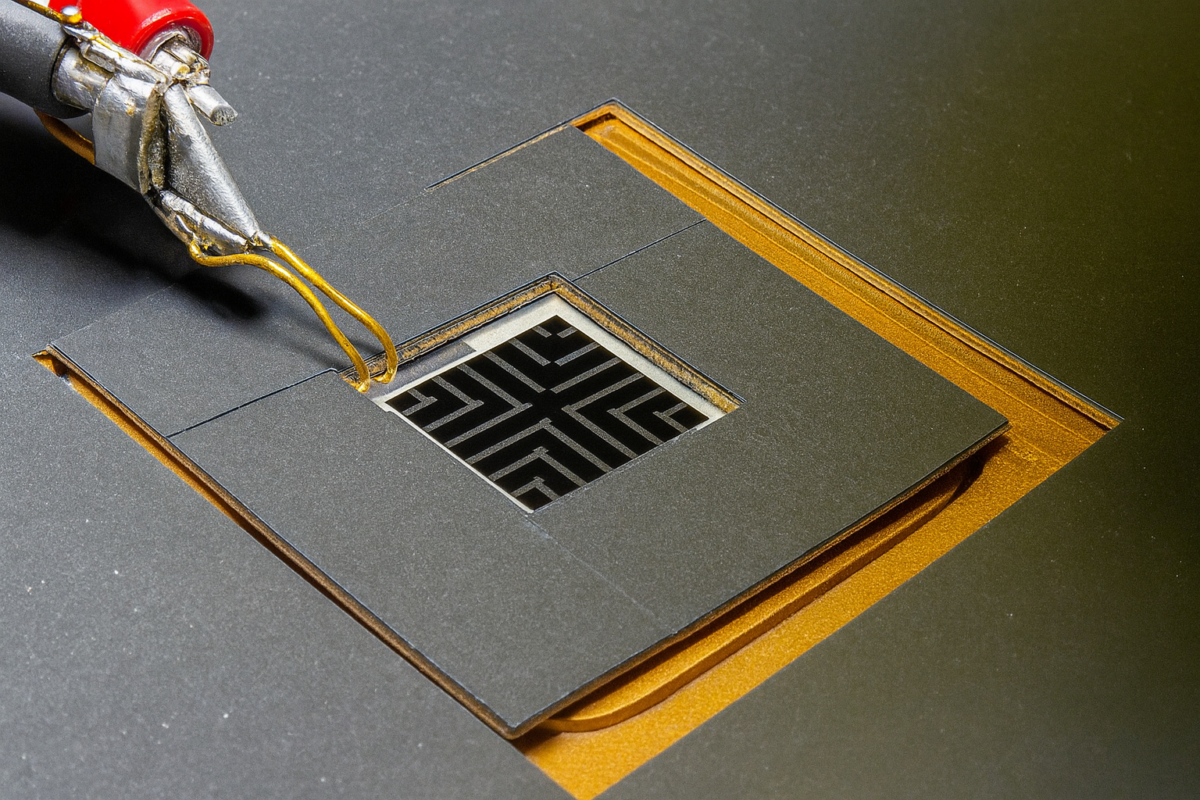

Image: Fraunhofer ISE

The bottom TOPCon cell was then integrated in a tandem device with a top perovskite device built with an ITO substrate, a hole transport layer (HTL) made of a phosphonic acid called methyl-substituted carbazole (Me-4PACz), a perovskite absorber, an electron transport layer (ETL) relying on buckminsterfullerene (C60), a tin oxide (SnOx) buffer layer, an anti-reflective coating based on magnesium fluoride (MgF2), and an Ag metal contact.

Tested under standard illumination conditions, the tandem cell achieved a power conversion efficiency of 30.6%, an open-circuit voltage of 1,930 mV, a short-circuit current density of 19.8 mA cm2, and a fill factor of 80%, with the tests showing the cell achieved a performance comparable to that of a benchmark tandem cell based on a bottom HJT device.

“This clearly indicates that top cell formation and top cell performance are not affected by the type of silicon substrate, SHJ or TOPCon,” the scientists emphasized. “This result is expected to be transferable to other bottom cell concepts featuring a textured n-TOPCon front contact, for example, interdigitated TOPCon (iTOPcon) solar cells.”

Looking forward, the scientists plan to transfer the proposed cell design to industrially relevant Czochralski (CZ) material.

Other researchers at the Fraunhofer ISE have recently applied, for the first time, the so-called mask-and-plate front-metallization approach to the development of perovskite-silicon tandem solar cells. They fabricated a 1.21 cm² tandem solar cell featuring a heterojunction bottom device. The cell achieved an efficiency of 19.35%, reportedly the highest value reached to date for this cell type using galvanic front metallization.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.