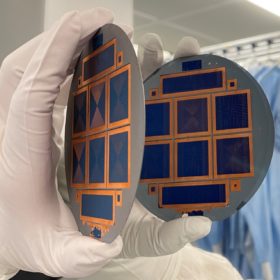

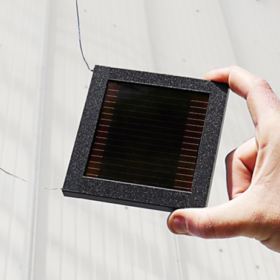

Copper-plated heterojunction solar cell with 22.1% efficiency, 0.99 bifaciality factor

Built by a Dutch-Chinese research team, the cell is relying on a new type of hybrid-shaped Cu finger consisting of a rectangular bottom part and a round top part, which was integrated into the cell through a 2-step electrochemical deposition process. The Cu-plated device outperformed both optically and electrically a reference cell fabricated via screen printing.

Phono Solar introduces 560W TOPCon solar module with 21.72% efficiency

The panel is part of the company’s new TOPCon module series, which also includes a 430W product with an efficiency of 21.99%.

Solar-powered self compacting garbage can

The city government of Florence, in Italy, is installing solar-powered, self-compacting garbage cans that are claimed to reduce emptying operations by 94% compared to traditional bins. The devices were provided by Korean manufacturer Ecube Labs.

‘This is wartime and wartime requires war economy measures’

In a chat with pv magazine, Christian Breyer – Professor of Solar Economy at Finland’s Lappeenranta University of Technology – explains which consequences the war in Ukraine may have on Europe’s energy landscape. According to him, only an unprecedented development of renewable energies, heat pumps and storage may help address the current energy crisis.

Kaneka raises solar module prices by 20%

The Japanese manufacturer blames increasing wafer prices and logistics costs for its decision.

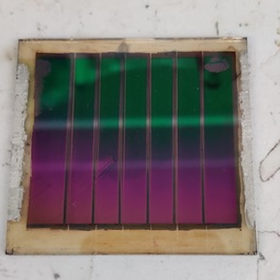

Semi-transparent perovskite solar cell with 13% efficiency, 27% transparency

Developed for applications in BIPV, vehicle-integrated solar and smart glasses, the solar cell was built with an ultra-thin, semi-transparent, triple-cation perovskite film and gold nanorods (Au NRs). The device achieved an open-circuit voltage of 1097.1mV, a short-circuit current of 17.11mA/cm2 and a fill factor of 73.12%.

Scatec provides update on operations in Ukraine

The Norwegian renewable energy developer said its solar power plants are still intact and can be operated remotely. It is currently assisting its Ukrainian employees by offering transportation, accommodation and other immediate support.

Testing different PV module brands in photovoltaic-thermal architectures

Solar modules from Trina Solar, Canadian Solar, and Felicity Solar were tested in a prototype of a photovoltaic-thermal collector that uses excess heat from the PV elements to heat water. The system uses a thermally insulated helical coil heat exchanger to recover panel heat and a solenoid valve to allow water recirculation when the temperature below the PV module rises significantly.

Solar module anti-soiling coating for retrofit application

Dutch company Rads Global Business has developed an anti-soiling coating for solar PV modules that are at least two years old. The new product is claimed to increase power yield by up to 7% and to have a payback time of 2.5 to four years depending on the dust level of the site.

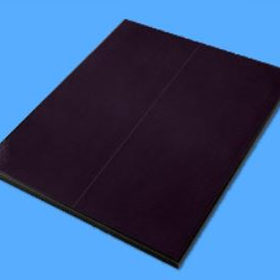

Mini perovskite solar module with 40 sq cm aperture area, 17% efficiency

The 19.2%-efficient perovskite cells used in the module rely on an electron layer based on tin oxide that was deposited via chemical bath deposition. This technique, according to the device’s creators, has made it possible to have a relatively small drop in efficiency from small cells to the 40cm2 module.