The weekend read: One side or two

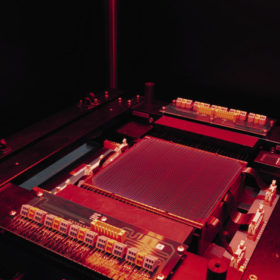

Bifacial modules are here to stay. But even as manufacturers commit further capacities to two-sided module production spanning a whole range of technologies, there are still challenges to overcome, to fulfill predictions that bifacial will represent almost 40% of all modules produced inside the next decade. Flash testing conducted at the end of cell and module production presents one of these, and there is plenty of debate among equipment suppliers as to how this manufacturing stage should treat bifacial cells and modules.

Shortage of polysilicon for mono-Si wafers lifts prices

Analysts have observed rising demand amid rumors of stock shortages. Meanwhile, the price of mono cells fell further, although not far enough as far as the big beasts of the PERC module jungle are concerned.

Longi to spend $349m on new 5 GW module fab in Taizhou

The world’s number one mono silicon module manufacturer will add another 5 GW to its annual panel production capacity in 2020 as it pursues 16 GW of output this year and 25 GW next year.

Solid (state) plans announced by imec

Belgian research institute imec this week said it has set a performance record of 400 watt-hours per liter – at a charge rate of 0.5 – for a solid state lithium metal battery. The institute says it is working with the University of Hasselt to scale up production of solid state cells on a pilot line in Belgium.

Comtec sells slice of EV unit to online gaming company The9

The Nasdaq-listed game developer will offer shares in return for a 9.9% stake in the Chinese mono solar manufacturer’s Kexin electric vehicle and storage business.

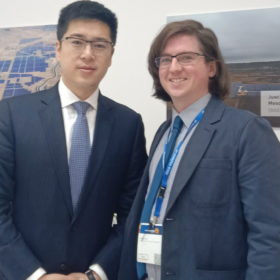

Well it’s Swan for the money…

This year JinkoSolar launched its bifacial Swan module, one of the first to feature a transparent Tedlar backsheet made by DuPont. pv magazine had the chance to catch up with Gener Miao, JinkoSolar VP for global sales and marketing for an update on the module’s innovations, and on how the company sees solar markets this year.

GCL-Poly completes shares placement to help pay down debts

Company stock diluted more than 8% to generate gross proceeds of $87 million as the company continues its policy of expansion at a breakneck rate.

Sunseap ready to install 100 MW in Taiwan

In pursuit of its ambitious 2025 solar goal of 20 GW of installed capacity, Taiwan continues to be an attractive market for foreign companies and investors.

Xinyi revises plans for shares placement

The glass maker is set to issue fewer shares – at a higher value – in its solar glass subsidiary as it aims to generate funds for two new PV glass production lines in China.

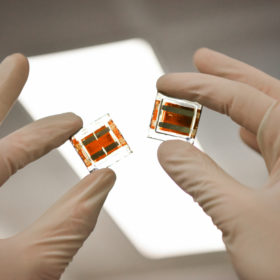

Copper iodide, another option to stabilize perovskite cells

A research team from Russia’s institutes NUST MISIS and IPCE RAS, and Italy’s University of Rome Tor Vergata, have applied an additional layer of p-type copper iodide semiconductor between perovskite and the hole-transport NiO layer of the cell. According to the scientists, this inorganic material is more accessible and easy-to-use.