Plans for EV battery raw material supply in Iberia

The partners behind a JV aiming to develop a lithium conversion factory in Portugal say Iberia could supply enough geological feedstock spodumene to produce 700,000 EV batteries per year, starting in 2026.

The Hydrogen Stream: Longi wants to reach electrolyzer capacity of 2 GW by 2023

Elsewhere, Air Products is planning to build a 2 GW electrolysis plant in Saudi Arabia and Protium is deploying its first 100 kW electrolyzer in the U.K.

Shell buys US solar and storage company Savion

The transaction, for which Shell did not reveal the purchase price, will see the energy company pick up a U.S. project development pipeline which reportedly runs to more than 18 GW of solar generation and energy storage capacity across 26 states.

Scatec brings containerized solar-plus-storage system to Cameroon

Two projects in the northern region of the African nation are set to bring 36 MW of solar and 20 MW/19 MWh of storage online, with the first facilities due to start generating within days.

Analyst predicts 2030 bidding war for dead EV batteries

A lack of end-of-life batteries this decade is likely to play into the hands of Chinese recyclers located near most of the world’s production facilities, according to analyst WoodMac, but might at least help rebalance the current situation in which new products are cheaper than recycled ones.

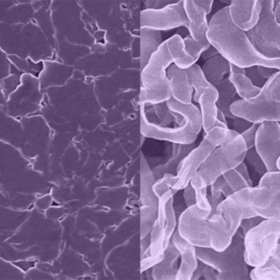

Sodium battery research tackles formation of dendrites

Sodium batteries, an increasingly competitive area of research, have emerged as a low-cost, lithium-free energy storage alternative based on abundant, more environmentally friendly materials. A pair of new research papers addresses some of the remaining hurdles to widespread adoption, such as the formation of dendrites on the anode.

Grid stability and 100% renewables

New research from Stanford University professor Mark Jacobson seeks to remove any doubts about grid stability in a world powered entirely by renewable energy. The latest study models 100% wind water and solar powered grids across the United States, finding no risk of blackouts in any region and also broad benefits in cost reduction, job creation and land use.

Brazil and Chile could lead charge to affordable green hydrogen

Falling electrolyzer costs driven by economies of scale, increased automation of production and the modularity of such systems will bring green hydrogen to a competitive cost with its fossil-fuel powered variants in a dozen markets by 2030, according to WoodMac.

Fast charging for lithium-ion batteries needs a fix

Scientists in the United States placed fast charging for lithium-ion batteries under the microscope, finding that charging at higher rates can quickly damage the structure of a graphite anode, causing capacity loss even after a small number of cycles. By identifying the mechanisms causing this performance loss, the group can help point future research in the right direction.

Narrowing down a million molecules for the optimal flow battery

Scientists in the United States turned to artificial intelligence to speed up their search for new materials for use in a flow battery. The group developed a machine learning algorithm that could search a dataset of potential materials and identify those with the ideal balance of different characteristics that make it suitable for use in a flow batteries. The group says its algorithm could be applied to other battery technologies, and even in other fields.