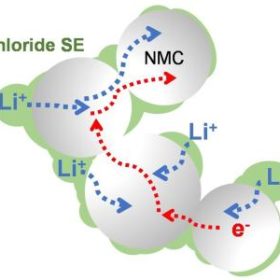

Solid-state lithium-ion battery with capacity retention of over 4mAh/sq cm

Researchers from the University of Waterloo, Canada, have developed a new solid chloride electrolyte that swaps out half of the indium for scandium and offers several important advantages, such as high voltage operation.

Underwriters Laboratories to assess Redflow’s redox flow batteries

Underwriters Laboratories, a US non-profit standards development organization, will carry out research into the operating and safety profile of Redflow’s redox flow batteries under nominal and off-nominal conditions.

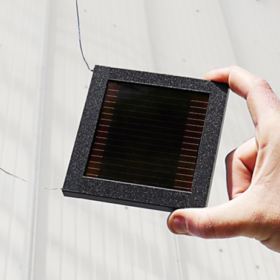

Solar module anti-soiling coating for retrofit application

Dutch company Rads Global Business has developed an anti-soiling coating for solar PV modules that are at least two years old. The new product is claimed to increase power yield by up to 7% and to have a payback time of 2.5 to four years depending on the dust level of the site.

Green hydrogen, blue hydrogen to reach cost parity in Europe by 2030

The direct coupling of electrolyzers with PV and wind power systems will become the cheapest forms of energy in many parts of Europe, according to Aurora Energy Research.

‘The major solar players will shift from PERC to TOPCon’

US analyst Clean Energy Associates made some notable predictions in its Q4 survey of the world solar manufacturing market, including echoing predictions made elsewhere that the new polysilicon production capacity coming online now will help arrest the spike in solar panel prices.

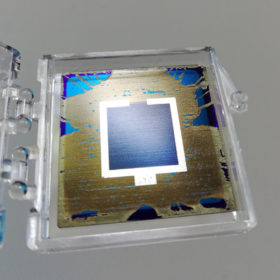

Mini perovskite solar module with 40 sq cm aperture area, 17% efficiency

The 19.2%-efficient perovskite cells used in the module rely on an electron layer based on tin oxide that was deposited via chemical bath deposition. This technique, according to the device’s creators, has made it possible to have a relatively small drop in efficiency from small cells to the 40cm2 module.

Wireless EV charging coming soon to US market

WiTricity has unveiled plans to develop wireless charging stations for select electric vehicle models.

The Hydrogen Stream: Airbus plans flight test with direct combustion engine fueled by hydrogen

Elsewhere, Chinese researchers have synthesized ultrafine Pd100-xCux nanodot-modified TiO2 photocatalysts that display optimized energy barrier for interfacial hydrogen desertion, which reportedly exhibits excellent H2-evolution activity and stability, and Mitsubishi Heavy Industries has presented its plans to establish the Takasago Hydrogen Park, calling it the world’s first center for validation of hydrogen-related technologies, from hydrogen production to power generation.

First attempt to build tandem perovskite-PERC/POLO solar cells achieves 21.3% efficiency

The tandem cell was fabricated by German scientists through a process flow that is compatible with industrial, mainstream PERC technologies. According to its creators, the device has the potential to exceed efficiencies of over 29% with adjustments in the perovskite thickness and bandgap.

Bifacial TOPCon solar cell with 23.84% efficiency, 90% lower silver consumption

Developed by Germany’s Fraunhofer ISE, the cell is manufactured with metallization based on a plating process. The device was built with galvanic nickel/copper/silver contacts instead of common silver contacts.