No two solar plants are ever the same, and the conditions that can impact energy yield can literally change with the wind. Soiled solar modules have long been considered a minor nuisance for the sector, but as understanding of how soiling affects output improves, so have techniques and technologies to tackle the persistent problem of dirty modules.

This pv magazine Soiling and solar special, powered by Kipp & Zonen, features articles tackling this theme, from the pv magazine global print edition, our online archive, and white papers from Kipp & Zonen.

Soiling and solar: Dust, soil, and soot get everywhere in the right conditions. And it is a rather ironic offshoot of the solar industry’s expansion that optimal dusty conditions are often aligned perfectly with optimal solar conditions.

Soiling and solar: Dust, soil, and soot get everywhere in the right conditions. And it is a rather ironic offshoot of the solar industry’s expansion that optimal dusty conditions are often aligned perfectly with optimal solar conditions. Quality testing: Since 2014 PV Evolution Labs, a subsidiary of DNV GL, has been publishing its PV Module Reliability Scorecard. In 2017, some of the key findings are that the Bill of Materials matters more than ever, and that the location of the production facility can be crucial. Jenya Meydbray, PV Evolution Labs founder, provides his take on making quality count.

Quality testing: Since 2014 PV Evolution Labs, a subsidiary of DNV GL, has been publishing its PV Module Reliability Scorecard. In 2017, some of the key findings are that the Bill of Materials matters more than ever, and that the location of the production facility can be crucial. Jenya Meydbray, PV Evolution Labs founder, provides his take on making quality count. MLPE analysis: The growth of the module-level power electronics industry has tended to bring more questions than answers, chiefly concerning the cost-performance ratio when compared to traditional string inverter solutions. And with all three types of solutions – DC optimizer, string inverter, and microinverter – each claiming to push the envelope on cost, safety and power output, is there a simple answer to the simple question: Which is best?

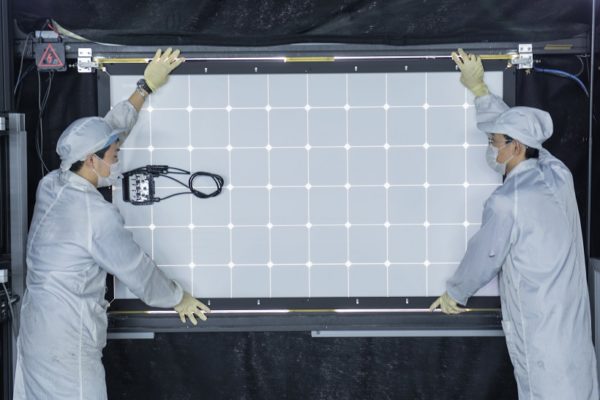

MLPE analysis: The growth of the module-level power electronics industry has tended to bring more questions than answers, chiefly concerning the cost-performance ratio when compared to traditional string inverter solutions. And with all three types of solutions – DC optimizer, string inverter, and microinverter – each claiming to push the envelope on cost, safety and power output, is there a simple answer to the simple question: Which is best? Module performance: Over the years researchers at TUEV Rheinland have tested and evaluated thousands of PV modules. Some of the individual tests performed only take a few seconds, while others (e.g. climate chamber related tests) take days or weeks to perform, but all are executed under well-controlled laboratory conditions.

Module performance: Over the years researchers at TUEV Rheinland have tested and evaluated thousands of PV modules. Some of the individual tests performed only take a few seconds, while others (e.g. climate chamber related tests) take days or weeks to perform, but all are executed under well-controlled laboratory conditions.