ads-tec

ads-tec

Stationary storage to boost e-mobility

A Porsche EV has a capacity of around 100 kWh. A typical grid connection can deliver 20 kW at 32 amps. Given this, it will take around two and half hours to charge the battery to 50% capacity. This is despite the fact that the car is the first that can be charged at 800 V high voltage with 320 kW – but of course, only if the charger can deliver that power. In that case, it takes around 10 minutes for a 50% capacity charge – around 16 times faster.

To address this challenge, German company ads-tec GmbH has developed a charging system named HPC Booster, which can produce this high voltage with the assistance of a 140 kWh battery. The stationary battery at the charging point is loaded continuously from the grid, and can be quickly discharged into the car on demand. With this product, the company assumes pole position in the 2019 Energy Storage Highlights ranking.

The HPC Booster’s footprint of just 1.20 × 1.20 m is a particularly unique feature of the system, according to ads-tec CEO Thomas Speidel. “Because of that, it can also be deployed in cities where there is little available space.”

Such locations could be in high density city districts where there simply isn’t sufficient space available for grid expansion. Speidel explains that one field application could be for urban logistics and delivery vehicles, which will run emissions free. Such vehicles have a range of 100 to 150 km and require established charging infrastructure with such fast charging capabilities.

How did ads-tec achieve the HPC Booster’s compact footprint? By utilizing silicon carbide semiconductors. The circuitry has been developed together with Fraunhofer ISE and achieves particularly high switching frequencies.

Essentially, there are two possible business models for the product. In one, it is installed as infrastructure to make restaurants, pubs, museums etc more attractive to customers. The other could involve customers paying a premium per kilowatt hour for using the fast charging solution.

Ads-tec does not publicly disclose its pricing for such systems, however it is possible to make an estimate. If a battery has a lifespan of 4,000 cycles, and costs around €500/kWh, the additional costs for charging would be around €0.05 to €0.12/kWh. Additionally, one feature of the HPC Booster is that it can provide ancillary services to the grid, which would help with refinancing. The company also says that, at least in Germany, there are subsidies available to support such installations.

The HPC Booster convinced the jury of its merit, despite their criticism that such a battery for EV charging support would only work where the intervals between car charging cycles are long enough for the battery to recharge. Speidel agrees, but says that he is convinced that there will always be sufficient idle charging points. In principle, there is enough energy available to charge electric cars, but it is not always at the right location at the right time. The battery booster can help to overcome this.

Jury comments

Mark Higgins: “It is important to unlock the deployment of fast charging infrastructure by solving the problem through battery solutions.”

Florian Mayr: “This is an important contribution to overcoming the barriers that stand in the way of widespread electrification of mobility. The window of opportunity is somewhat limited, however. Demand must be high enough to make sufficient use of the investment, but the utilization must be low enough for the batteries to recharge. In the end, one has to compare the cost of this solution with the cost and local availability of other solutions such as grid expansion.”

Logan Goldie-Scot: “Battery storage can help EV fast charger operators mitigate a number of business challenges, including demand charges and time-of-use energy rates, but it’s very site specific.”

Vattenfall, Nordex, CC4E

Vattenfall, Nordex, CC4E

Turning renewables into grid stabilizers

The fluctuating nature of renewable energy poses a challenge for network operators. At the same time though, it has opened up a market for storage system suppliers.

As ever increasing renewable penetration drives fossil fuel generators out of the overall energy mix, energy providers and grid operators are working on finding new cheaper and sustainable solutions for the provision of grid stabilization.

In an attempt to turn renewable energy resources from a liability to an asset in terms of grid stability, the utility Vattenfall, in partnership with Nordex Energy GmbH and the Competence Center for Renewable Energy and Energy Efficiency (CC4E) at Hamburg University of Applied Sciences, co-located a lithium-ion storage system with the Curslack wind farm in northern Germany.

The wind farm boasts a power of 12.6 MW, and since November has been equipped with a 720 kW/792 kWh lithium-ion storage system. The wind turbines charge the batteries and feed into the grid via a shared access point, using a specialized load management system.By co-locating the wind park and battery, the team of researchers managed to use wind energy to provide primary balancing power, as well as spinning reserve for which the project aims to develop and test business models.

Looking further out into the future, the team seeks to provide dispatching power and reactive power with their system. The technical viability is only one part of the project, as the team is also considering market regulations that would benefit such actions.

While the currently featured project charges the battery and feeds wind power into the grid, the team stresses that the research will benefit the solar industry as well.

Photovoltaics struggles with the same issues of fluctuation and could likewise benefit from co-location of storage systems. The offering of various forms of grid ancillary services could be performed in the same way by solar plus storage projects.

The project runs under the auspices of the NEW 4.0 Norddeutsche EnergieWende collaborative project. Accordingly, 60 partners comprising economic, scientific, and political actors have laid out a road map to source 100% of Hamburg and the surrounding state of Schleswig-Holstein’s electricity demand from renewables.

Jury comments

Julian Jansen: “The NEW 4.0 project is at the forefront of bringing together key stakeholders from across the energy industry to help shape how a future decentralized, low-carbon, digital, and customer-centric energy system may work.”

Logan Goldie-Scot: “Energy storage is making possible truer competition between renewable energy and thermal assets across more time frames. Pilots such as this will help build out the use case.”

Florian Mayr: “A holistic approach to proactively push for a market framework that would allow to further monetize the value of storage. Although in pilot phase, the approach and the specific topic are relevant for the industry and energy transition.”

OpenEMS

OpenEMS

An operating system for the energy transition

The OpenEMS Association standardizes the communication of storage systems on an open source basis. The software facilitates energy management systems, possible business models such as the supply of grid services, and more.

The open source system eases the financial burden on manufacturers, giving them the chance to offer grid ancillary services from their products, while not neglecting their core business.

The basis for OpenEMS is a product originally developed by German storage integrator Fenecon, which the company now releases as open source. The OpenEMS Association allows all interested parties to participate in the further development of the EMS and to use it for their projects. According to Christof Wiedmann, board member of OpenEMS and Head of Sales at Fenecon, OpenEMS is not just another standard added to existing energy management and house automation standards. “None of these existing standards cover all fields, and OpenEMS wants to use and integrate existing standards and focus particularly on the energy management in the grid which allows for business models with grid services,” he says. The jurors want to acknowledge this project’s importance in creating a standard. It is even more than a standard as it also provides the software on an open source basis. However, it is necessary to avoid multiple standards. OpenEMS seems to aim for similar applications as the openADR standard which is widely used in the United States.

Jury comments

Xavier Daval: “The open source concept is welcome to improve adaptability of EMS.”

Julian Jansen: “In a highly competitive energy storage market, the development of an open protocol to standardize energy management and enable the aggregation of systems from different suppliers is not only welcome, but will drive the advancement of business models targeting ancillary services markets.”

Trina Solar

Trina Solar

27 microgrids for the Maldives

Islands have been a market for solar and battery storage for some time, Trina Solar now presents an electrification project that takes a particularly holistic approach.

The Maldives are a group of islands with a total area similar to that of Scotland, but a combined land area only as large as the city of Edinburgh. This poses challenges for electrification, as an individual microgrid has to be planned for each of the islands, which are not connected to each other.

Trina’s microgrids project spans 14 islands. TrinaBESS, the energy storage division of the company, designed and installed the project.

Given the limited land available, the systems are distributed over multiple rooftops. The smallest array is 60 kWp and the largest 330 kWp – for a combined capacity of 2.6 MW. The battery storage units have a combined capacity of

2.6 MWh. In the second phase, Trinabess is installing a further 2.3 MW of PV, and 1.5 MWh of storage on 13 islands. It says the advantage of the new microgrids is not only that 2.6 million liters of diesel are saved yearly, but also that the grid is more robust and costs fall, given that on average a kilowatt hour from a diesel genset costs $0.70.

Jury comments

Florian Mayr: “Microgrids on islands often make economic sense today and can help to deliver insights for applications on the mainland as well.”

MAN Energy Solutions

MAN Energy Solutions

Thermoelectric energy storage

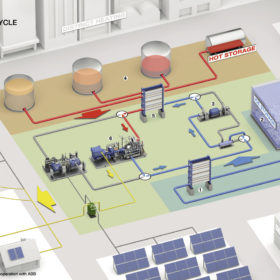

Energy storage systems are no longer a novelty, and neither are facilities powered by electricity for heating and cooling. If a device can do both at the same time, and also convert thermal energy back into electricity, such as the Electro-Thermal Energy Storage System (ETES), things become a little more interesting.

“With this approach, we are breaking down the existing silo mentality,” explains Roberto Rubichi, Communications and Marketing Manager at MAN Energy Solutions. Electricity, heat, and cooling are no longer treated separately, but become parts of a single overarching energy management system. In this process, ETES functions as a bridge between the electricity supply, and heat and cooling supply markets.

The stored cooling and heat from ETES can be distributed to different types of consumer. For instance, heat can be transferred to district heating, the food processing industry, and laundry facilities. Applications for the cooling, meanwhile, include data centers, ice hockey or skating arenas, or air conditioning for skyscrapers.

The electricity could then be used for peak shaving. Alternatively, the solution could be interesting for offtakers that require large amounts of heat, cooling, and electricity – like data centers, for example. MAN Energy Solutions is currently marketing the solution and is pursuing leads for the first pilot plant.

The majority of the facilities so far have a power output of 15 MW and thermal storage capacity of between 10 MWh and more than

1,000 MWh. Heat can be dissipated between 40 and 120°C, while cooling can be dissipated between 0 and 10°C.

Jury comments

Florian Mayr: “Breaking the silo mentality of the power, transport, and heat sectors is highly relevant for industry and the energy transition. Furthermore, the concept contains various relevant technological innovations.”

Julian Jansen: “The MAN solution cuts across traditional industry boundaries and enables effective sector-coupling by combining heat, cold, and electricity storage.”

ZAE Bayern

ZAE Bayern

Cooling accumulators in fridges help shift loads

Fridges and freezers require energy in recurring intervals throughout the day to maintain their temperature. This, however, doesn’t always have to be provided at precisely the moment of the appliance’s choosing.

A team of researchers at ZAE Bayern has developed a new approach. The team has come up with a freezer/fridge that deploys thermal storage made from a phase change material (PCM). The PCM in this case is a saline solution that freezes at -20°C. It can maintain a constant temperature for around seven hours, without the need for additional energy.

The PCM means that the fridge could be switched off overnight to save energy and be switched on again during sunlight hours. Another use case is the avoidance of ‘charging’ the fridge during peak demand hours.

Thermal storage in this way is comparatively cheap, but suffers from similar efficiency degradation and self-discharging effects that other storage technologies struggle with.

According to estimates from ZAE Bayern, around 1-2 GW of load could be shifted flexibly, if just half of Germany’s fridges deployed thermal storage like that of the ZAE Bayern solution. In the future, the technology could also be used in supermarkets or cold storage warehouses.

Jury comments

Rolf Heynen: “With the number of freezers deployed, it would have an enormous impact – to use them to shift the load to balance the grid would have a big impact. It is therefore a system innovation.”

Mark Higgins: “It is appealing that this solution allows a shift in energy consumption without any behavioral change.”

Fraunhofer IKTS

Fraunhofer IKTS

Ceramic high temperature battery works with liquid salt and sodium

The Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) developed a ceramic high temperature battery “cerenergy” for stationary storage systems. A ceramic pipe, which works as the solid electrolyte, contains molten salt of sodium chloride and nickel chloride, working as the cathode. With voltage applied, the electrolyte allows sodium ions to pass. These accumulate in the outer layers of the molten sodium, which works as the anode. All of the materials used in the system are cheap and readily available, according to IKTS. Therefore, the price for cells, when produced at scale, is forecast at below €100/kWh.

The transport of the sodium ions through the electrolyte only start at temperatures above 200°C. Good performance begins at temperatures of 270°C to 300°C, which is the constant operating temperature for the system. The battery has minimal thermal self-discharging, but is well insulated to minimize this effect. The high temperature battery cells feature an energy content of 130 Wh/kg, but a comparatively slow charge and discharge rate of 0.5C. Accordingly, this type of battery is not suitable for electric mobility, despite it being the original intended application.

Costs below €500 for the battery system allow application at scale – particularly to store renewable energy. Further possibilities are peak shaving, continuity of feed-in supply, or backup power, as these batteries have a fast reaction time.

Jury comments

Xavier Daval: “Potentially a low-cost alternative based on a basic material.”

Florian Mayr: “Commercialization is too far down the road, while the targeted system-level price point at production seems to be in the range of today’s flow batteries.”

Skeleton Technologies

Supercapacitors – fast and powerful

Supercapacitors are well suited to the provision of high power for very short times, and they can be charged up to one million times.

Skeleton Technologies has high power industrial cells (Skelcap) and modules (Skelmod) in its portfolio. The company says that it has developed and patented a manufacturing process by which it can produce curved graphene. The material boosts the voltage inside the cell to more than 2.85 V. This increases the energy and power density of supercapacitors. The product also features a very low series resistance, which in turn reduces heat build-up. The Scottish island of Eigg is an example of where the Skelcap/Skelmod energy package could be deployed. The island with its 100 inhabitants is not connected to the mainland U.K. grid, and covers its electricity demand through a 174 kW renewables portfolio. A lead-acid battery storage system helps to balance fluctuations in generation.

However, in the event of a very sudden peak load, a brownout of several seconds can occur. After this, the battery requires several minutes before it can resume normal operation, says Olivier Chabilan of Skeleton Technologies. To give the battery time to slowly reboot, the local energy provider deploys flywheels and the supercapacitors of Skeleton. Only the supercapacitors, however, are fast enough to ensure that changes between the energy sources go unnoticed.

Also, the combination of supercapacitors with lithium-ion batteries is a good match. A study on supercapacitors, published in the journal Energy in 2012, showed that a hybrid system combining the two technologies in vehicles marginally boosts range, but did improve performance and efficiency of the battery. Furthermore, the combination also allowed operation of the battery in a less strenuous way, increasing its lifespan by 40%.

The jurors see that this is a “useful application with small overall market segment targeted”. Another notes that it is unclear whether prolonging battery life justifies additional investment in a supercapacitor.

DNV GL

Keeping score of battery performance

DNV GL has released its first annual Battery Performance Scorecard, to provide advice to product buyers. The testing and certification body says that the new scorecard can independently rank and evaluate battery products.

The scorecard aids the energy storage market by providing transparent, easily verifiable data with independent engineering reviews.

In its current form, the scorecard evaluates battery systems on several criteria. At first DNV examines whether the average state of charge (SOC) is optimal for performance. Furthermore, the scientists look at which SOC window shows the best performance for each product. Additional factors include the battery C-rate (the rate at which a battery is discharged relative to its maximum capacity), as well as the product’s temperature behavior. Of the batteries tested, 88% were based on lithium-ion nickel manganese cobalt chemistry.

Hitherto, the level of battery lifetime data available to buyers was often varied and inconsistent, which is precisely the gap the scorecard aims to fill. According to DNV GL investors or developers request information on each battery type from the manufacturers, to review the product in an independent engineering report.

This process can take several months. This time can be reduced through the independent scorecard, and hence accelerate the industry.

Jury comments

Xavier Daval: “Our industry needs independent point of view frameworks to support a sound development.”

Logan Goldie Scot: “The scorecard is a crucial first step in helping differentiate between battery technologies and ultimately providers on quality. This opaque industry needs it.”

Proton Motor

Proton Motor

Fuel cell provides real year-round self sufficiency

Proton Motor delivered its hydrogen fuel cell to the world’s first entirely self-sufficient, multi-family home in Brütten, Switzerland in the summer of 2016. The electrolyzer uses 14.5 kW to produce 2 Nm³/h of hydrogen. In total, the system can hold 120,000 liters of hydrogen.

The fuel cell by Proton Motor produces 6.2 kW of electrical power and 5.5 kW of thermal power.

The electricity is transferred to the battery systems using the fuel cell’s integrated power electronics. The heat is dissipated to heat pumps for space and water heating.

Project leader Umwelt Arena Schweiz argues that using excess heat from electricity production enables efficiencies above 90% during winter months. During summer when heating is reduced or not needed at all, efficiency ranges between 18% and 19%.

A 79 kW rooftop PV system powers the house, alongside a 46 kW thin film PV system mounted on its facades, totaling 126 kW, or 90,000 to 105,000 kWh per year, for the nine families living in the unit.

The building’s energy consumption was 2,200 kWh per housing unit a year, which is about half the Swiss average. The company also stresses that its system survived its first winter, even though it was the coldest in the region in 30 years, and the one featuring the fewest hours of sunshine in 20 years.

The building features an array of energy storage technologies, including battery storage, a hydrogen electrolyzer, and a hydrogen tank, as well a long-term thermal storage tank. The combination of these long and short-term storage systems enables round-the-clock and round-the-year energy supply, without the need for any electrical grid or gas supply connections.

The project was supported with public funding. According to the company, it demonstrates the technical feasibility for a solution that becomes increasingly viable at larger scales. When increasing the production numbers, the cost for the electrolyzer would fall to a quarter. The cost target was hydrogen production at between €2 to €3/kg.

Each tenant receives an energy budget included in their rent. When this is exceeded, they incur an additional fee, while staying below the budget results in a financial reward. According to the project leader Umwelt Arena Schweiz, the rent is at the higher end of the scale for the region.

Jury comments

Rolf Heynen: “These sort of pilots go far beyond 60% or 70% autarky and therefore they contribute more to the learning curve on the system side.”

Xavier Daval: “The usage of multiple storage and renewable technologies is interesting.”

Fraunhofer IGB

Fraunhofer IGB

Chemical plant at wind park can replace petroleum products

Fraunhofer Institute for Interfacial Engineering and Biotechnology (IGB) presents a solution which can turn water and CO2 into hydrocarbons. This would allow an important chemical industry to switch to renewable energy.

Like in a power-to-gas facility, the process starts with the production of hydrogen through electrolyzation using a renewable energy feed stock, such as power from a wind turbine. Methanol can then be produced by routing a mixture of hydrogen and carbon dioxide through a copper-based catalyst. Methanol is already a valuable staple for chemical production. But since it is produced at industrial scale, small facilities are not lucrative, says Lénárd-Istvan Csepei, who is responsible for chemical energy storage and bioelectrical and chemical catalysis at Fraunhofer IGB in Germany.

Csepei’s team has developed a technology that can transform methanol into more valuable products. The process involves feeding methanol to a Methylobacterium, which produces isoprene, lactic acid, polyhydroxybutyric acid, and long chain terpenes. Isoprenes can be processed into high energy fuels. Other by-products can be used in rubber plastics or in the food and fodder industries. Csespei says that their market value lies between €1,100 and €5,000 per metric ton, As a result, small-scale production at distributed assets would be viable. The project is supported by the European Commission and the state of Bavaria.

Jury comments

Mark Higgins: “Very interesting and potentially valuable technology for the energy transition.”

Florian Mayr: “Specific relevance for storage industry not clear, but potentially very relevant for CO2 valorization.”

Ecovolta

Ecovolta

Medium-sized car brands can enter e-mobility with traction battery

Many large car manufacturers have already decided to establish their own battery production. Many smaller manufacturers, however, lack the resources to follow suit. For such companies, Ecovolta has developed an offer: a standardized modular and scalable battery named the evoTractionBattery. The product was conceived for auto manufacturers with a throughput of up to 2,000 vehicles per year, for example municipality-owned utility vehicles, road sweepers, golf carts, forklifts, or boats. Other options are buses or trucks which need extra battery capacity for use in mountainous regions.

The batteries comprise lithium-ion cells and have a capacity of between 2.5 and 15 kWh. Modules can be interconnected in series or in parallel for further scalability. Contrary to many other batteries on the market, Ecovolta’s product has already undergone all relevant certification and security standards processes, which are required for applications in vehicles. Through the company’s second branch, Ecocoach, which develops stationary battery systems, second-life use cases are planned for the future.

According to Ecovolta, the battery lowers the investment barrier to enter into the e-mobility market by up to €500,000.

Fronius

Fronius

Three phase, high voltage storage, plus emergency power

Fronius describes the unique feature of its residential solar+storage inverter, Fronius Symo Hybrid as the only device which uses technology from Chinese battery manufacturer BYD, operates three-phase, and can provide emergency power. Consequently, it is worth a closer look.

Low-voltage residential storage systems with emergency power supply have been available for several years. And for some time, high-voltage systems have become more common, since using the battery at higher voltages improves efficiency.

Competitors have launched battery inverters specifically designed for BYD’s high voltage battery, which is said to be economically attractive. Some are AC-coupled, one phase and provide emergency power. Others are three-phase DC-coupled systems which cannot. The DC-coupled Fronius device can do both, with a BYD battery sized at between 6.4 and 11.5 kWh. The emergency power function in an electronic device necessitates the use of a neutral conductor. This can negatively affect efficiency by around 0.2 to 0.3%, and for this reason others don’t offer emergency power. Fronius developed a circuit that excludes the neutral conductor from the current when emergency power is not required. Given this, the Fronius inverter delivers the same efficiency if it had no emergency power functionality.

Xelectric Power GmbH

Xelectric Power GmbH

Xelectric Powerbox – a fire resistant multipurpose battery

Rising costs of energy, grid taxes, and partially insufficient grid supply: These are just some of the key drivers for businesses to install energy storage systems.

Austria-based battery storage company Xelectric Power GmbH has launched a multipurpose modular storage system for utilities, commercial and industrial customers, construction sites, and essentially all on and off-grid applications. The capacity of the system ranges between 20 kWh and 2.4 MWh and its power between 12 kW and 1 MW.

The company says that its unique bidirectional hybrid inverter is key to the system’s ability to provide multiple use cases in a single piece of equipment. The system can, for example, provide peak shaving for businesses, but also be used for reactive current compensation, as well as voltage and frequency control.

Additionally, the Xelectric Powerbox can provide three-phase backup and function as an uninterruptible power supply.

Since the inverter works in parallel to the grid, it can easily combine grid power, on-site renewable energy generation, and energy from the storage system to provide higher power availability for the customer, without the need for grid expansion.

With increasing EV uptake in the commercial sector, this solution will become more and more important, the company states.

In addition to making available more power for a company and reducing the energy bills by avoiding peak demand, the storage system also features a self-extinguishing system, which sets a new bar for fire safety in lithium-ion battery systems.

Kaco New Energy

Kaco New Energy

Bidirectional battery inverter for C&I storage

Inverters are in a unique position in the energy system, as they connect various actors, like batteries, consumers, prosumers, and utilities. This has played out to the effect that inverters have increasingly started to take on energy management tasks, resulting in the equipment often being dubbed the ‘brain’ of the energy system. With the blueplanet gridsave 50.0 storage inverter, Kaco New Energy has stripped the inverter of any proprietary communication protocols, and so dubbed its new inverter the ‘muscle’ of an energy storage system.

The inverter uses the standardized Sunspec communication protocol. Kaco claims that due to the lack of a proprietary protocol, the system is compatible with a large range of energy management systems, thus increasing its range of application. At the time of developing the BG50 inverter, a plethora of battery management communication protocols had been developed already. The goal was to allow system integrators to use their existing energy management system protocol to operate the inverters.

According to Kaco, the solution was developed with public utilities, distribution system operators, EPCs, and large businesses with grid management in mind. Such enterprises would often have their protocol standards ready.

Developing a proprietary protocol would have ensured that such a protocol was compatible with other existing ones. By using the Sunspec standard this could be avoided.

Kaco’s blueplanet gridsave 50.0 kW inverter can be interconnected in parallel on the DC side. This allows for a system design that connects several inverters to a single high-capacity battery. According to the company, the modular approach makes it possible to deploy the BG50 storage inverter in energy storage systems of multiple sizes in commercial and industrial installations.

REFU Elektronik GmbH

REFU Elektronik GmbH

Modular battery inverter provides more C&I flexibility

To accommodate the demand for fast charging and discharging of industrial-scale battery storage systems, integrators have often used central PV inverter designs. According to inverter manufacturer Refu, this conflicts with a system’s design flexibility, price, battery control, and ease of installation. For applications between 60 kW and 1 MW, central inverters may be oversized or not fit appropriately.

Therefore, the company launched its battery inverter, REFUstore 88K, to provide the possibility for a wall-mounted and scalable power conversion unit. The unit’s power density is rated at

1.3 kW/kg. A wide DC voltage window from 280 VDC up to 900 VDC, enables the device to be used for new as well as second-life battery applications.

Furthermore, the inverter can be used in small and large systems by adding more units in parallel on the AC side. The company says that clustering smaller units simplifies battery and inverter cabling and increases system reliability. Additionally, with the use of multiple smaller units, each battery rack can be controlled, charged, and discharged separately. This allows for improved battery management and thus a longer lifetime of the system.

According to Refu, system integrators are faced with a great diversity of customer requirements, like DC and AC fuses, switches, surge protection devices, or pre-charge circuits. To be able to meet this variety at a competitive price point, Refu says that it has reduced the design effort, by deploying a flexible and modular system. This was achieved by manufacturing the connection box and the power unit separately. For the installation, the connection box can be selected with the correct cabling layout. The power unit is then mounted onto the connection box once all of the cabling is completed.

Hoppecke

Hoppecke

Scalable turnkey solution for storage

With its latest offering, Germany’s Hoppecke aims to provide a turnkey battery energy storage solution, and a standardized system designed to limit the costs arising from project-specific configurations and planning. The system could easily be scaled for projects up to 500 kWh.

The sun systemizer scalebloc is a complete battery energy storage system, to be sold as a turnkey solution.

Each unit comprises a 60 kWh lithium-ion battery, 30 kW battery inverter, integrated cooling system and an outdoor housing cabinet with IP55 protection.

The batteries in Hoppecke’s system are based on nickel manganese cobalt chemistry, and a standardized 19-inch battery module.

According to Hoppecke, the system has a wide range of potential applications, including e-mobility infrastructure, local stationary storage, peak shaving, and various off-grid applications.

Scalebloc is AC-coupled with black start and island mode capabilities, and comes with cloud connection, which Hoppecke says will enable the customer to easily operate, manage, and service the system.

Hoppecke says that the systemizer scalebloc is still currently in the development phase. However, it notes that initial field test customers have been identified and that plans on the service and manufacturing side are also under development.

Raycap

Raycap

Safe and sound surge protection

With the ProBloc B 1000 DC, the United States-headquartered company Raycap will release a surge protective device (SPD) universally suitable for e-mobility applications.

Due to its combination test as both a type 1 and type 2 arrester, the SPD can be used universally in e-mobility applications as either lightning or surge protection.

A rated impulse voltage of 2.5 kV must be guaranteed for electric cars. So, the SPD, with correct wiring, also takes over the protection of the electric car to be charged.

The optical display offers an overview of the status of the product and, with its telecommunications contact, also the possibility of monitoring via the control system or remote signalling.

An important aspect is the protective function for temporary overvoltage (TOV). Here the product offers safety up to 1,000 VDC.

On top of this, the application stands out in that it offers a protection level of <2.3 kV according to the company. This ensures that electric vehicles are also protected.

In addition to its compact design, the ProBloc B 1000 DC offers a special high-performance disconnecting device, which allows for the elimination of an occurring arc.

Due to the system’s high self-extinguishing capacity, a prospective short-circuit current of 30 kiloamperes, which could be caused by a battery, can be separated.

The company says that its SPDs offer a high degree of protection, not least because the device fully omits the use of materials which could burn, smoke, or explode.

E3/DC

E3/DC

Solar, storage, and optimized energy management, coupled with behavioral incentives in alpine apartment living

In May 2018, the SonnenparkPLUS, housing up to 10 families, opened in Wetzikon, Switzerland. The building features an 81 kW PV system mounted to its roof and facades. Combined with a 78 kWh battery storage system provided by E3/DC, the building is said to be 63% self-sufficient. The 1,705 m² area requires 65,000 kWh, of which 15,000 kWh alone are needed for heat pumps.

During the summer months, the building is effectively self-sufficient and even feeds energy back into the grid. During Switzerland’s cold winter season, however, this degree of self-sufficiency cannot be maintained. The behavior of the building’s residents also plays an important role.

The SonnenparkPLUS storage and energy management system is central to its high level of self-sufficiency, as it guides the building’s appliances to consume in a solar-optimized manner. Electricity produced on the rooftop array is first of all used to generate heat, and cool the building using high efficiency heat pumps. At the same time, the battery is charged with PV power, enabling grid independent operation even after the sun goes down. As a third priority, the system feeds into the grid. This means that the residents are advised to perform appliance-based chores during daylight hours, to make the best use of the PV electricity from the rooftop.

The project was designed by Swiss architects firm arento AG. The approach is described as holistic, by combining ecological building materials, energy efficiency, and renewable energy. The first priority was to design the house in a way that consumes as little energy as possible. “We have a superior building envelope: We use highly efficient heating and ventilation systems,” explains arento AG’s owner Franz Schnider. “Additionaly, we train our customers in terms of energy consumption.”

The house features an EV which is available to the residents to share via an app. The car is charged using a

22 kW charger, which is also fed by the PV and storage system. The building features only one meter point connected to the grid operator, to calculate loads that had been fed into the grid or consumed. Inside the building, electricity costs for household and mobility are calculated on a household basis using individual meters. Sustainable usage profiles, which maximize self-consumption then pay off for the individual tenant, providing an incentive for such behavior.

Tesvolt

Tesvolt

Municipal storage and self-sufficient living quarters

In the first of two projects Tesvolt wishes to highlight, the company co-located a 4 MWh battery system with a 7.4 MW solar plant in Westhampnett, in the U.K. According to the company, it is the first solar+storage installation operated by a local council in the country.

The PV plant is also among the first in the U.K. that can operate without subsidies. The storage system earns its keep via price arbitrage, frequency services, capacity market payments, and minimizing consumption during peak periods.

Tesvolt’s second project is aimed at improving living conditions for construction workers in the Middle East. Consolidated Contractor Company developed a trailer for workers. Despite working off-grid, the trailer can be supplied with round-the-clock air conditioning thanks to its PV and battery system. Even when outside temperatures are a scorching 50°C, the trailers could be kept at a comfortable 25°C. During the day the trailer is used as an office, and as a sleeping quarters at night.

The storage system has a capacity of 28.8 kWh, and 6.5 kW of power. Tesvolt says one of the advantages of its system is the minimal space requirement of the prismatic battery cells the company uses.

H-TEC Systems

H-TEC Systems

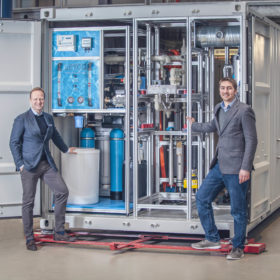

Regional sector integration with green hydrogen mobility project

Project developer eFarming GmbH & Co. KG is establishing a first-of its kind mobility infrastructure in the German coastal region of North Frisia. The project aims to provide green hydrogen to local public and private transport.

H-TEC Systems supplied five of its ME 100/350 PEM electrolyzers, to be co-located with five existing wind farms, to the project. Units are enclosed in 20 foot (6.1 meter) containers, giving flexibility with regards to location.

It is also possible to dissipate the process heat from hydrogen production through the local heat supply.

The system produces hydrogen according to the SAE J2719 standard for use in fuel cell vehicles, and delivers the hydrogen at a pressure of 30 bar. This enables direct further utilization via storage, transport, and fuel. At a nominal electrical load of 225 kW each, the five electrolyzers will produce a total of up to 500 kilograms per day, allowing up to 17 hydrogen-powered buses to be fuelled daily. The coastal region in Germany, with a high penetration of wind power, is facing increasing congestion in its electrical grid, and feed-in tariffs are coming to an end for the local pioneers of wind power. Such an integral project approach could be the role model for deployment in various locations to promote regional self-sufficiency.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.