Shedding light on tandem perovskite solar cell progress

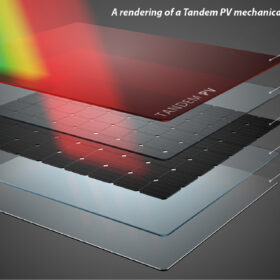

Perovskite PV devices are set to become the next big thing in solar with market analysts at S&P Global Commodity Insights predicting 1 GW of production by the end of 2024, rising to 6 GW in 2025. Perovskite tandem devices are at the front of the queue for commercialization but their characterization presents technical challenges.

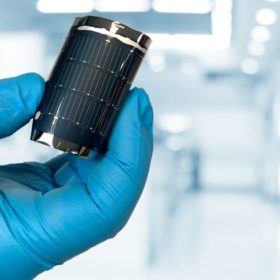

Weekend Read: Flex generation

A new generation of flexible, lightweight modules is entering the market. With back contact technology offering its own form of design flexibility and robustness, the new products could crack a hard-to-address market segment.

Weekend Read: Pushing perovskite PV limits

The perovskite solar race is heating up, with a cue of manufacturers forming to test products at the US Department of Energy’s (DoE) PV commercialization facilities, and academics on both sides of The Pond announcing new advances in recent months.

Shanghai Electric sounds death knell for CIGS manufacturing project backed by $197m of public money

With five public entities having committed RMB1.25 billion into a project to produce copper, indium, gallium, selenide solar modules five years ago, the joint venture has been abandoned at an estimated impairment cost of RMB1.42 billion.

Norwegian investor raises stake in company developing ‘perovskite-boosted’ solar cells

Swedish business Evolar is working on a bolt-on piece of production equipment which would upgrade the cell lines of conventional manufacturers with a perovskite lift in performance.

Swiss scientists achieve 21.4% efficiency for flexible CIGS solar cell

The result was confirmed by Germany’s Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE). The cell was fabricated through a low-temperature co-evaporation method for the growth of the light-absorbing CIGS semiconductor thin film.

Raising crops in PV facades

An international research group has analyzed the visual impact of PV facades on buildings which include crop cultivation. Architects, PV specialists and farmers were surveyed and the results showed broad acceptance of such projects.

Flixbus fleet tests 18% CIGS panels

After announcing plans to test hydrogen fuel cell buses in November, the European coach travel route planning start-up has begun a pilot project to reduce diesel consumption by using solar panels on the vehicles of its partner companies. FlixBus says the ultra-thin, lightweight CIGS modules help save 1.7 litres of diesel per 100km.

Singulus scores €50m CIGS production kit order from unit of China’s CNBM

The German PV equipment provider has agreed to supply manufacturing equipment for CIGS thin-film solar panels to the CNBM Bengbu Design and Research Institute for Glass Industry, a subsidiary of cement producer China National Building Material.

Nice Solar Energy sets new world record for CIGS efficiency

Chinese-German JV Nice Solar Energy has set a new world record of 17.6% efficiency for a CIGS module with a 0.72m² surface. The achievement has been confirmed by German testing organization TÜV Rheinland.