PV module recycling gains momentum as waste volumes surge globally

A comprehensive new report from IEA PVPS Task 12 reveals how countries around the world are managing the growing volumes of end-of-life solar modules, implementing regulations and scaling recycling infrastructure to handle the expected increment in PV waste over the coming decades.

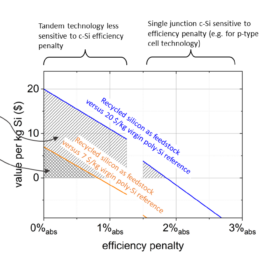

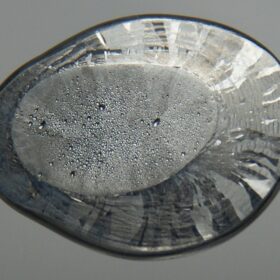

Prospects for reusing silicon from end-of-life solar modules in new ingot production

Scientists in the Netherlands proposed a new testing scheme for recycling silicon from end-of-life photovoltaic panels. Their methodology helped create different wafer categories for recycling silicon for new ingot production but also showed that most of recycled silicon in the near future will come from p-type products, which will harldy be reutilized in a market now dominated by n-type modules.

Italian startup develops thermo-mechanical PV panel recycling process

Venice-based 9-tech has developed a thermomechanical process to recycle end-of-life PV panels, with early results showing an 87% recovery yield of materials such as silicon, copper, and silver.

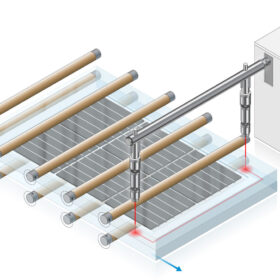

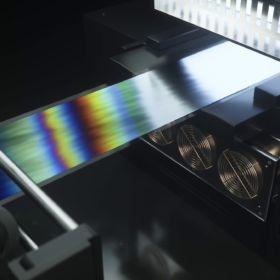

Improving solar panel recyclability with lasers

The National Renewable Energy Laboratory developed a proof of concept for a method to remove polymers from solar panel manufacturing to enable more efficient recycling.

Perovskite thin film: Out with the old, in with the new

Silicon-perovskite tandem solar requires optimization of both approaches, and embodies the weaknesses of each. Meanwhile, the use of pure thin-film devices offers a cheaper, simpler, and more sustainable PV solution for the United States.

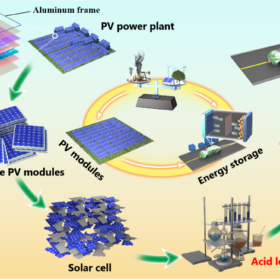

Solar waste to provide material supply security

Researchers from the University of New South Wales have rejected suggestions that end-of-life solar panels could create a “waste mountain” in Australia, saying instead that they could serve as valuable material reservoirs for future production.

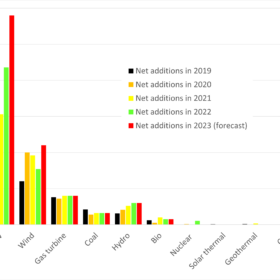

Solar panel waste is not a significant problem

Solar panel waste will not be a problem because there is so little of it. However, there is a short-term problem in some places because panel deployment is growing fast and recycling is playing catch up.

Netherlands raises solar panel recycling fee to ‘absorb shocks’ in market

PV module importers in the Netherlands saw the solar module recycling fee increase from €6.50 ($6.8) per ton to €40 per ton in July. In a chat with pv magazine, Jan-Willem Jehee, operations manager at Stichting Zonne-energie Recycling Nederland (ZRN), explains the money generated from the fee hike will be used to finance a guarantee fund that would ‘absorb shocks in the market should one occur.’

New technique to recover lead in end-of-life solar panels

A research group in the United States has developed a process to recover lead in its metallic form so that it can be reused in the PV industry. The process relies on a leaching solution based on a combination of acetic acid (CH3COOH) and hydrogen peroxide (H2O2), which the researchers said leaches the lead ‘in a matter of minutes.’

Reusing silicon from end-of-life photovoltaic modules for battery anodes

Scientists in China have proposed to use recycled silicon from discarded solar cells to build anodes for batteries. They combined the recycled waste silicon powder with graphite and created a composite material that is claimed to exhibit remarkable electrochemical performance.