Swedish startup testing silicon anode battery material

Sweden-based Green14, a plasma silicon startup, said its silicon-based anode material is being tested by the battery group at RISE, Sweden’s national research organization.

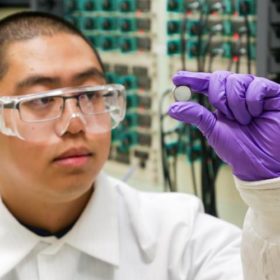

GDI unveils 100% silicon anode for rapid charging, higher energy density

Third-party tests of GDI’s 100% silicon anodes show that they offer more than 30% energy density than graphite anodes, allowing for 15-minute rapid charging up to 80% state of charge (SOC) for hundreds of times back to back.

The mobility rEVolution: Novel anode material paves way for 15-minute EV charging

US researchers have developed a novel fast-charging battery anode material, and GM has revealed a new focus on battery R&D. The European Parliament, meanwhile, has issued a number of proposals for alternative fuels infrastructure.

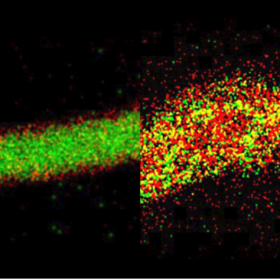

Observing silicon anodes in action

Scientists in the United States working with silicon anodes for lithium-ion batteries have managed to model key mechanisms that lead to fast developing performance loss in the anodes. Understanding what causes the silicon to swell up and subsequently fall apart, the scientists say, is an important step to preventing it, and producing long lasting, high-capacity batteries.

Silicon for batteries moves to commercial production

U.S. company Group14 Technologies today announced the launch of a factory capable of producing 120 tons per year of its innovative silicon-carbon-based anode material for lithium-ion batteries. The factory is located at Group14’s headquarters in Woodinville, Washington and is the first of several planned by the company.

New method to produce silicon anodes for lithium-ion batteries

Scientists in Sweden developed a new aerogel process to manufacture silicon anodes for lithium-ion batteries, promising to offer batteries with greatly increased capacity compared to those on sale today. By growing nanometer-sized particles of silicon onto graphite, the group was able to demonstrate a device that overcomes many of the challenges common to silicon as anode material. While there are still challenges in terms of stability and capacity retention, the approach could ultimately yield low-cost, large-scale production processes.

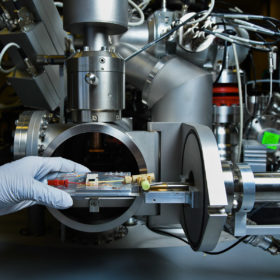

Carbon nanotubes pave the way for silicon in storage

Scientists in the United States have developed a carbon nanotube method of fabricating a lithium-ion battery with a silicon anode. The device reportedly demonstrated better than 87% capacity retention after 1,500 cycles. The developers say their discovery overcomes many of the obstacles to the use of silicon as an anode and could open up the use of other materials for electrodes in lithium-ion devices.

An alumina lining for silicon in storage

Scientists at Rice University in the U.S. have conducted experiments with lithium-ion batteries using silicon as an anode material and made an unexpected discovery regarding an aluminum oxide passivation layer at the cathode. The finding could open up a new pathway toward better performing lithium-ion batteries.