Multi-junction solar cell integrating radiative cooler

The triple-junction solar cell is based on indium gallium phosphide (InGaP), gallium arsenide (GaAs), and Germanium (Ge) and is made with a micro-grating made of glass, consisting of a two-dimensional x-framework structure fixed onto the surface of the solar cell. Its operating temperature was found to be 6 degrees Celsius lower than that of a reference cell without the cooling technique.

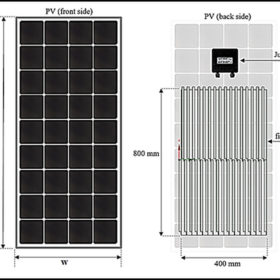

Multi-level fin heat sinks for solar module cooling

Developed by Malaysian scientists, the proposed multi-level aluminum fin heat sinks (MLFHS) were found able to reduce the module operating temperature by up to 8.45 degrees Celsius and increase power yield by up to 10.75%. The system cost was estimated at $0.60/W.

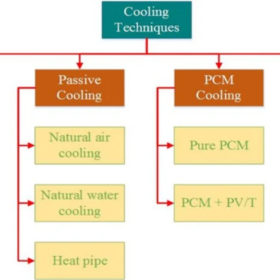

PV module cooling techniques at a glance

Egyptian researchers have analyzed all cooling techniques for solar module cooling. Their review includes passive and active cooling methods, cooling with phase change materials (PCMs), and cooling with PCM and other additives, such as nanoparticles or porous metal.

Spraying water system for solar module cooling

A British-Indian research group has developed an active cooling technique that is claimed to improve a PV system’s yield by around 0.5%. The system could be used in residential solar arrays and the water heated by the PV modules may be fed into a solar water heating system.

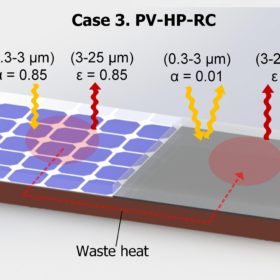

Lowering solar module temperatures with radiative cooling, heat pipes

Chinese scientists have developed a hybrid cooling technique to reduce module temperatures by up to 12.86 C and increase power yields by 7.25%. Their system features a PV module and a separate RC module, integrated with a flat plate heat pipe in between.

Cooling PV panels with water and cotton mesh

Scientists in Russia have developed an active cooling technique that spreads water on both sides of the module and uses a cotton wick mesh to absorb and spread the water that comes on the rear side. The system is able to reduce significantly a module’s operating temperature and lead to an overall improvement of 30.3% in its output power.

Cooling solar panels with thermoelectric modules

The cooling system was made with an aluminum heat sink and a thermoelectric module. The solar panel is cooled exclusively by the thermoelectric device, which is, in turn, cooled down by the heat sink via free convection. According to the scientists that developed the technique, it was able to reduce panel operating temperature by about 10 degrees Celsius.

Green roof improves solar panel efficiency by 3.6% on average

The comparison of two solar cladded roofs in Sydney, Australia, one bare beneath its panels and the other adorned with native grasses and plants, has found the panels on the green roof were, on average, 3.63% more efficient, producing an average daily output 13% greater than the conventional roof. The improvements are believed to stem from the lower temperatures on the green roof, thanks to its plants – which also provided a plethora of additional benefits.

Cooling PV modules with plants, coir pith

An Indian-Malaysian research group has investigated the effectiveness of several passive cooling techniques for solar panels, including the placement of plants around the modules or coir pith underneath them, both of which, surprisingly, offered good performance in terms of temperature reduction and power yield.

Conical-shaped solar panels cooled by forced airflow

A group of international scientists has compared the hypothetical performance of three novel shapes of solar modules – pyramidal, hexagonal and conical – and has found the latter has the strongest potential in terms of thermal behavior. According to their findings, a cooling technique based on forced airflow is key to making these solar module shapes into a feasible solution.